Less waste, less downtime, less impact

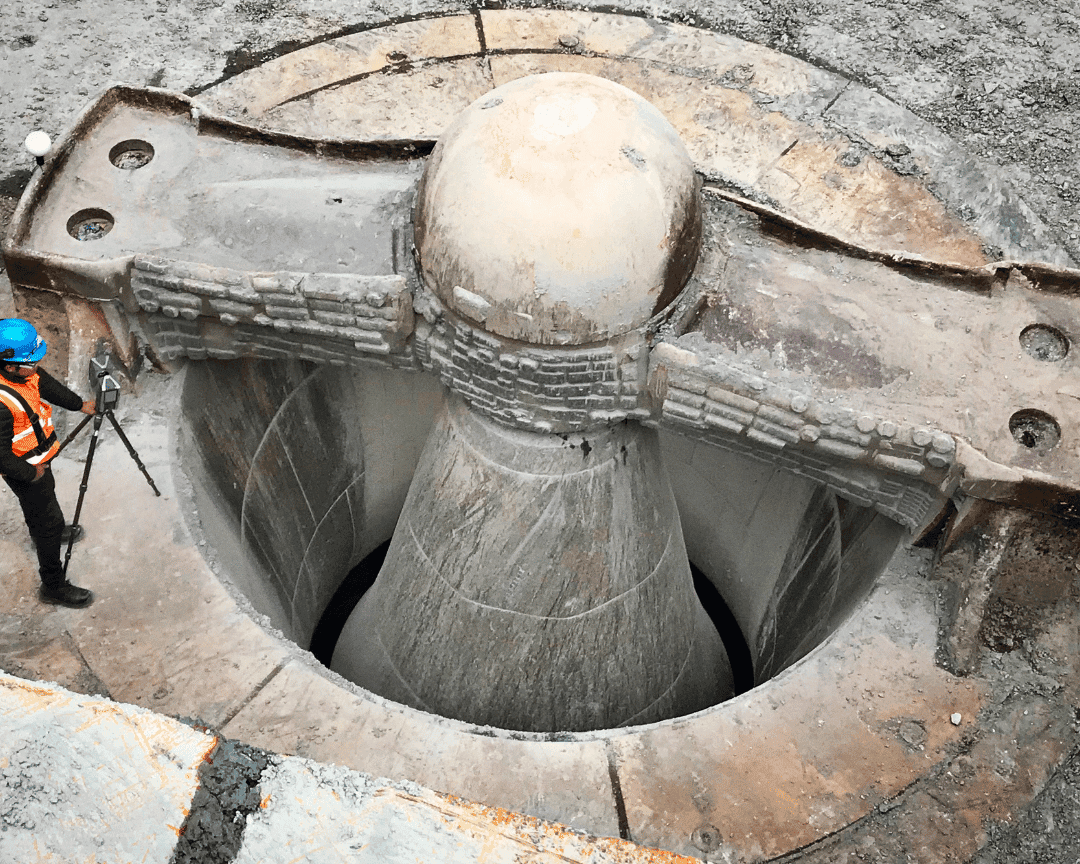

Choosing longer-lasting, better performing mining consumables not only supports your ambition to optimise overall crusher efficiency, but also creates a positive action for the environment. When wear parts last longer, the asset creates less waste and the consumption of new materials and the environmental burden of their manufacture is reduced.

Safer shutdowns

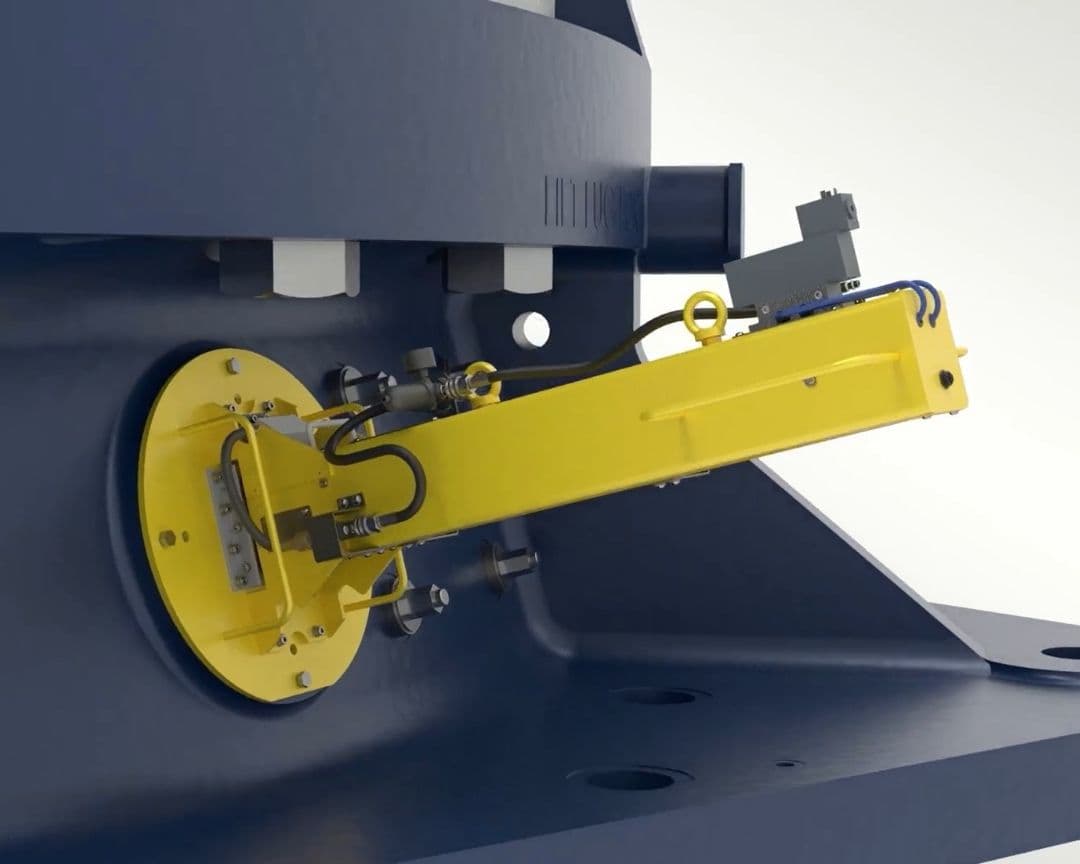

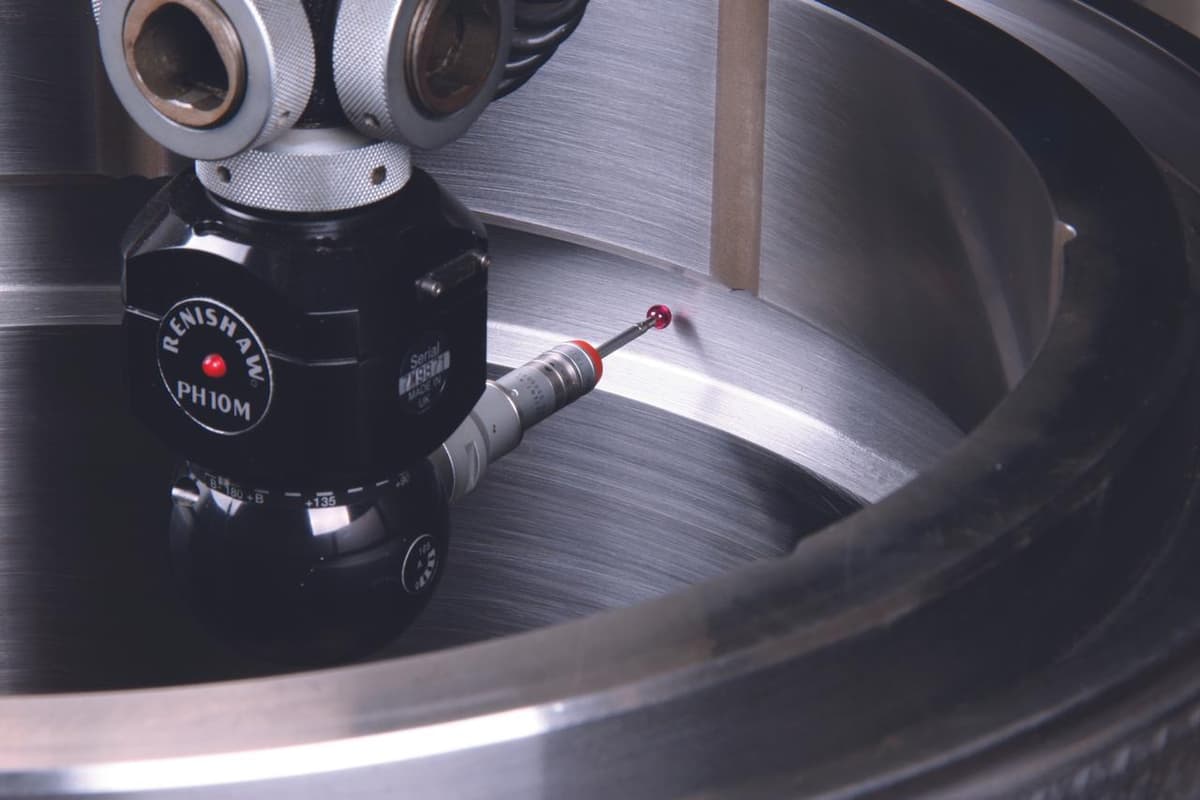

Safety is also an important consideration when choosing crusher wear parts. By extending wear life, downtime is reduced, and safety outcomes improve. Plus, specialist maintenance tools make it possible to perform maintenance without putting personnel into the crusher, reducing risk and enabling you to achieve up to 75% less downtime.