High-rate thickeners

High-rate thickeners are designed to provide roughly 12 times the throughput of conventional machines of similar size. The key features for high-capacity thickeners are the feedwell design and the feed slurry dilution method. Our patented E-Volute™ feedwell offers Computational Fluid Dynamics (CFD)- optimised energy dissipation and solids distribution. E-DUC® and P-DUC feed-dilution systems maximise flocculation efficiency and settling rates.

Standard thickeners

Standard bridge-supported high-rate thickener designs are available for accelerated delivery and include either welded or bolted elevated steel tank designs up to 40 m in diameter and are ideal for many applications.

Traction thickeners

Typically installed in concrete tanks, traction thickeners have a stationary centre pier which supports the rake mechanism central bearing about which the rake arms rotate. The centre pier also supports the rotating feedwell and partially supports the rake mechanism and access bridge. The bridge supports the feed pipe or feed open launder. At the tank perimeter, the full-radius rake arm is supported on and driven by the drive unit (tractor). The drive unit runs steel traction wheels on a steel rail at the edge of the tank. Under appropriate climatic conditions, traction thickeners are an efficient, cost-effective design.

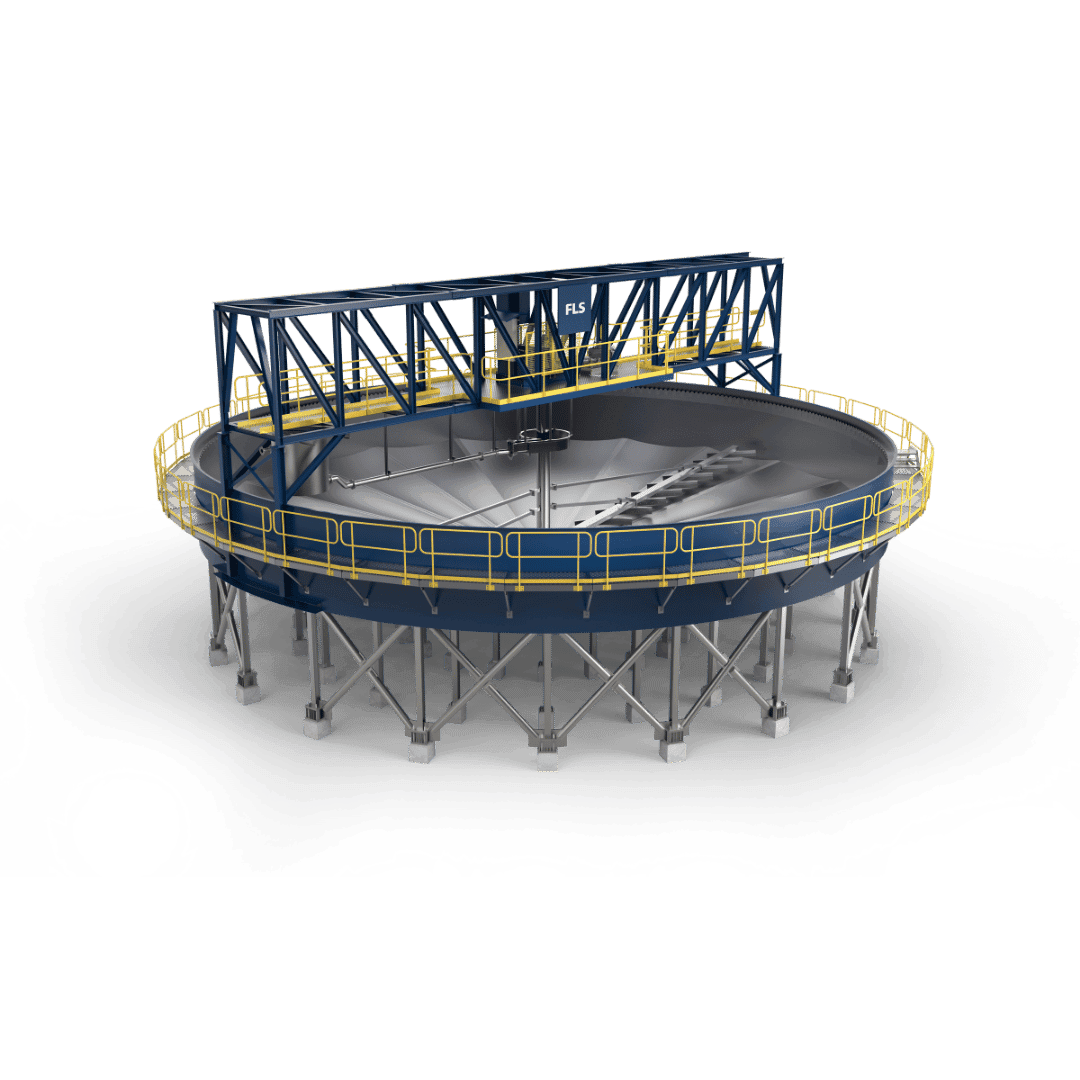

Bridge-supported and column-supported thickeners

EIMCO® and Dorr-Oliver® thickeners are available in both bridge-supported and column-supported designs. We offer beam- or truss-type bridges, depending on thickener diameter. In the bridge-supported design, suitable for thickeners up to 50 m in diameter, the drive is supported by the bridge, driving the rakes with a centre shaft. Column-supported design drives are supported by a stationary centre column of steel or concrete and are practical for thickeners up to 135 m in diameter.

Deep Cone™ thickeners

EIMCO Deep Cone thickeners produce underflows concentrated to near their limit of pumpability. The deep tank design maximises pulp concentration, and produces uniform, non-segregating underflow slurry with a paste consistency.