Flux mixers and furnace feeders

Available in a range of sizes, our flux mixers ensure thorough mixing of flux and dried concentrate, while our furnace feed conveyors deliver controlled feeding into the smelting furnace. Single and dual furnace feeding is available.

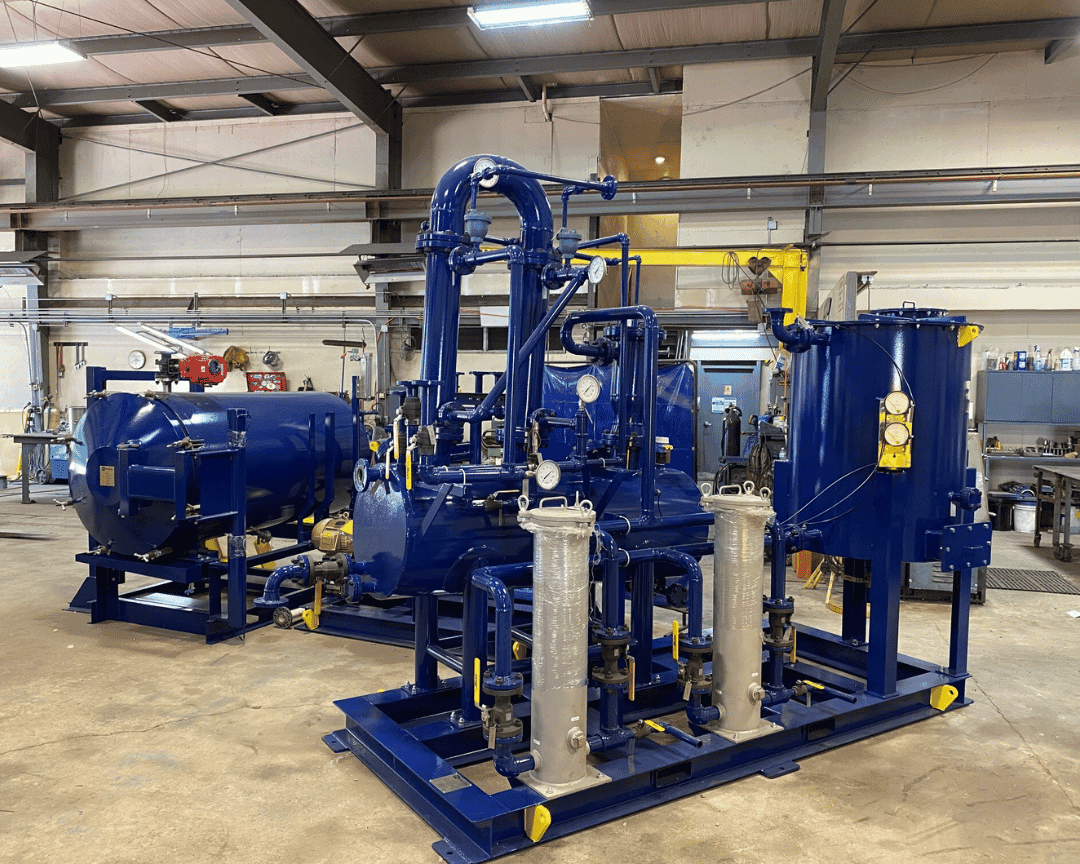

Air pollution control

We offer cartridge filters, baghouses, and wet scrubbers for particulate and gas removal, and mercury abatement systems for effective removal of mercury from smelt furnace stack gas and ventilation systems.

Slag handling and pouring equipment

We offer slag pots and carts, 3500 oz and 5000 oz silver moulds, 1000 oz gold moulds, mould stands, and slag crushing and separating equipment.