Fine Coal Centrifuges

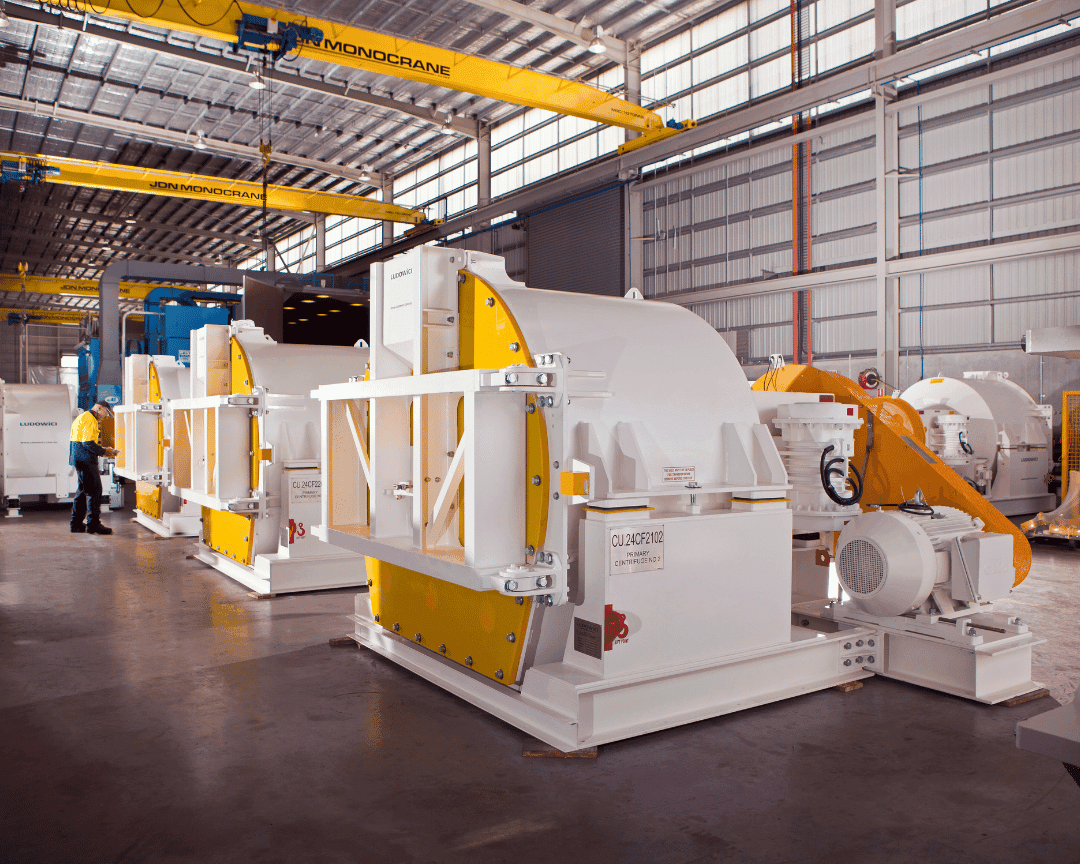

Built with strong material to cope with the toughest mining conditions, our Fine Coal Centrifuges are built to last. Their exceptional wear life increases efficiency, reduces maintenance and replacement costs and produces high-quality dewatered coal in the most cost-effective way.

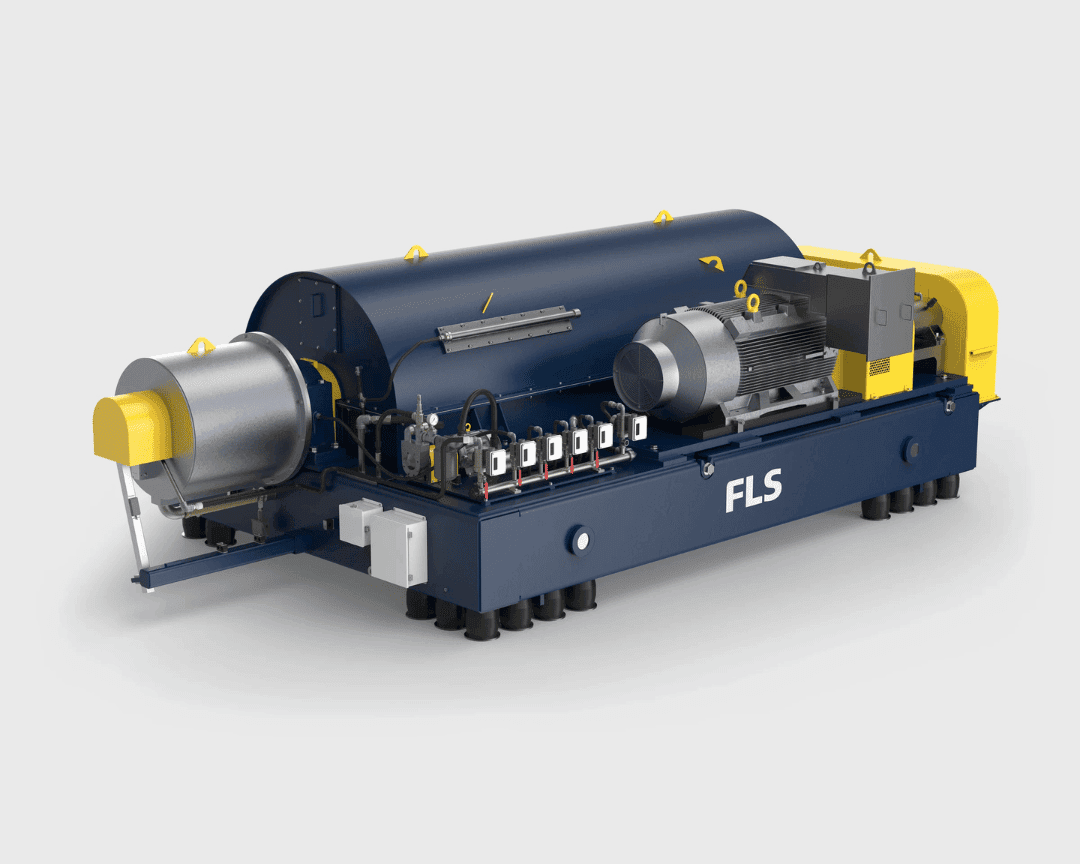

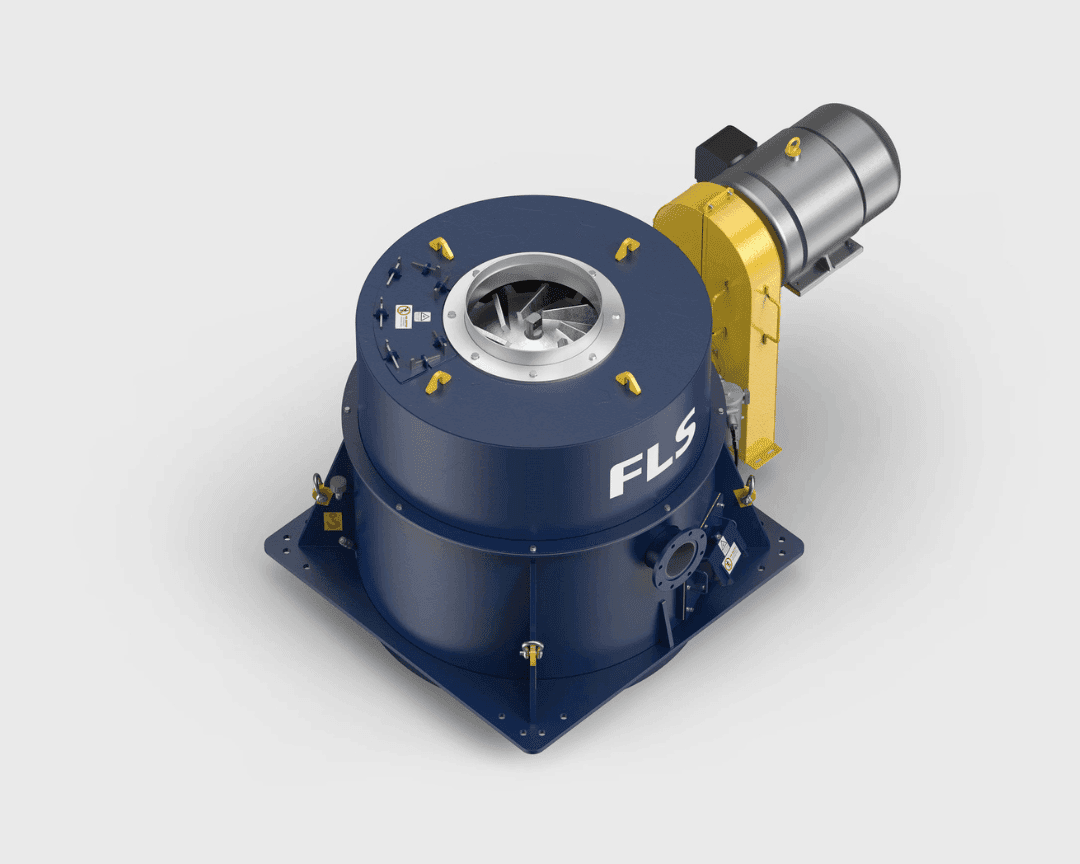

Our Fine Coal Centrifuge range includes both vertical and horizontal scrolled basket style machines that use centrifugal force to separate surface water from coal, salt, granulated slag and other chemicals. Benefits include:

- Durable construction for a long service life, including abrasion-resistant linings as standard

- Feed distributor and scraper scroll improve ease of operation and reduce wastage

- Simple maintenance design enables disassembly in order of component wear

- High efficiency, high capacity – up to 100 tph through the HFC1300 S2, which achieves the driest possible product

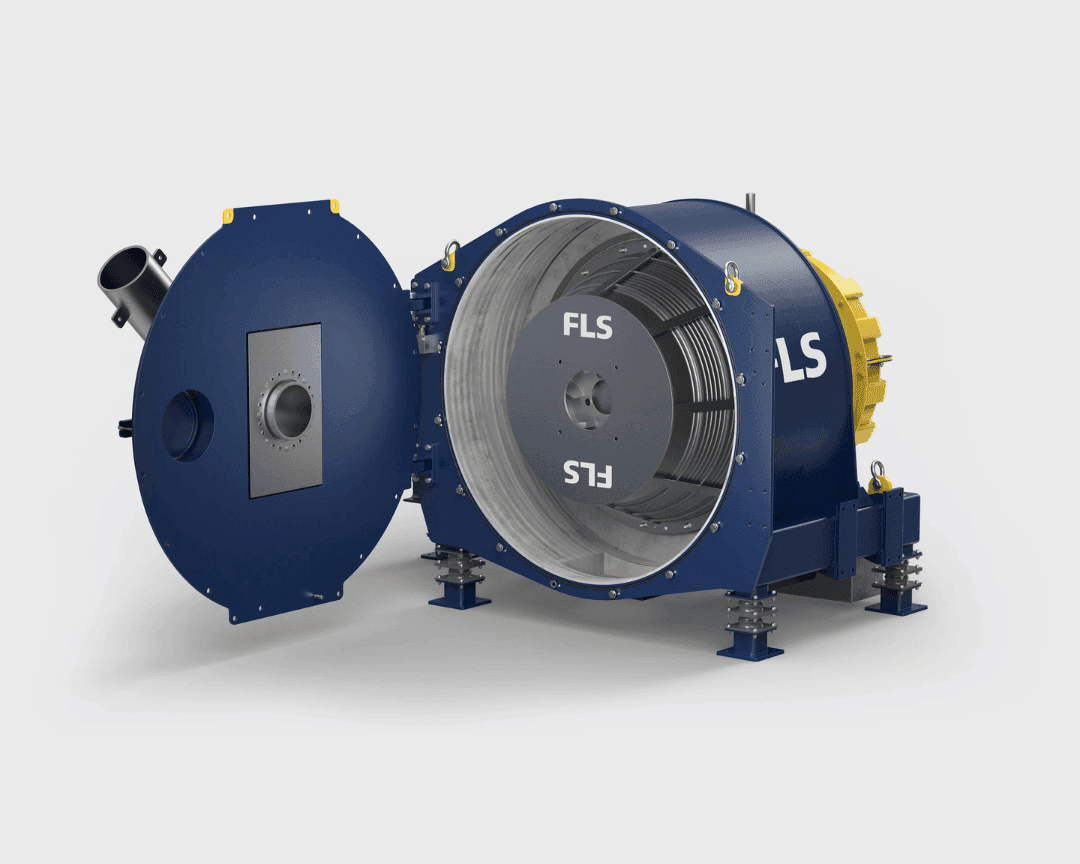

- Full customisation of baskets, drive arrangement and drive motor positions

- Efficient dewatering, plus low installation and running costs

Both the FC1200 and HFC1300-S2 centrifuges are designed to process feed slurry through a rotating, perforated basket. As the basket rotates, its G-forces push the slurry against the surface, allowing water to filter through the solids and discharge through the machine's pipes. The scroll, featuring a screw flight design, moves the solids through the basket until they are discharged as dry product. These centrifuges are versatile, capable of accepting feed slurry from various sources, such as thickening cyclone underflow, sieve bend overflow, or fines dewatering screen overflow. They are highly effective at reducing feed moisture from 45–55% to as low as 9–13%, depending on particle size distribution. While the FC1200 emphasizes ease of maintenance and high throughput, the HFC1300-S2 stands out for its high capacity, advanced real-time monitoring, and enhanced safety features, making it well-suited for demanding industrial applications.