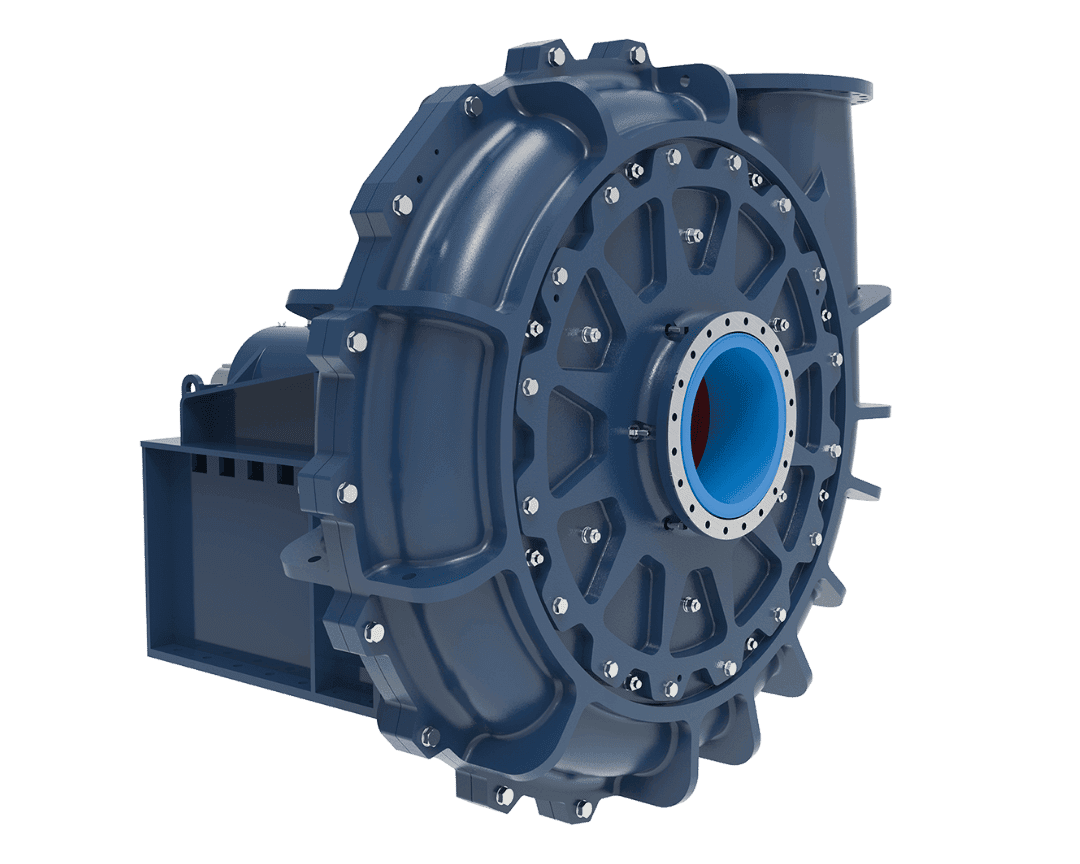

High-efficiency pumping

Our proprietary adjustable wear ring technology enables quick, easy, and safe control of suction-side clearance while the pump is operating. By closing the gap and preventing recirculation within your pump, while also avoiding the grinding of solids between the impeller and suction side, our wear ring technology ensures design performance is maintained throughout the pump’s life—without the need to increase pump speed. This results in lower power consumption, extended wear life, and a reduced cost per tonne pumped.