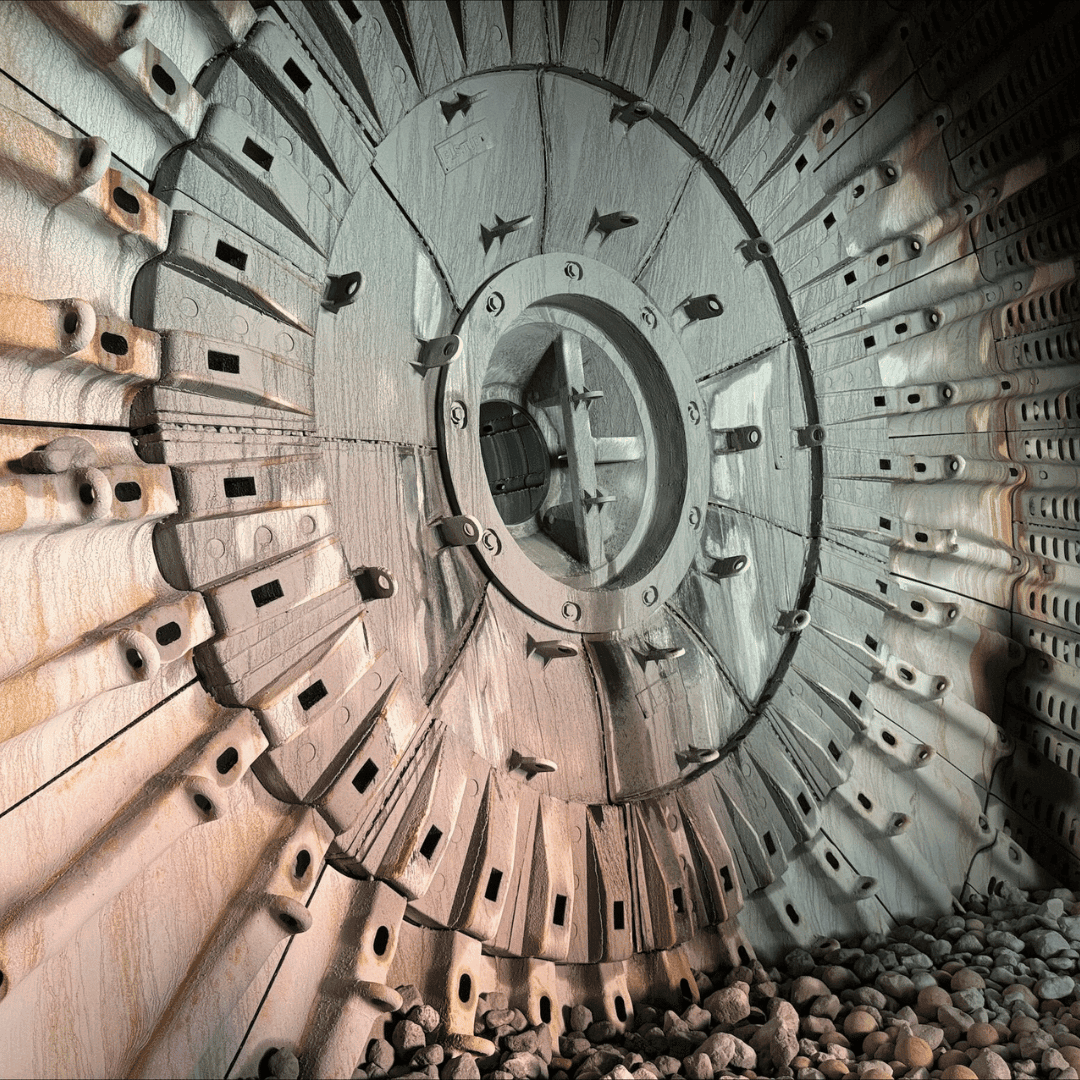

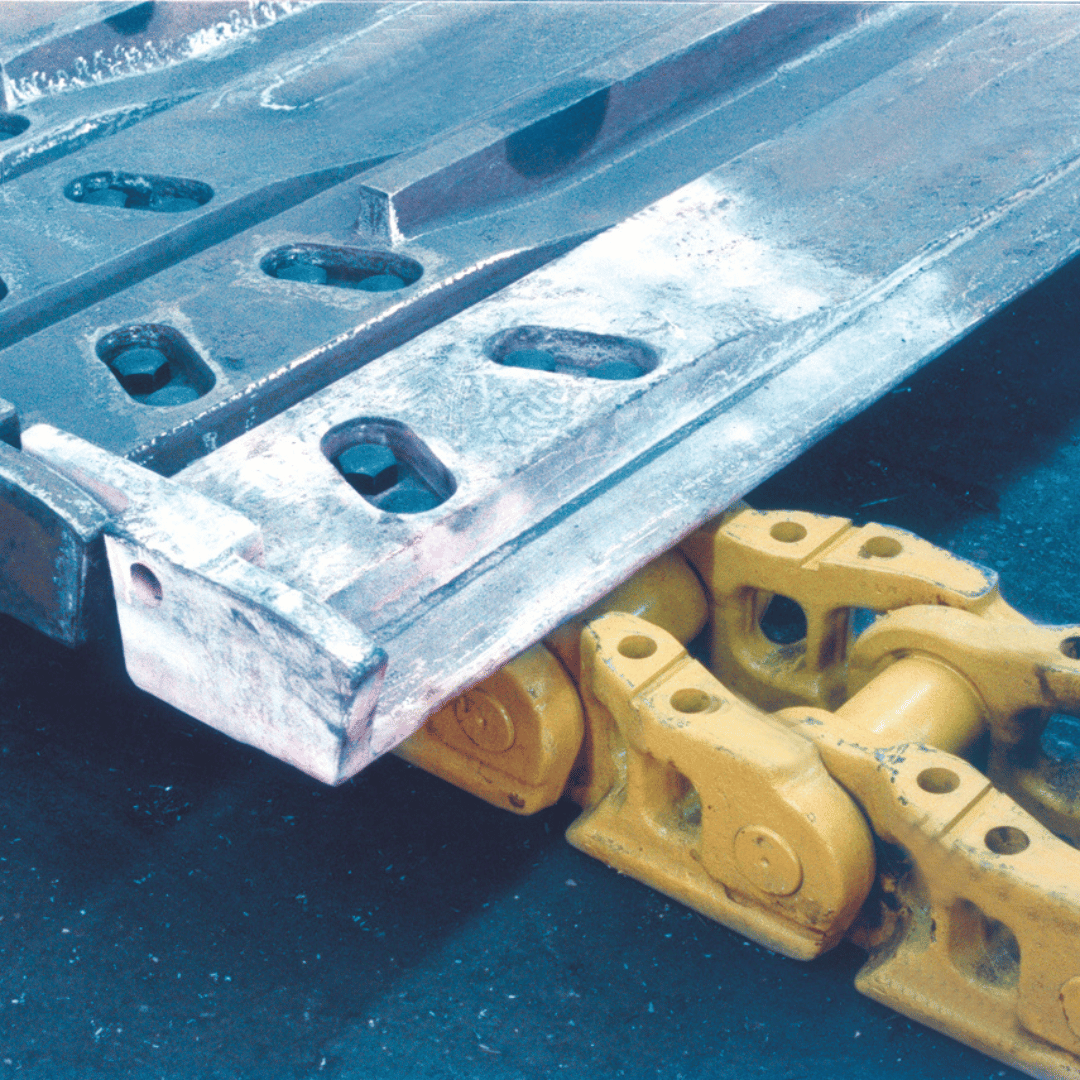

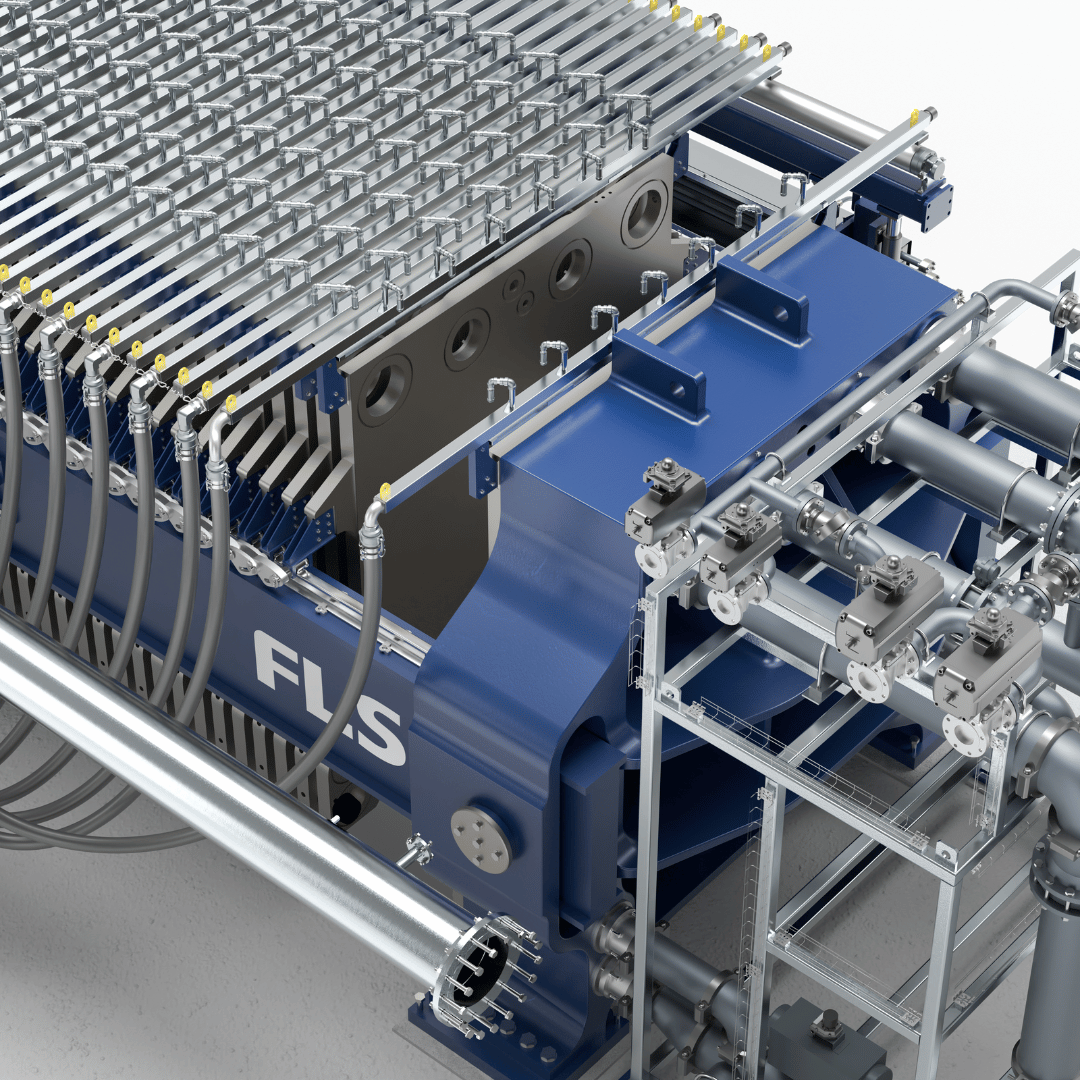

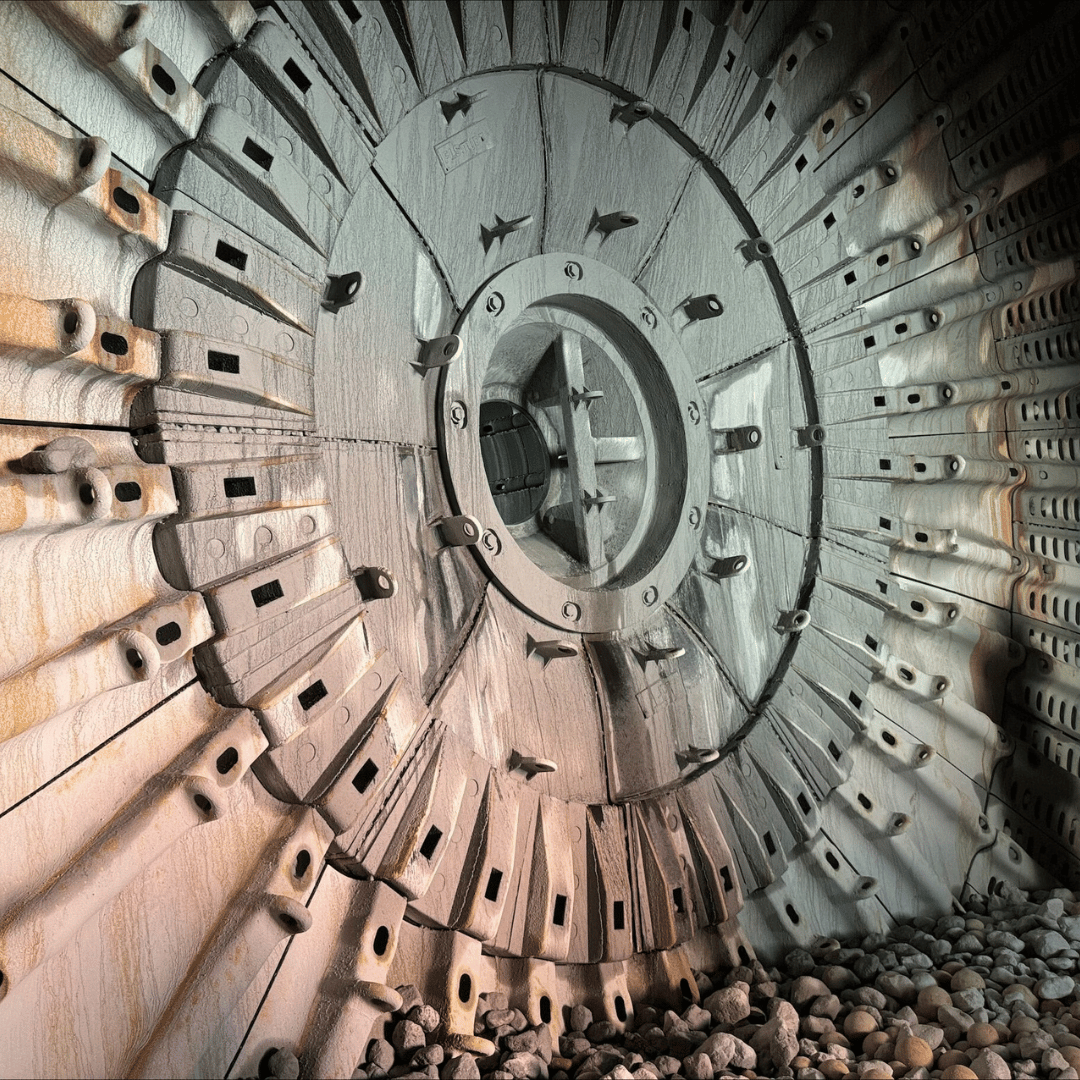

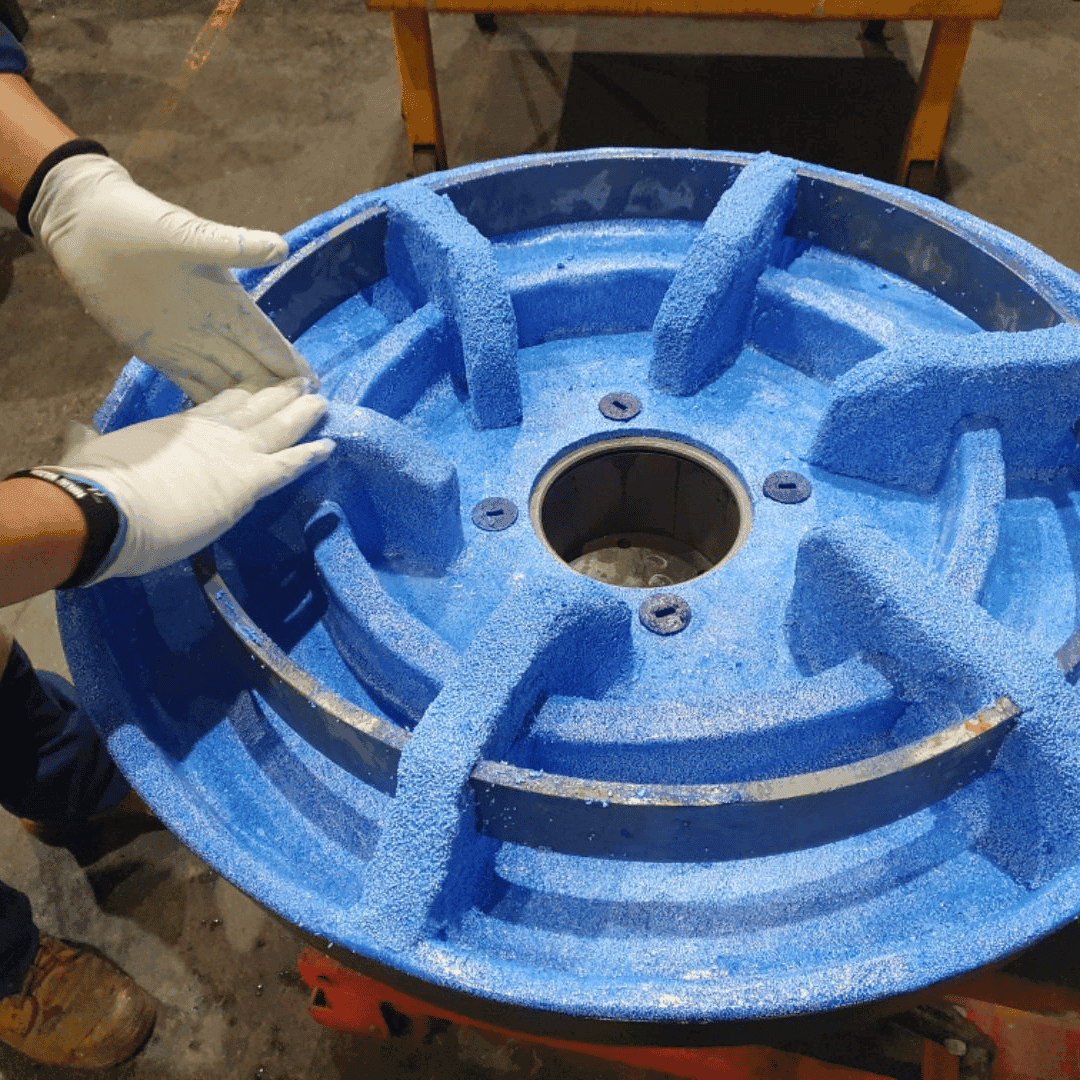

From crusher to thickener – a broad portfolio of consumables

Our full flowsheet services are supported by our global service network, including both expert engineers and state-of-the-art technology, so we can supply both wear parts and accompanying services, wherever you are. Bundle wear parts with digital services such as Asset Optimisation to achieve further increases in efficiency and uptime and reduce the environmental impact of your process.