Our offering

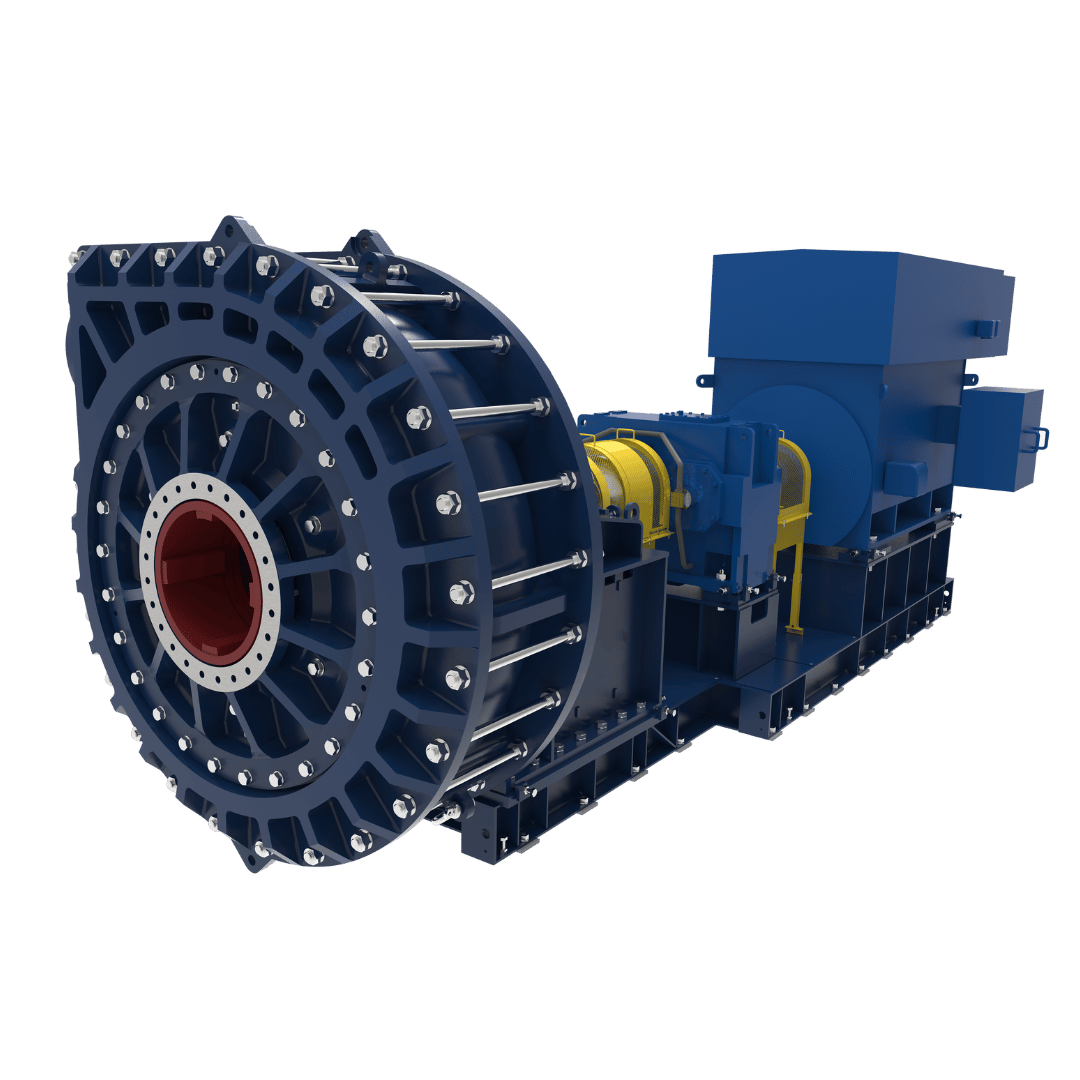

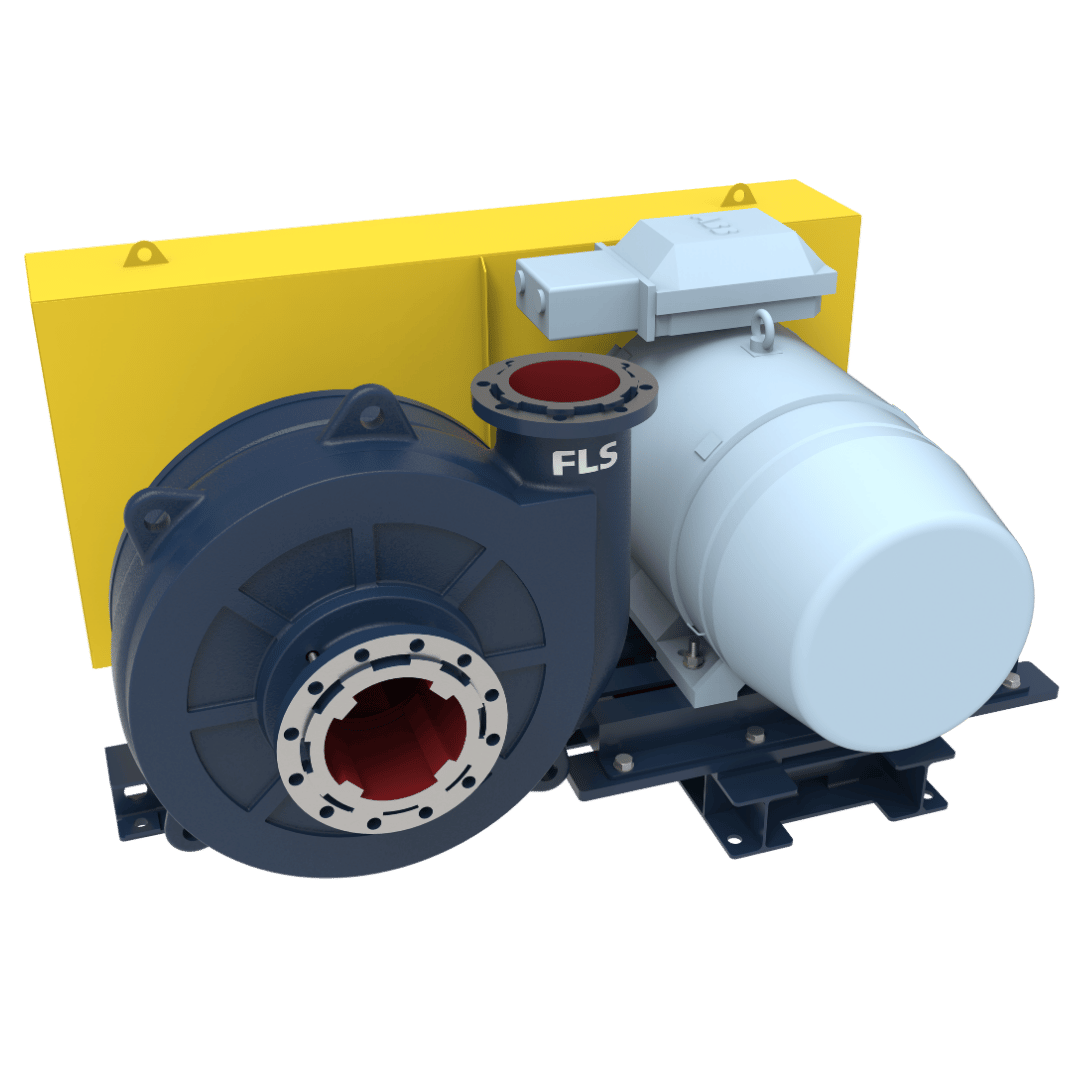

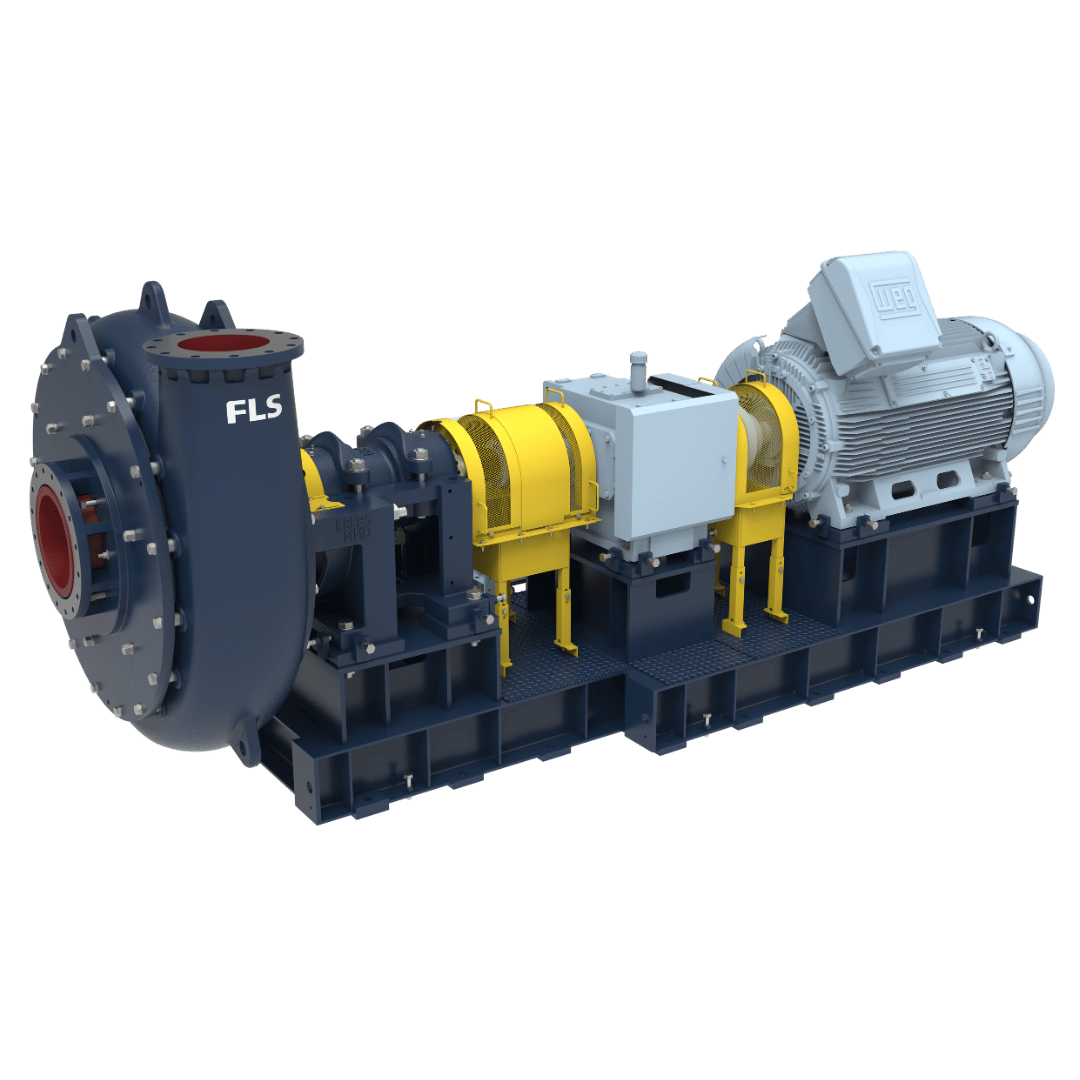

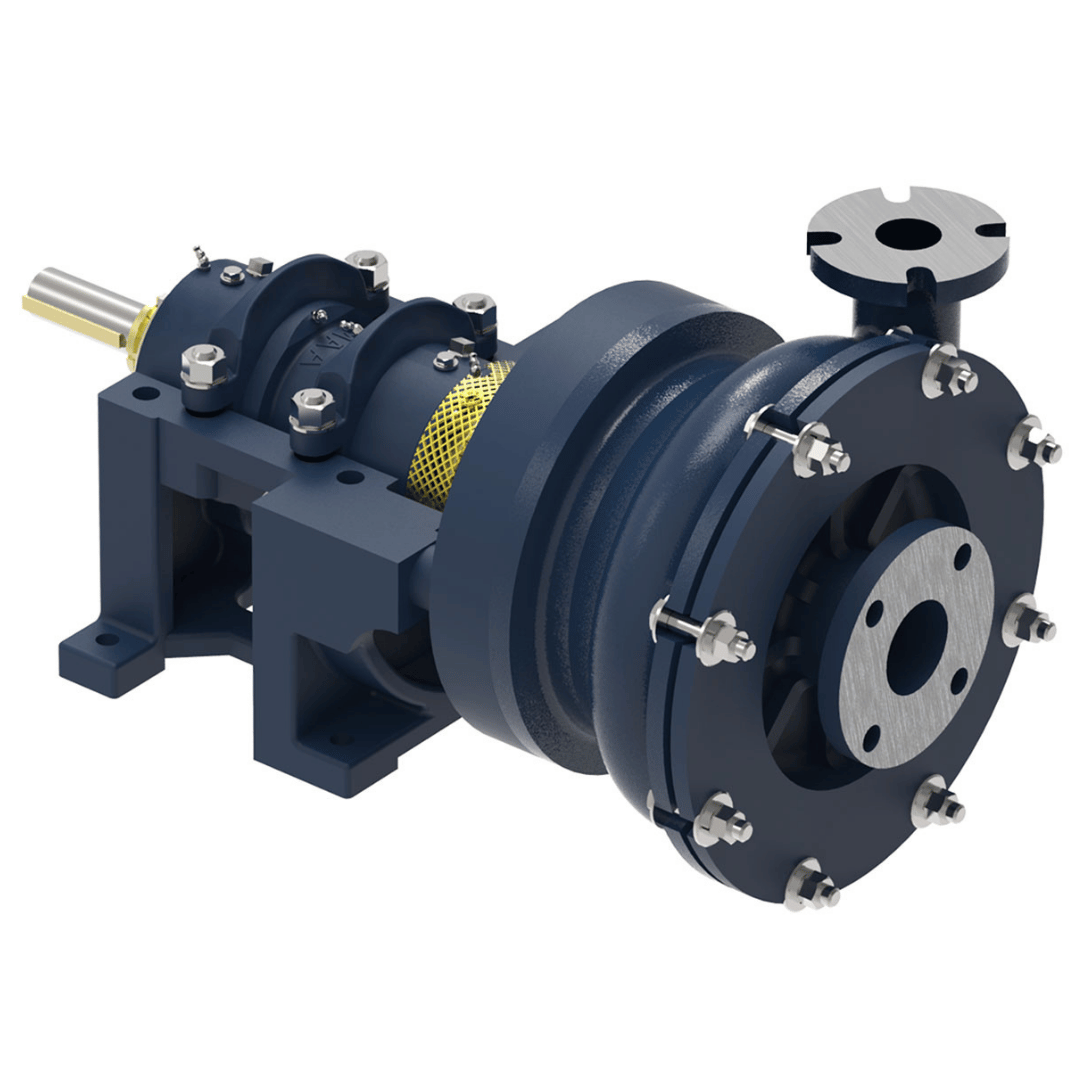

Explore our slurry pumping solutions

Services

Total lifecycle support for your slurry pumps

We don't just build pumps. We are with you for every step of your pump journey. From initial pump selection through installation, commissioning, and beyond. Our network of aftermarket service and spare parts centres ensures timely access to spare and wear parts, and fast offsite rebuilds. Expert site service engineers monitor pump performance over time, recommending upgrades or updates to operating practices to maintain BEP as process conditions develop over time. We also offer operation and maintenance training, including how to adjust the wear ring.

Frequently asked questions

FAQs for slurry pumping systems