What is REFLUX technology?

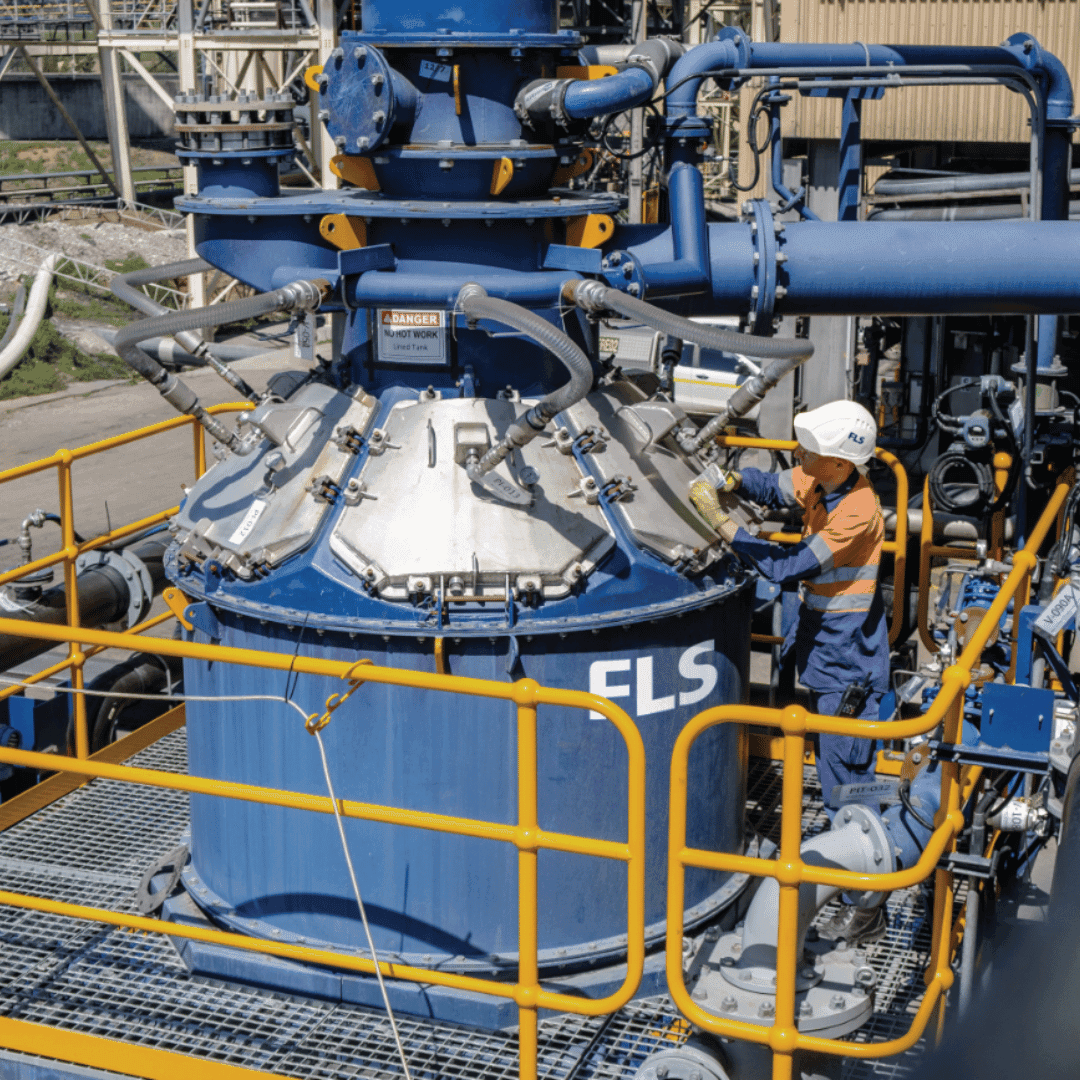

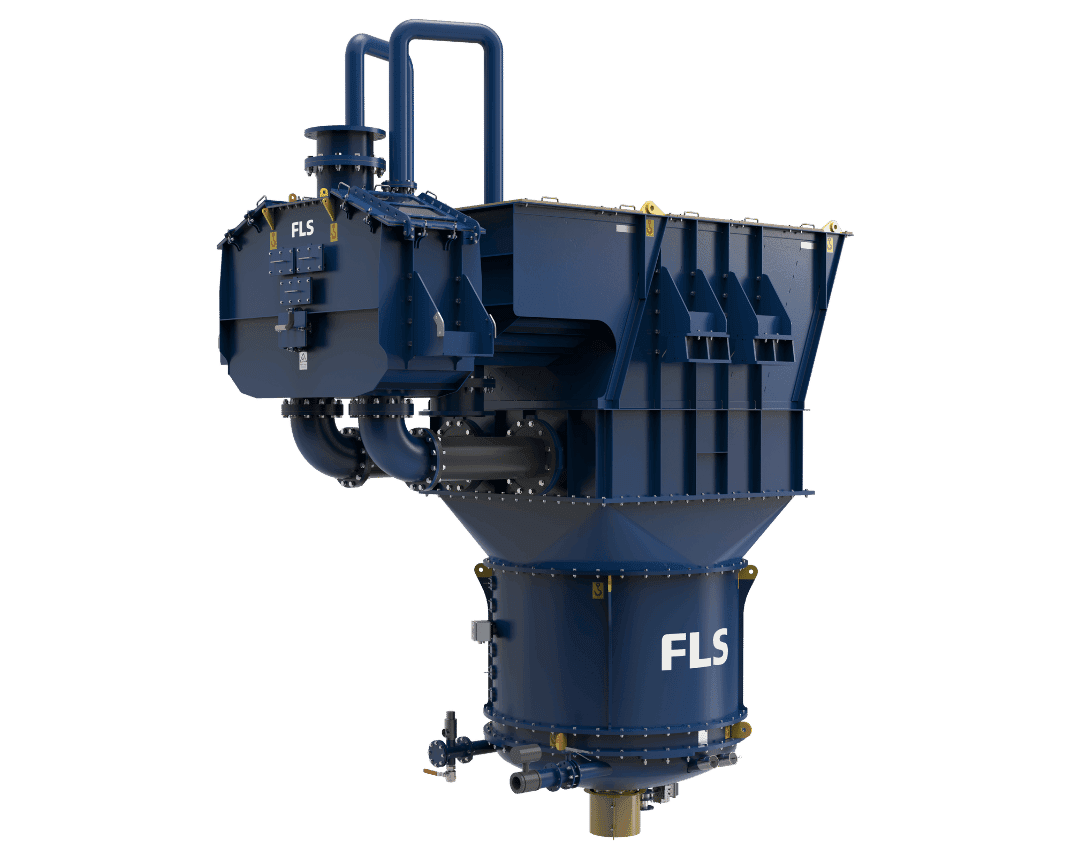

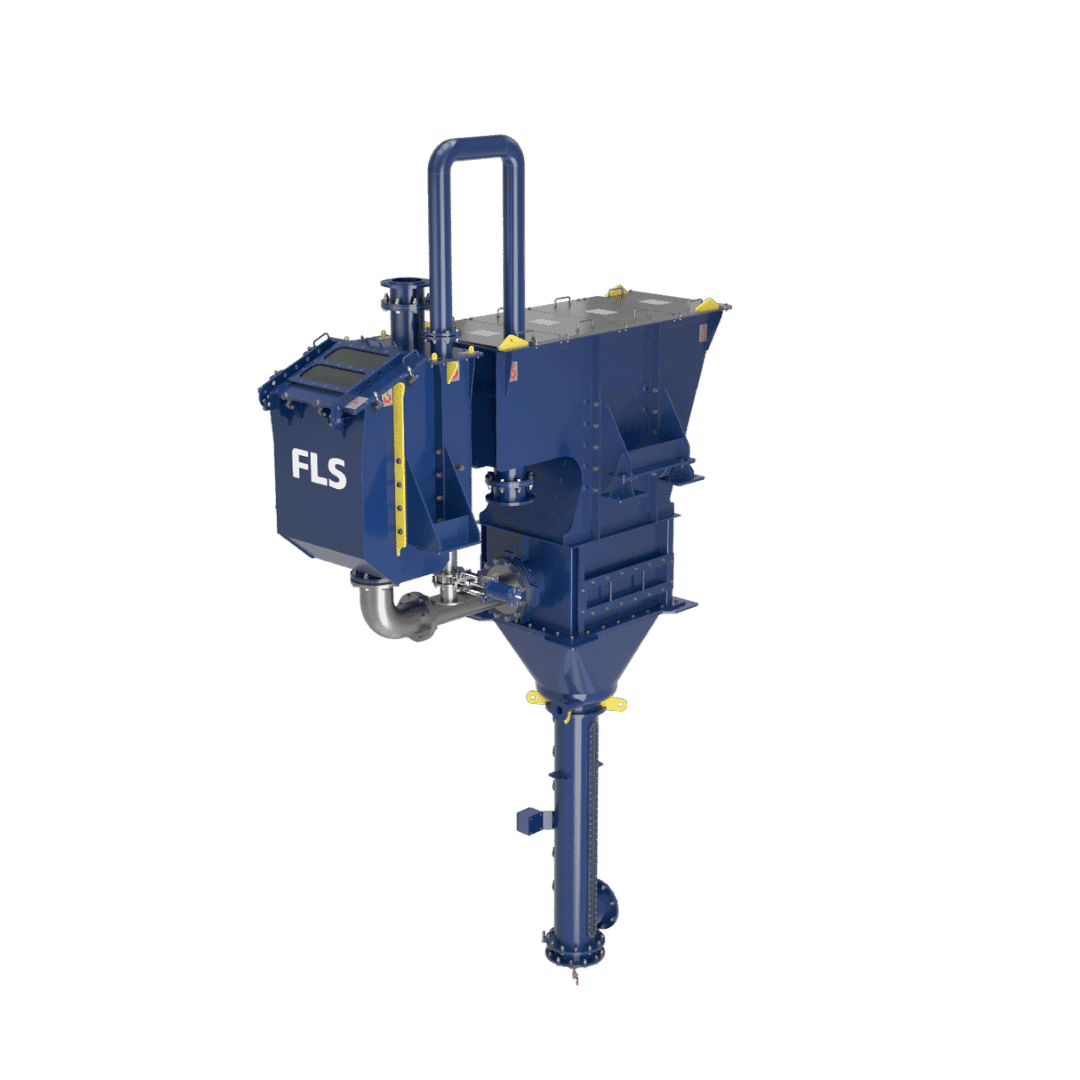

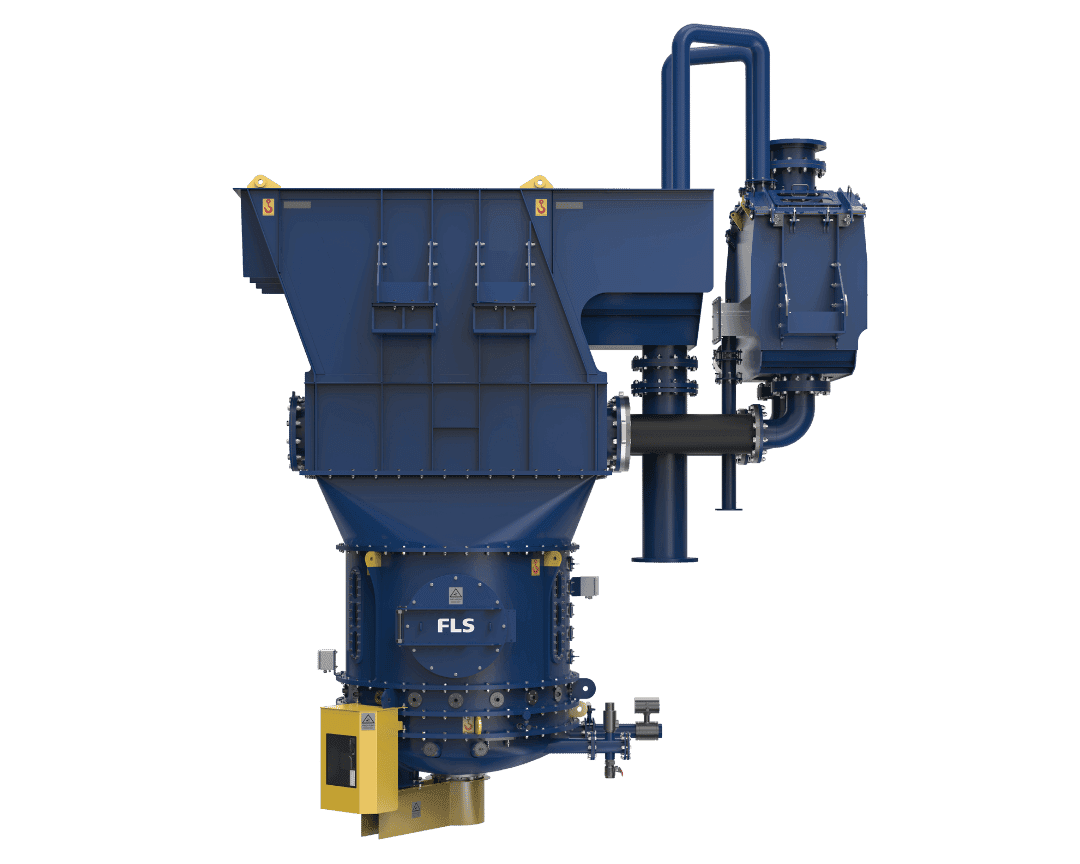

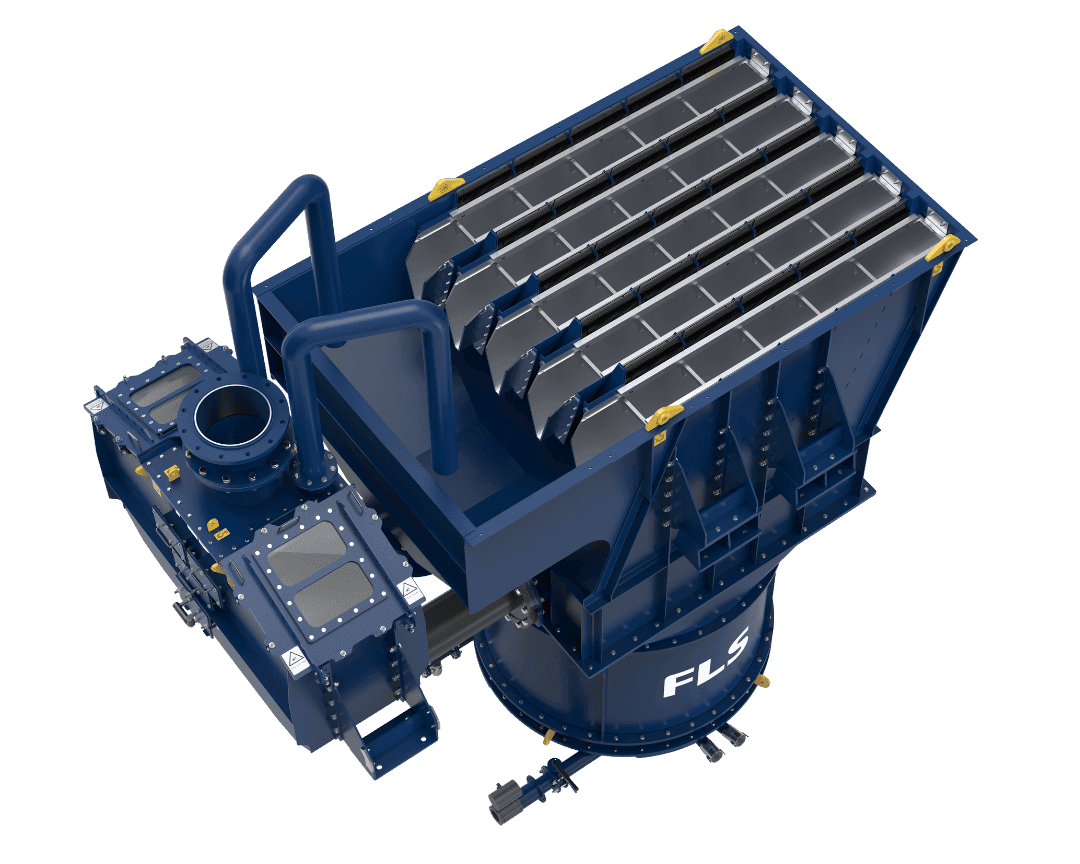

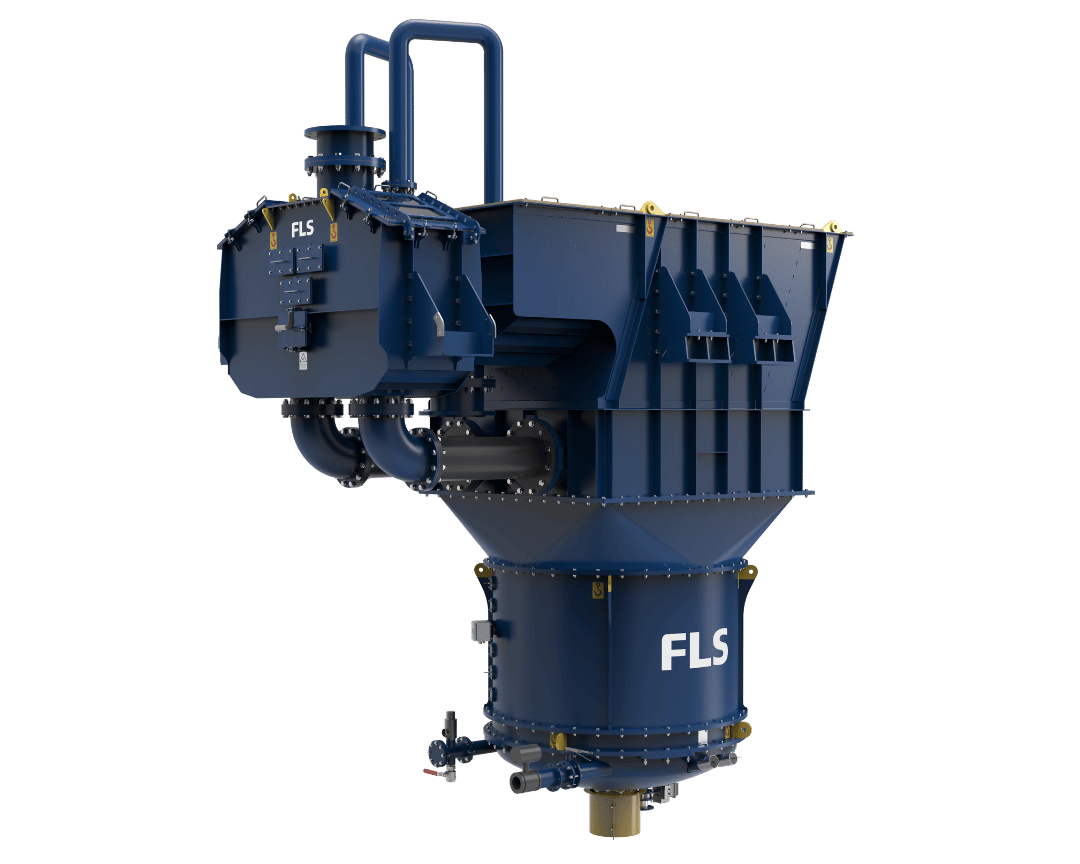

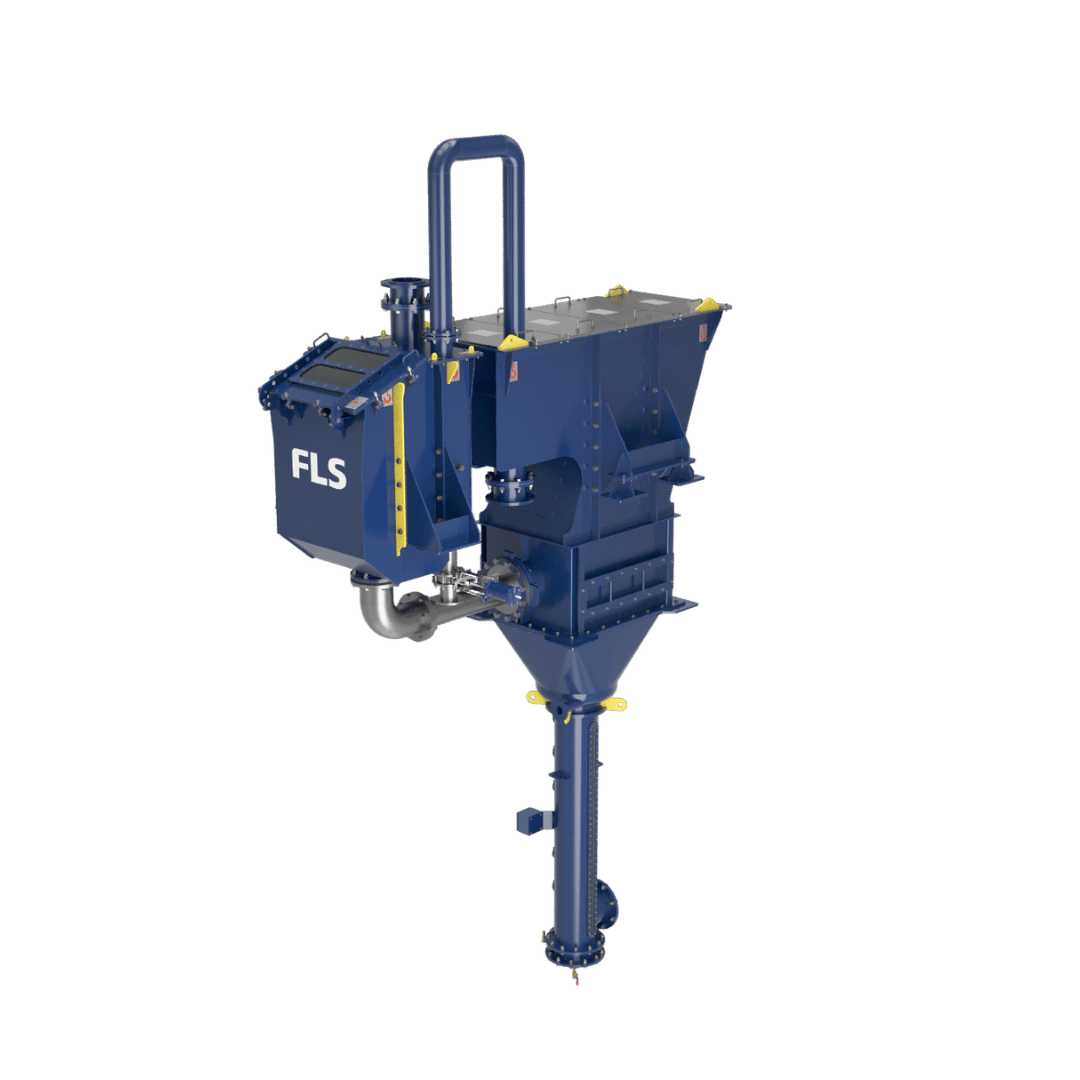

REFLUX technology was pioneered by Prof. Kevin Galvin from the University of Newcastle, Australia, focusing on gravity separation techniques for fine particle recovery. The first major application of the concept was the REFLUX Classifier (RC™), which combines inclined lamella plates with a fluidized bed to create an efficient, compact system capable of handling a wide range of particle sizes and densities. The REFLUX concept has since been incorporated into several other innovative products, such as the REFLUX Flotation Cell (RFC™), the GradePro™ Classifier, the Graviton™ Separator, and the coarseAIR™ coarse particle flotation solution.

The REFLUX concept combines a conventional fluidised bed separate with parallel inclined plates forming lamella channels. The fluidised bed helps to maintain particle mobility and acts as a semi-permeable layer, preventing the loss of valuable ore particles and allowing precise particle separation based on differences in particle density or size. The inclined lamella plates promote laminar flow, accelerating the settling process and reducing turbulence, improving overall separation efficiency.