How does coarseAIR coarse particle flotation work?

Prof. Kevin Galvin of the University of Newcastle, Australia, developed the technology in collaboration with FLS. It is based on the REFLUX Classifier® (RC™), a highly efficient fluidised bed separator widely adopted in the mining industry to improve fine particle recovery. The resulting coarseAIR solution combines the hydrodynamic advantages of the RC with the selectivity benefits of flotation to float larger particles than conventional flotation processes, which are typically limited to particles -200μm.

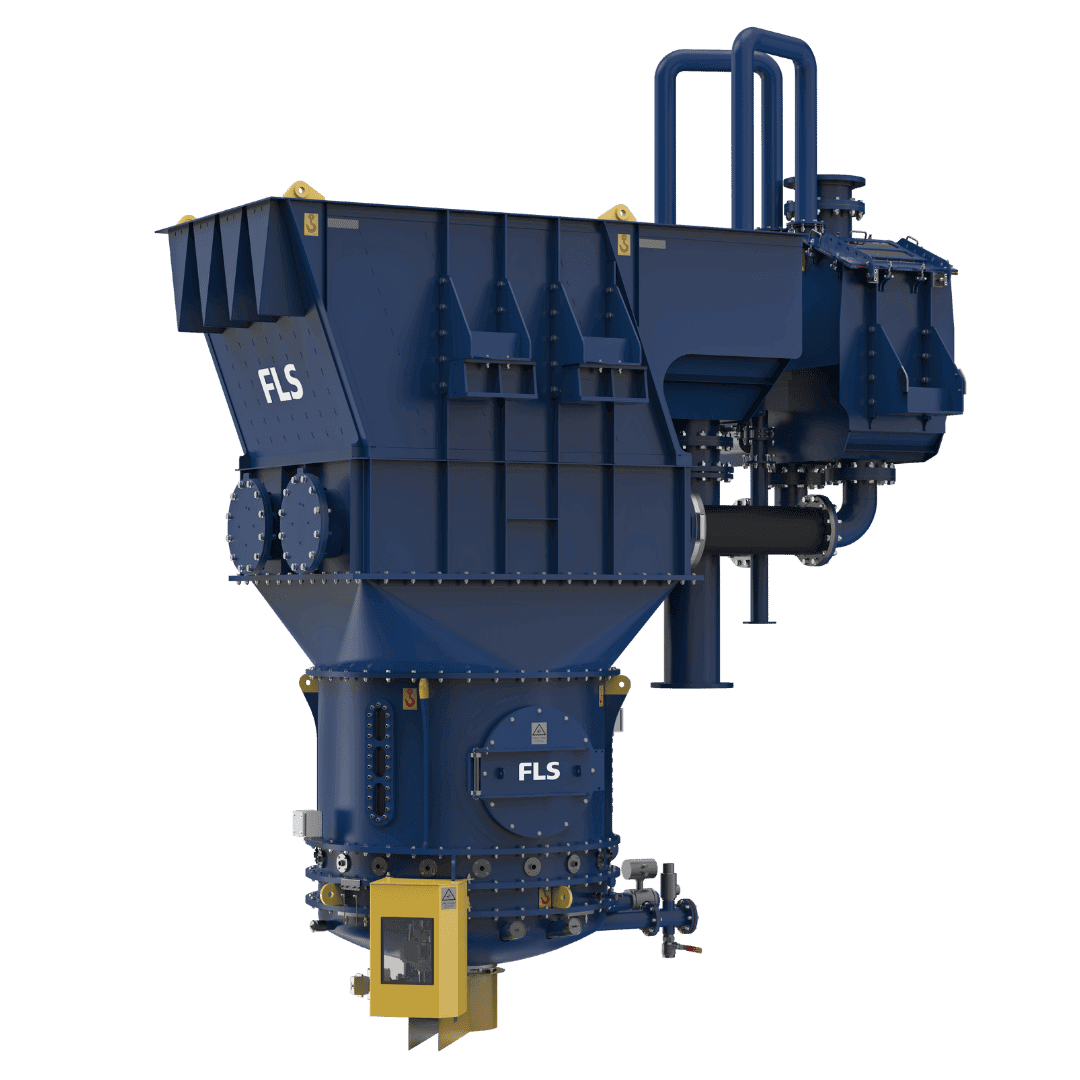

The coarseAIR cell operates as an aerated fluidised bed separator, where coarse particles are floated without the high levels of agitation seen in conventional cells. This helps to prevent bubble-particle detachment seen with coarse particles in traditional systems. At the same time, the fluidised bed acts as a semi-permeable layer, avoiding the loss of bubble-attached coarse particles to the underflow.

Above the fluidised bed, a series of inclined lamella plates enhance bubble-liquid segregation, allowing only bubble-attached particles to be carried up into the separation zone and the overflow. The lamella region also rejects any misplaced particles, as unattached particles carried hydraulically into the lamella region are rejected back to the separator, resulting in a high-grade coarse concentrate.