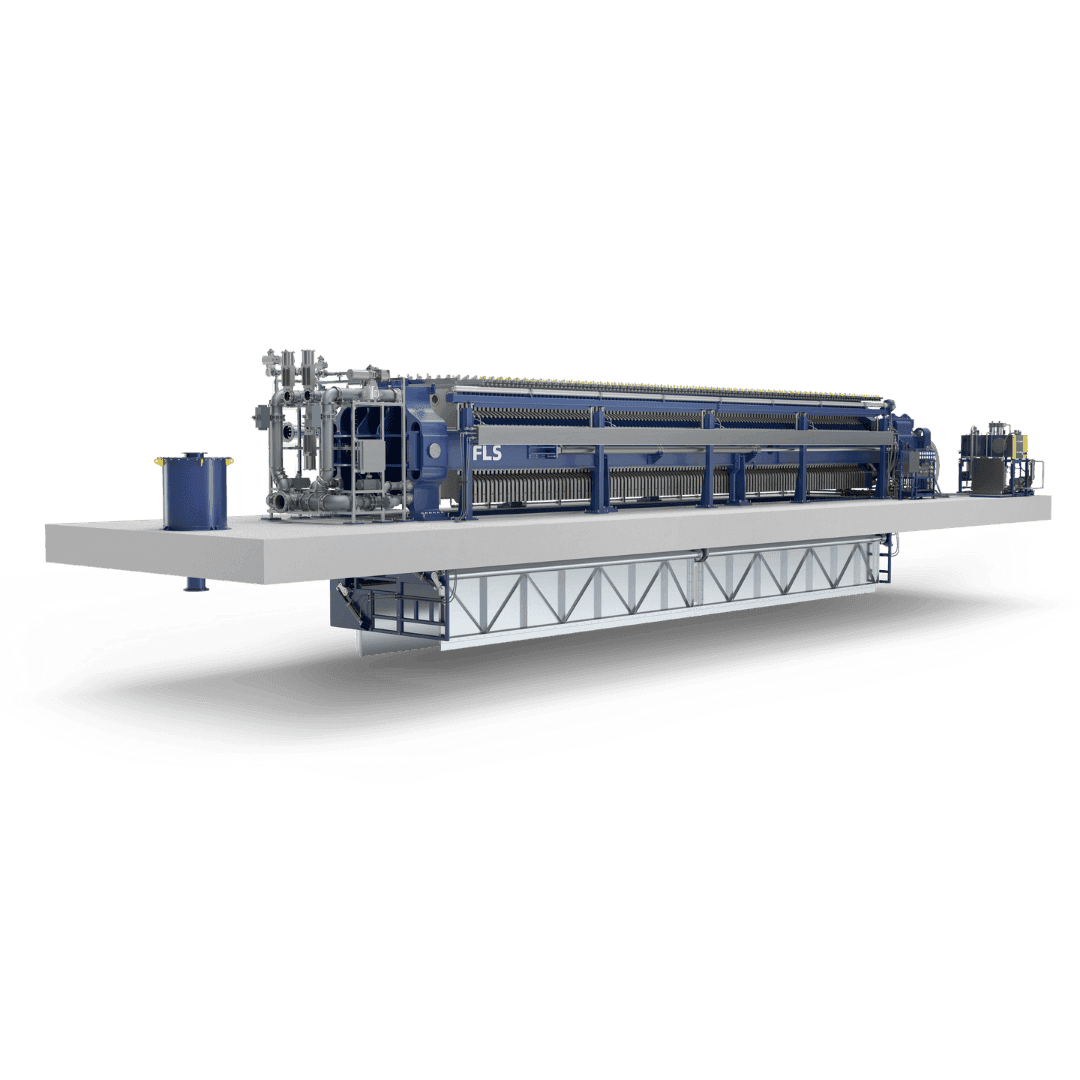

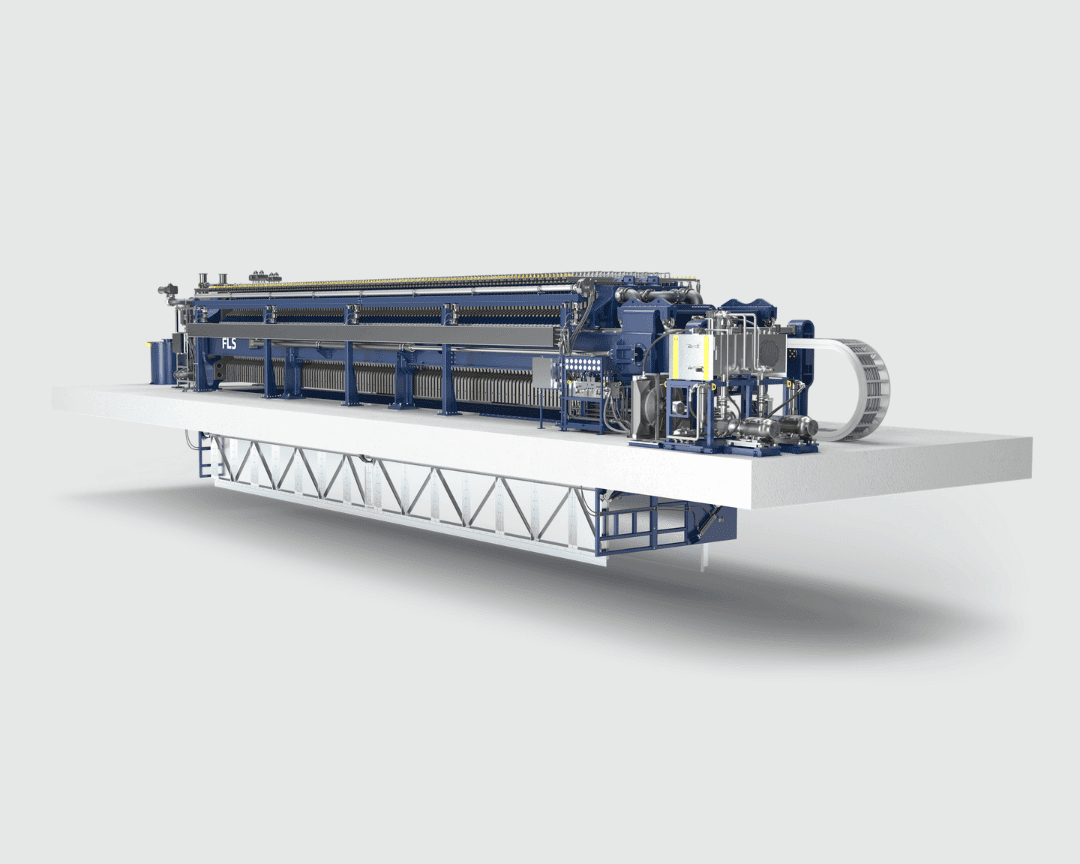

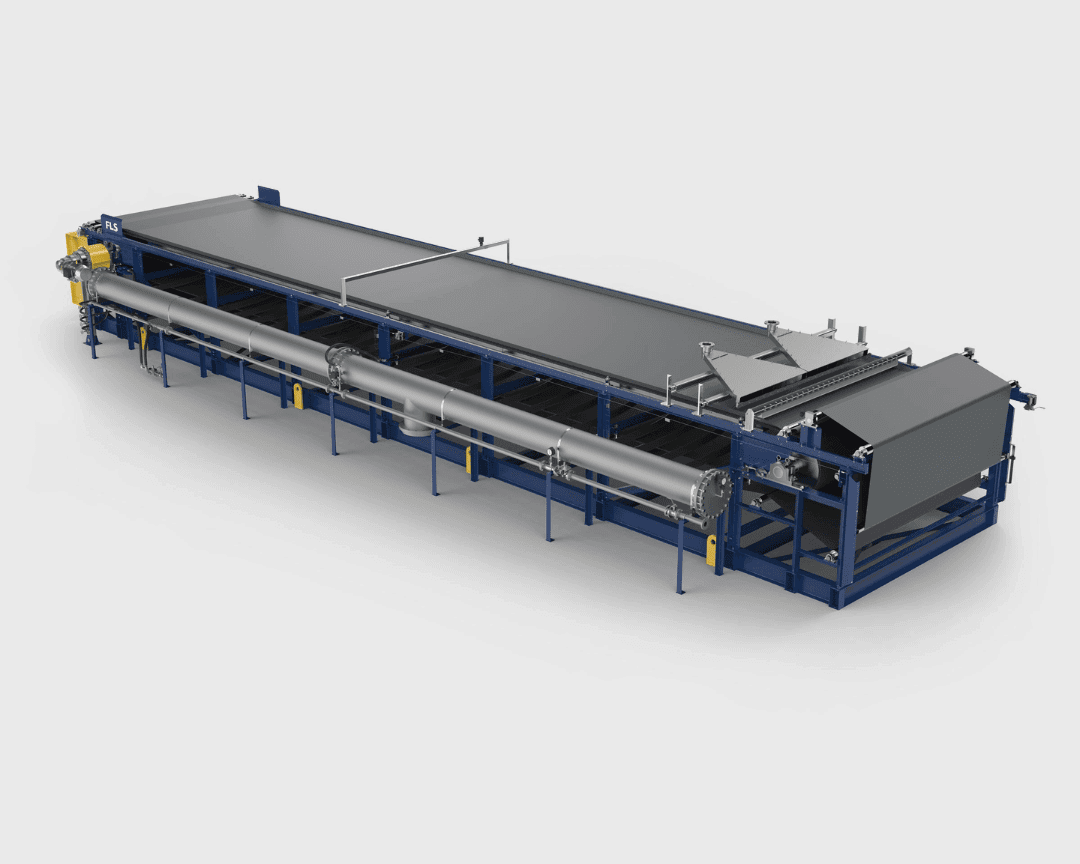

Get an FLS Vacuum Drum Filter tailored to your operation to kick productivity into high gear. We supply many special drum filter designs for unique use cases in many industries.

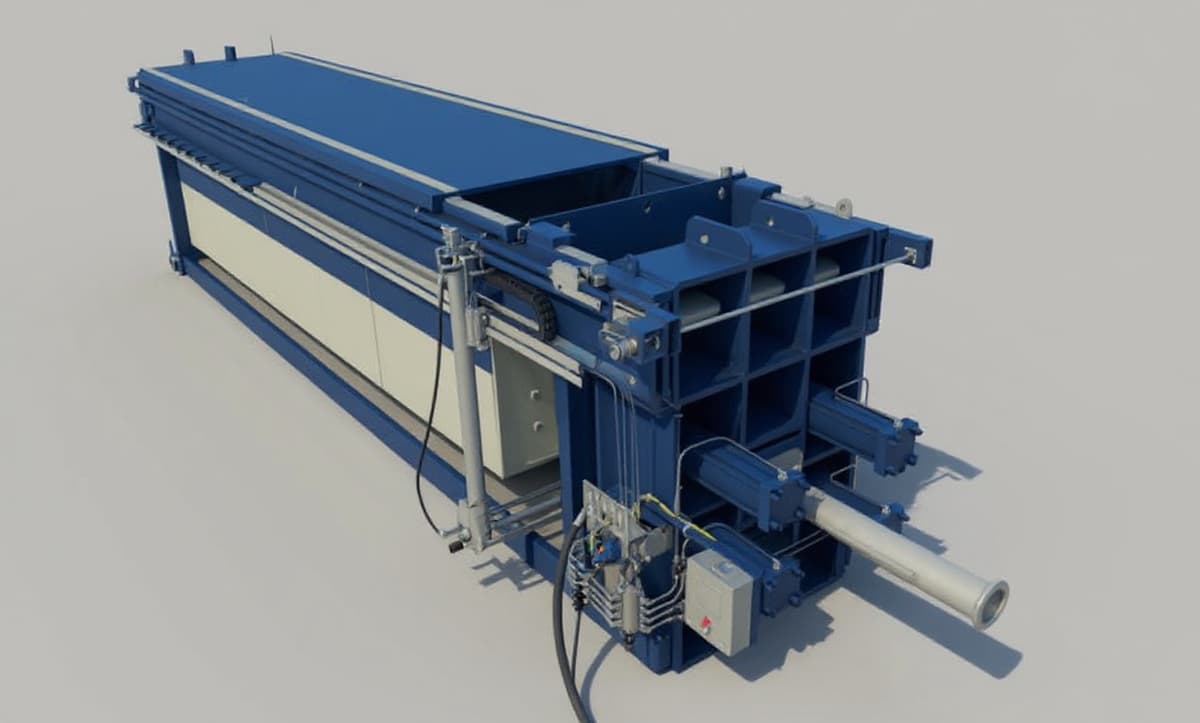

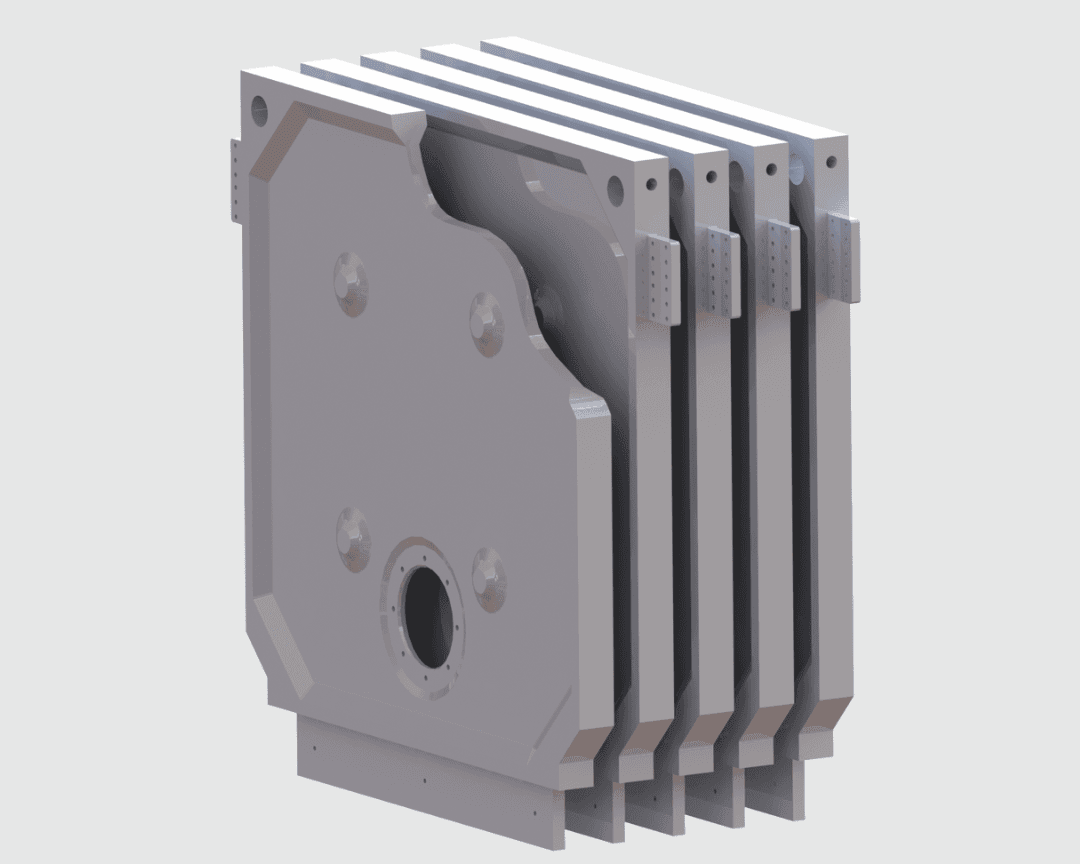

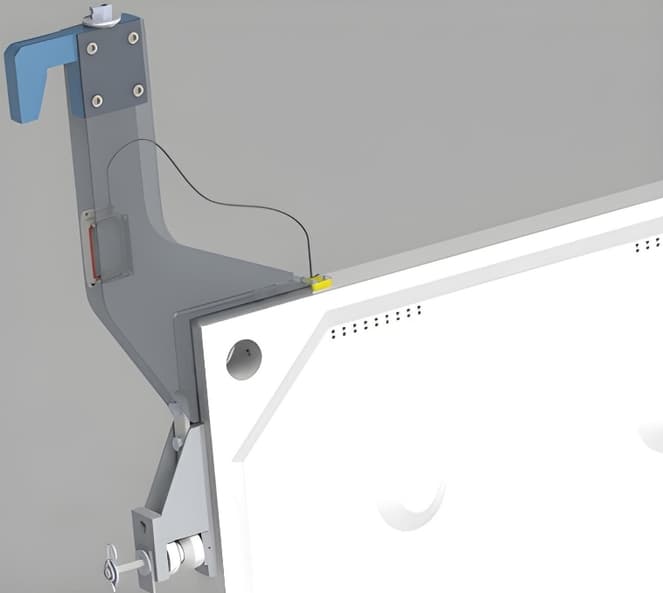

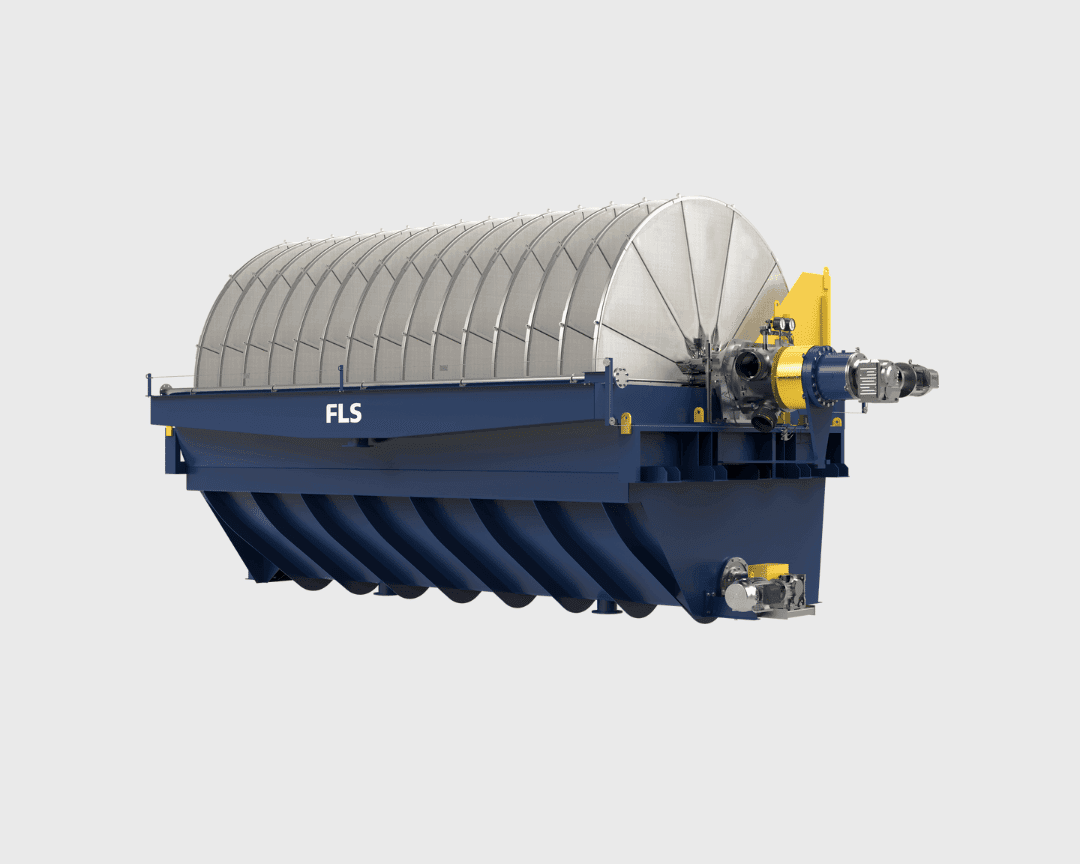

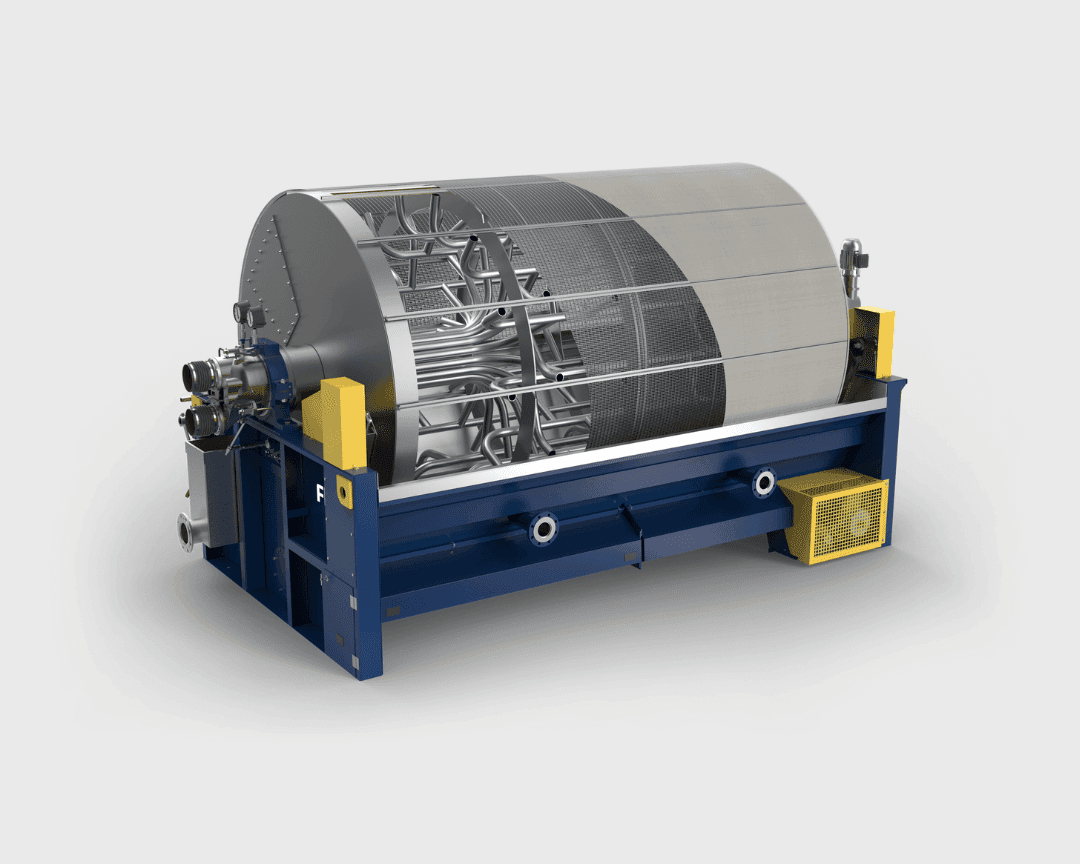

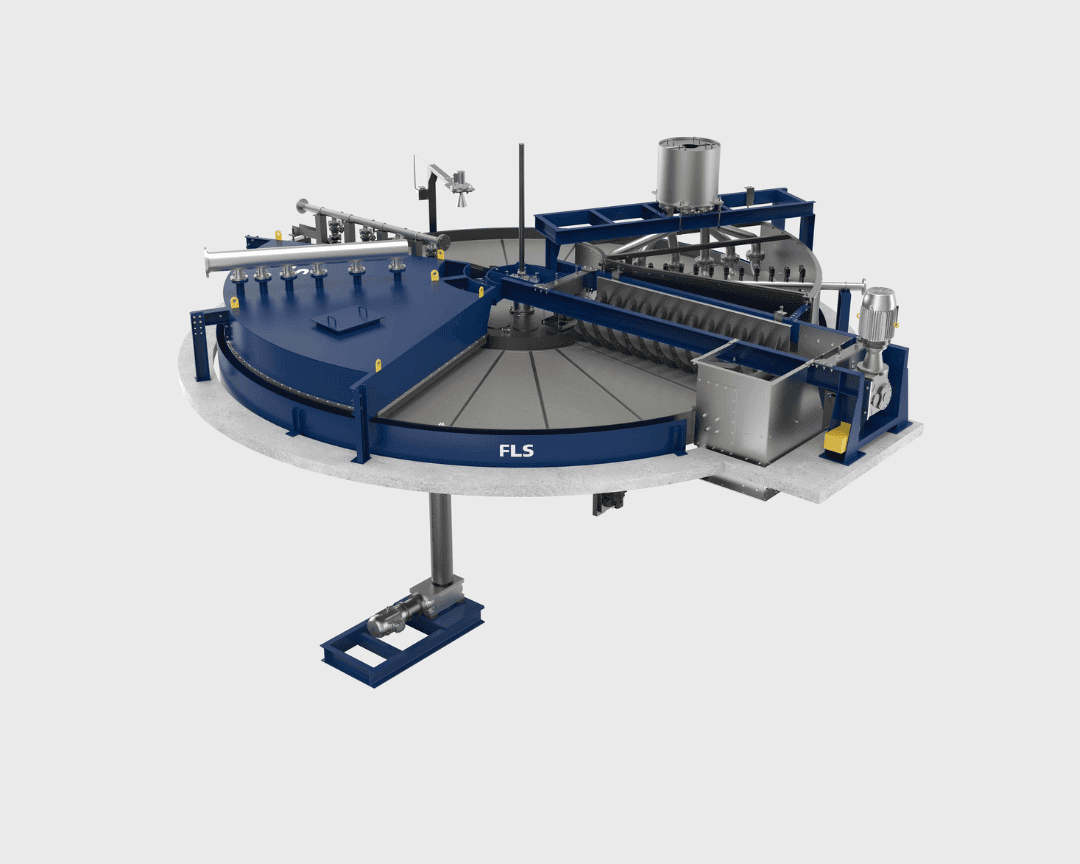

The drum filter’s basic operating principle is easy. Everything happens during one revolution of the drum: filter cake forming, cake drying, filtrate discharge and cake discharge. The filtration area on the drum surface is divided into separate cells, connected by individual pipes to a vacuum system.

The drum can be operated at various speeds to control cake thickness. The time available for the various filtration steps (cake filtration, washing, air drying) can be adjusted via the filter control valve. Slurry is continuously fed into the filter vat and an adjustable overflow weir controls the liquid level.

For efficient operation of the filter, the vat is equipped with an agitator to prevent solids from settling. Cake discharge takes place on the descending side of the drum.

The drum filter is easy to use and maintain and offers the following benefits:

- Low operation cost

- High capacity

- Superior flexibility

- Excellent filtrate clarity, with solids as low as 100 PPM

- Effective cake washing