Safely handle the highest of operating pressures

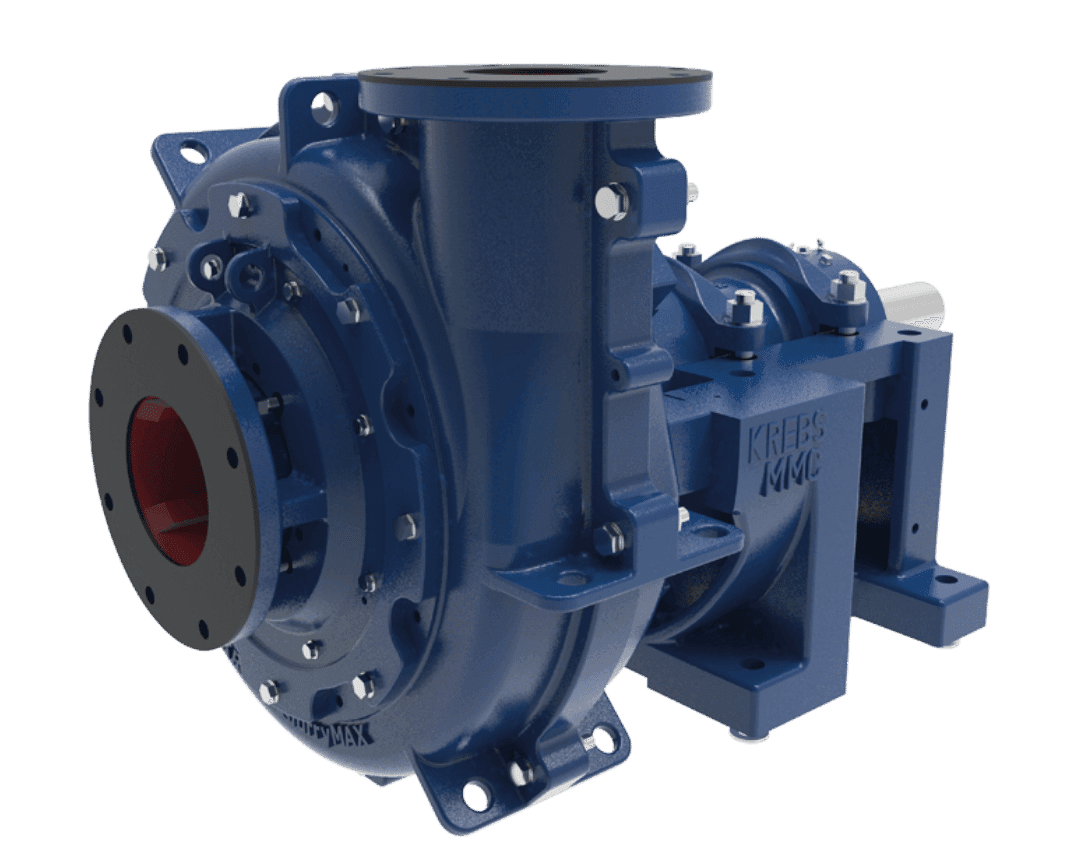

Our millMAX and UMD high-pressure pumps feature the same internal hydraulic design as standard-pressure pumps but allow for higher operating pressures.

Our millMAX and UMD high-pressure pumps feature the same internal hydraulic design as standard-pressure pumps but allow for higher operating pressures.

Full-face adjustment is nearly impossible in high-pressure applications. Our proprietary wear ring solves this. Easily adjusted by a single operator with a standard wrench, it allows control of suction-side clearance, maintaining hydraulic performance over the life of the pump at constant RPM. This results in higher efficiencies and extended component wear life.

The tie-bolt design of millMAX and UMD high-pressure pumps allows operators to take ultrasonic casing thickness measurements around the pump, helping predict and schedule maintenance shutdowns before failures occur. Meanwhile, slurryMAX-HP pumps feature a split-case design that facilitates maintenance access to internal parts.

Our millMAX-HH/XHH product range is designed for high total dynamic head. Suitable for filter press feed and one- or two-stage pumping systems with high heads, millMAX-HH pumps feature a concentric casing, enabling them to operate at even velocity and pressure around the casing, regardless of where the pump is to its BEP.

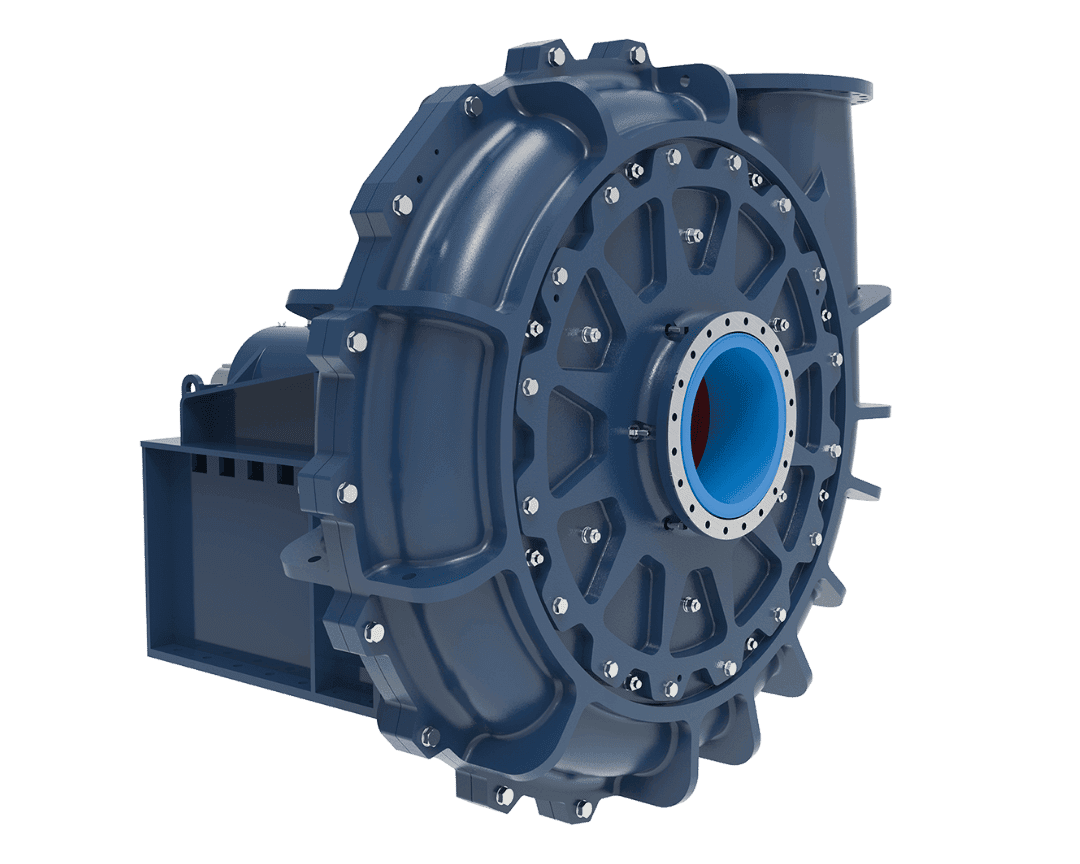

Able to handle operating pressures of >500 psi (35 bar), millMAX-HP pumps bring the benefits of our celebrated millMAX slurry pumps to high-pressure, multi-stage applications. With the same superior internal hydraulic efficiency as standard-pressure models, they feature a more robust casing and wear linings suitable for high-pressure conditions.

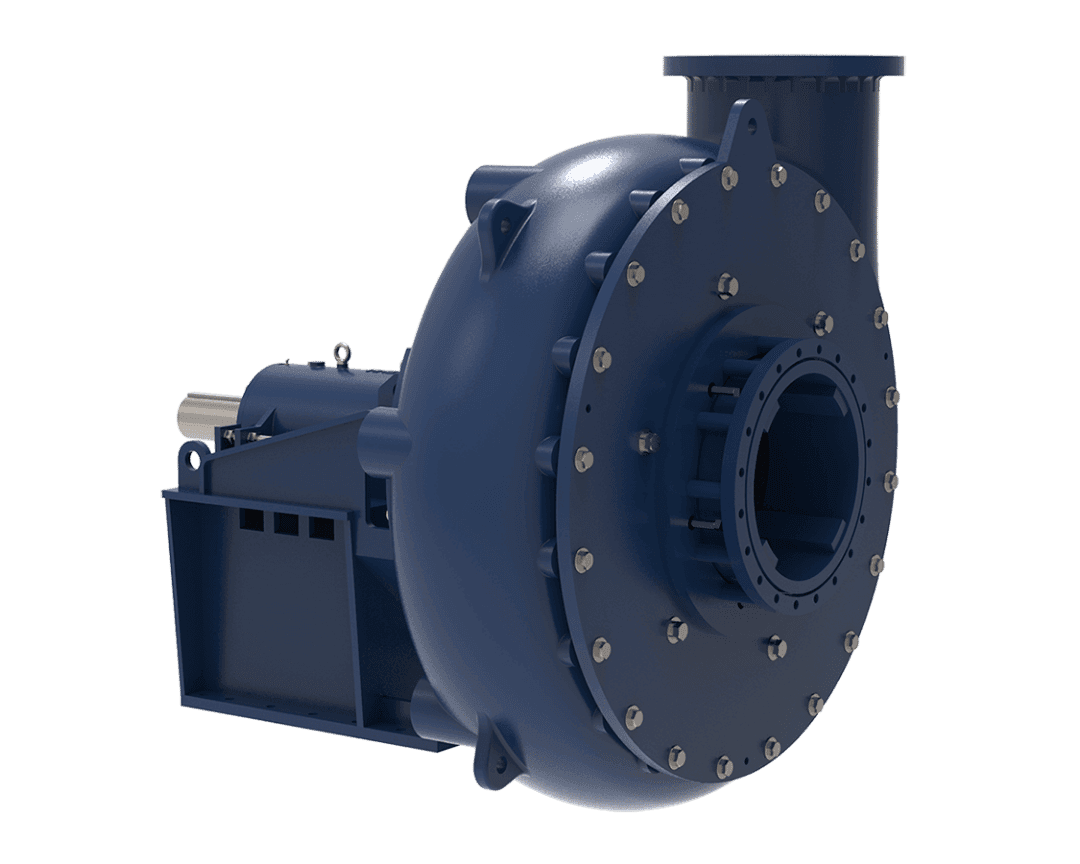

The slurryMAX-HP/XHP product range offers high-pressure models of our slurryMAX-XD split-case slurry pump. Ideal for multi-stage, high-pressure systems, the pumps feature a high-pressure outer casing with added rib reinforcement, thick elastomer liners, and a heavy-duty impeller for extended wear life.

Designed for multi-stage, high-pressure coarse tailings and hydro-transport applications, UMD-HP pumps create a deep slurry bed that shields the casing from the direct impact of coarse solids, an enlarged cutwater clearance to reduce turbulence, optimised impeller design to reduce local wear, and oversized outer liners to protect the casing sides.

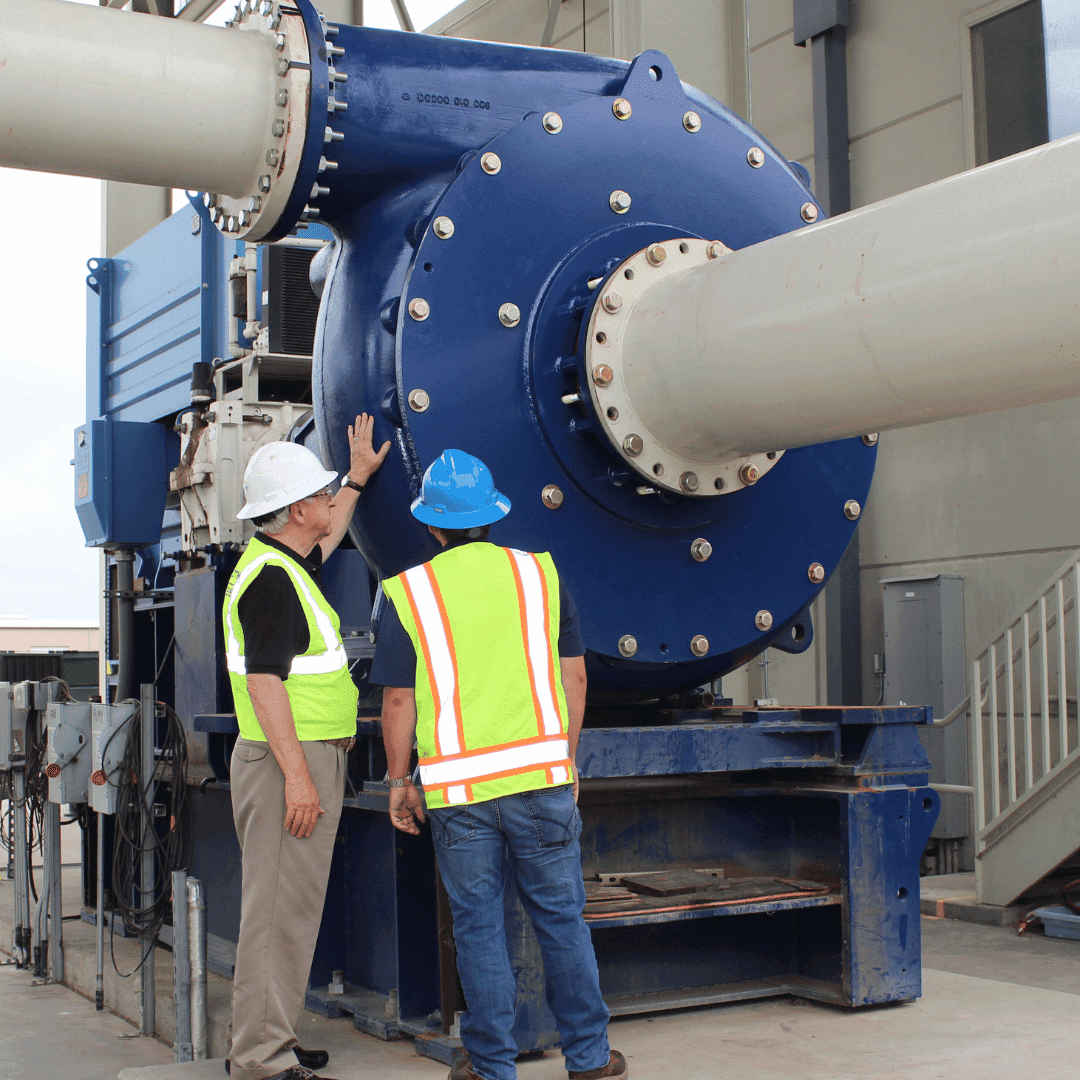

We provide comprehensive lifecycle support services for your KREBS slurry pumps. Our global network of service and spare parts centres ensures prompt access to parts and consumables, as well as offsite rebuilds through our pump rebuild exchange program. Our onsite service engineers monitor pump performance, offering recommendations for upgrades or adjustments to operating practices to maintain optimal efficiency as process conditions evolve over time. Additionally, we offer operation and maintenance training, including guidance on adjusting the wear ring.