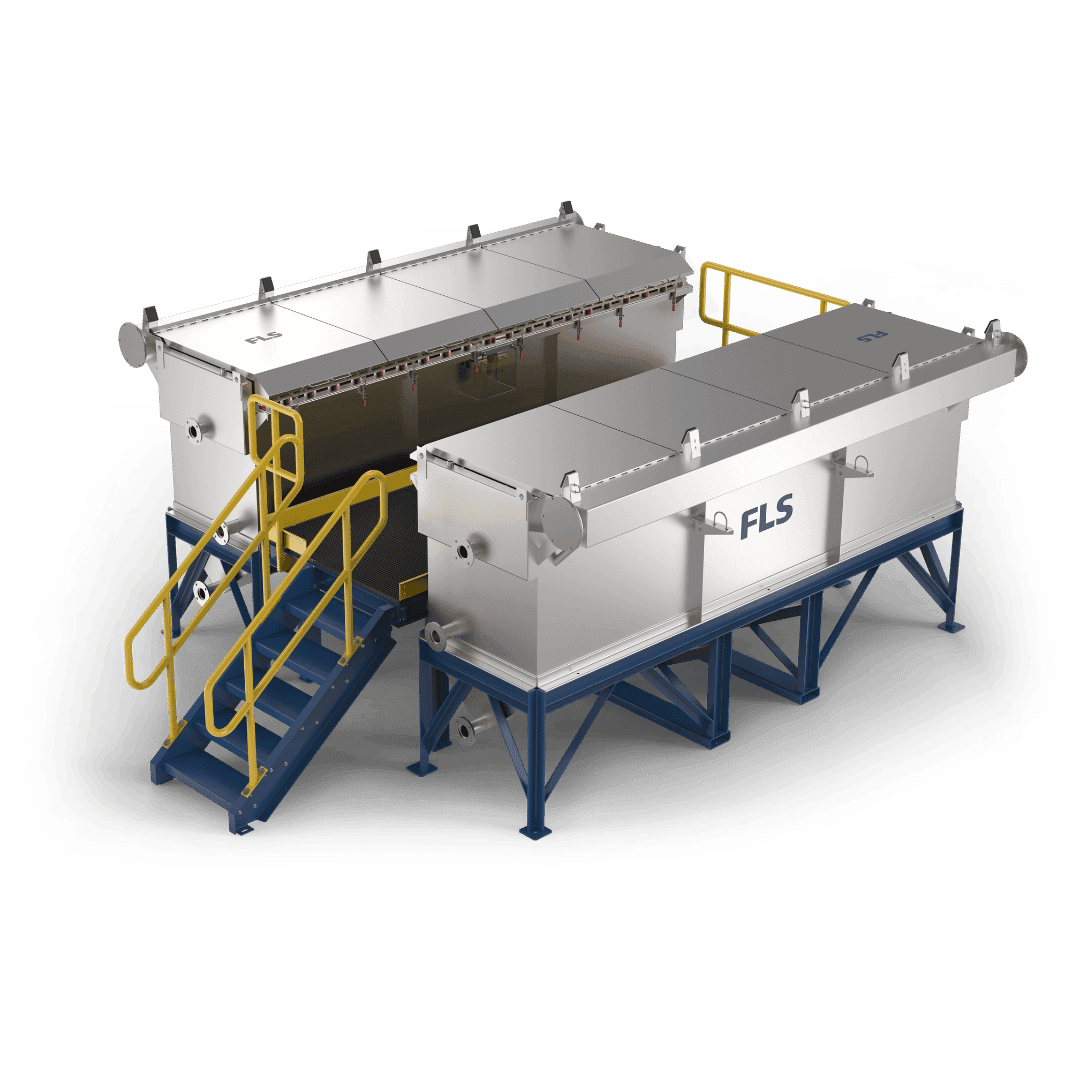

Our electrowinning cells

Treating 15-80 gallons per minute (3.5-18m3/hr) of pregnant solution, our electrowinning cells can be used with all types of metal recovery systems, including Zadra and AARL elution, high-grade leaching, and intensive cyanidation from gravity systems. They have also been used successfully with non-cyanide metal-bearing solutions. Cells are typically serviced once per week to recover the precious metal sludge and operate in the 2.1V to 5V buss bar range with 60A to 90A per cathode, although some high-grade solutions will use higher amperage per cathode.