Explore our process automation solutions

Digital process automation reduces energy consumption

The mining industry is a significant power user, estimated to be responsible for up to 7% of the world’s power consumption. As our industry works towards achieving the MissionZero Mine, efficiency measures have a vital part to play in reducing energy consumption. Digital tools and services, such as LoadIQ – our mill load optimisation tool, which reduces energy consumption by up to 10% - will help mines make the changes needed to achieve these efficiency gains.

The benefits of process automation solutions from FLS

Process control

Our Process Control Solution uses dedicated Programmable Logic Controllers (PLC) to control equipment across your flowsheet. Process control ensures precision in your operations, helping increase energy efficiency and reduce wear. Our system also includes features to help you improve productivity and uptime, such as plant data management, trending, alarm management and data logging, resulting in a complete full-featured control system.

Advanced process control

FLS Advanced Process Control (APC) goes beyond process control to provide process optimisation – finding efficiencies in your operation and thereby reducing energy consumption, minimising wear and maximising productivity. It works to stabilise key processes by managing and correcting process disruptions. As such, wear is kept to a minimum and operations and maintenance costs are reduced.

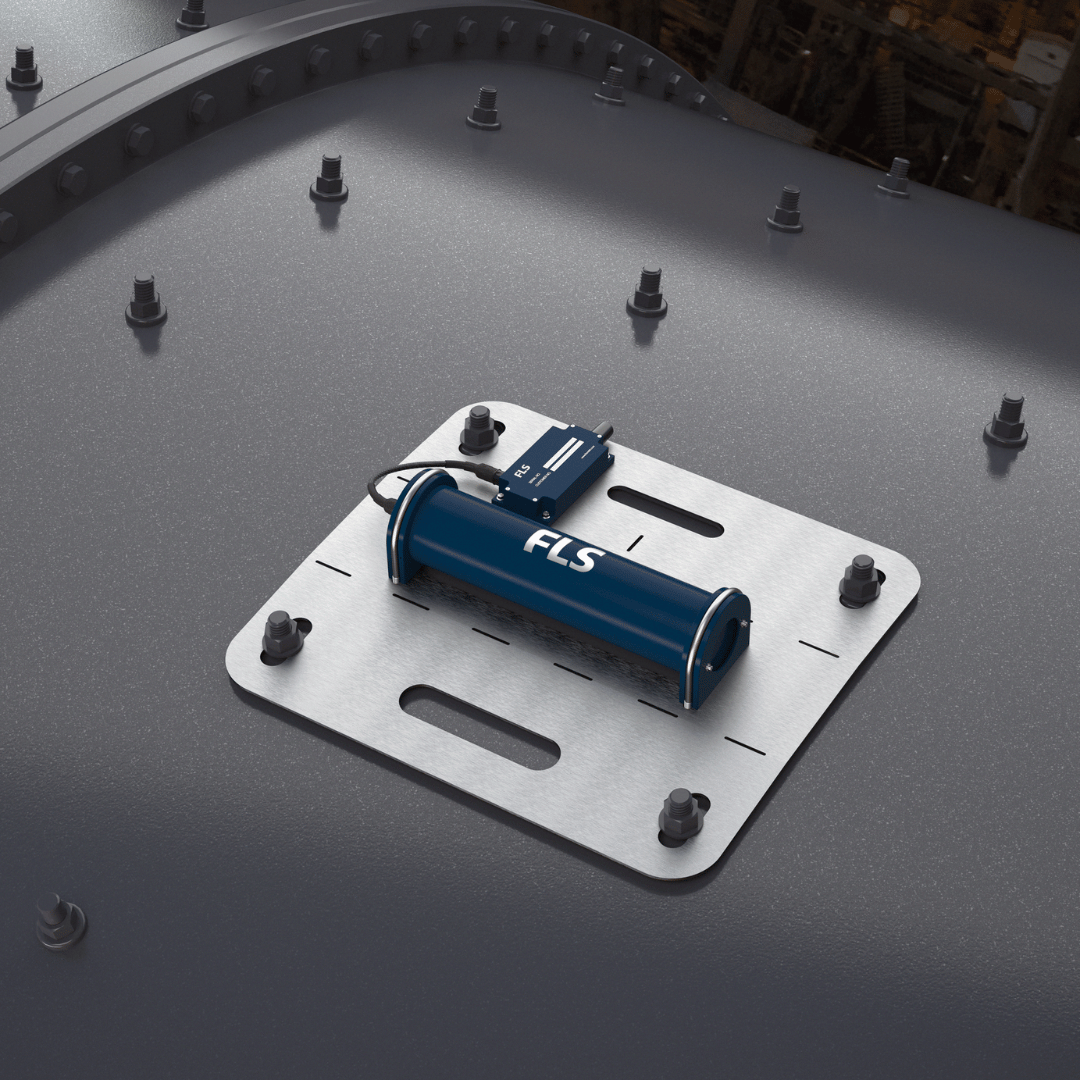

Sensors & vision systems

Our sensors and vision systems help maximise material recovery, improve operating efficiency, and drive your predictive maintenance strategy. They work in conjunction with other digital tools, such as our APC and our Asset Health & Insights services to provide the data you need for process optimisation.