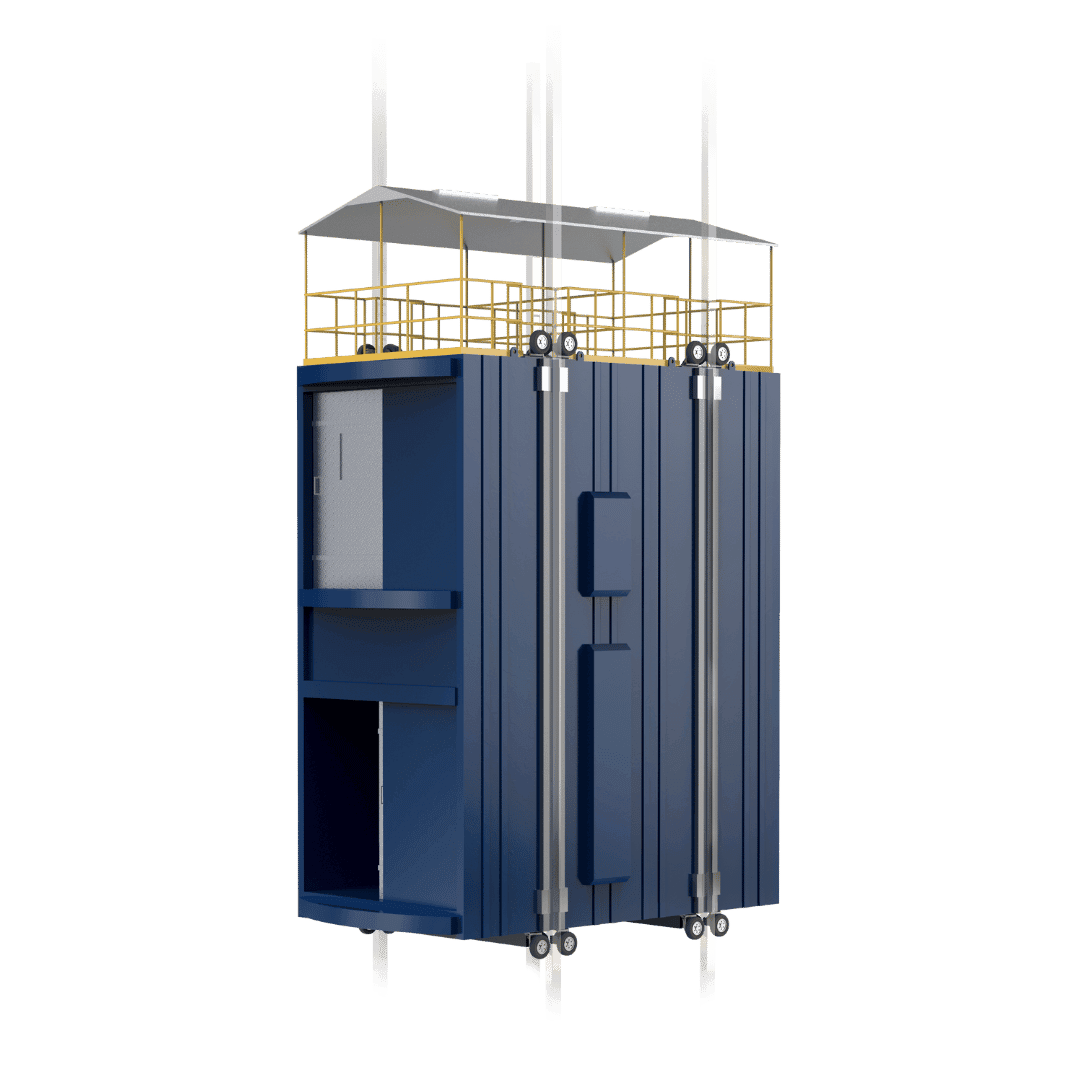

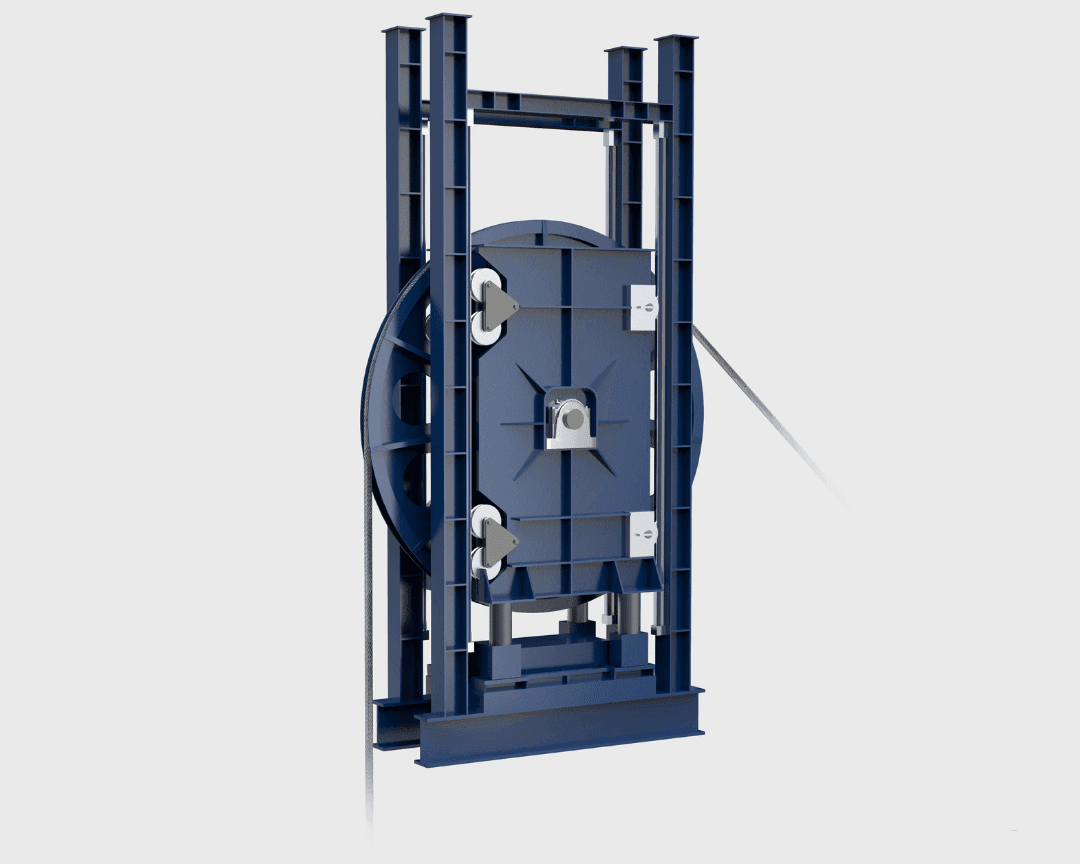

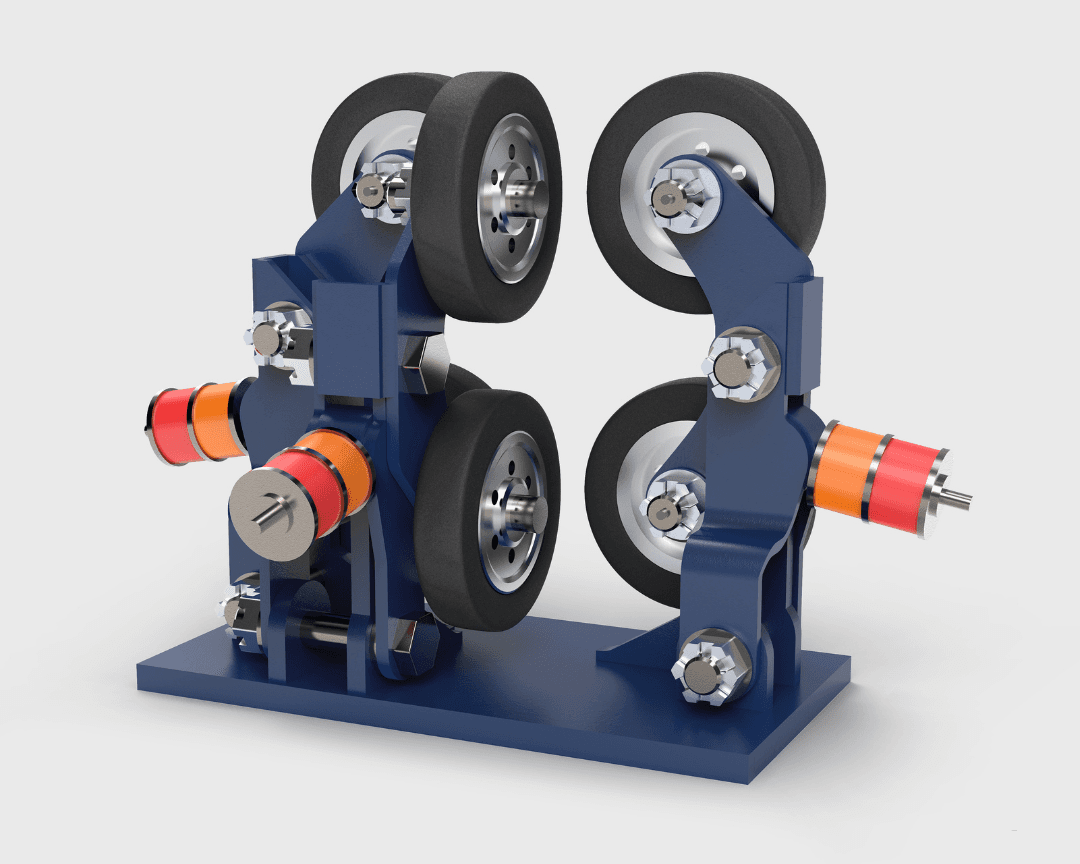

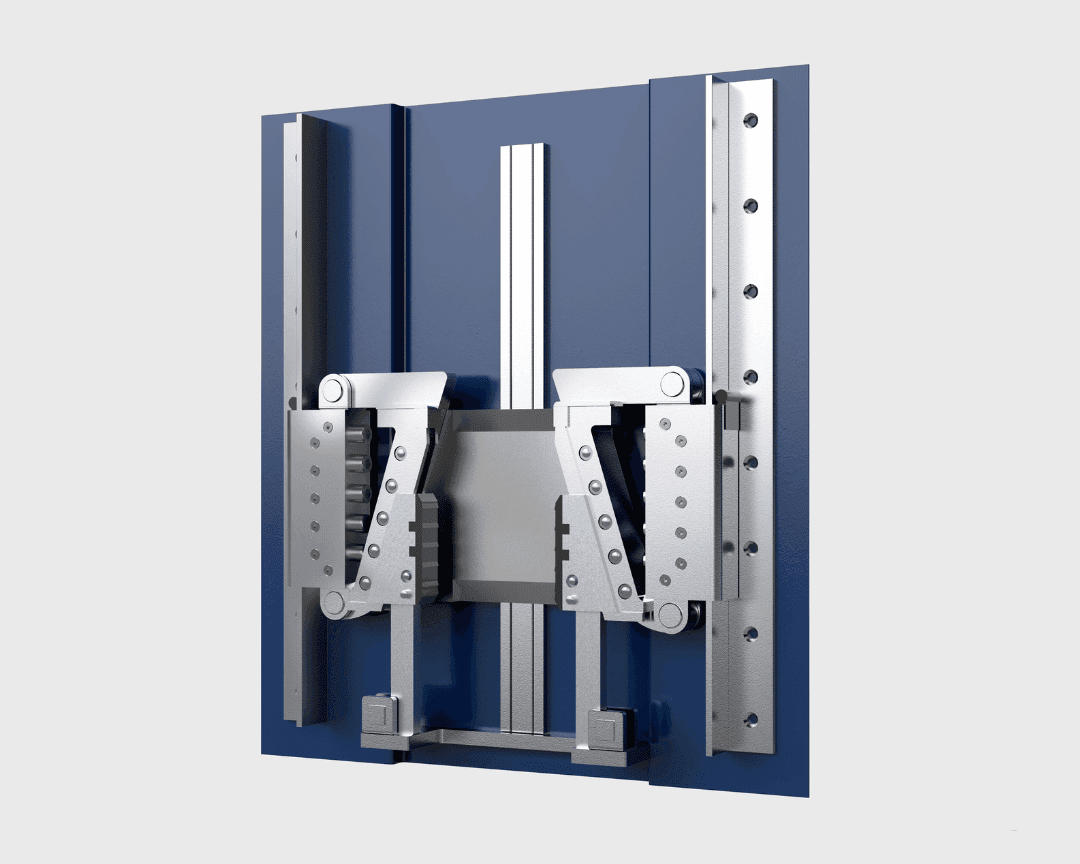

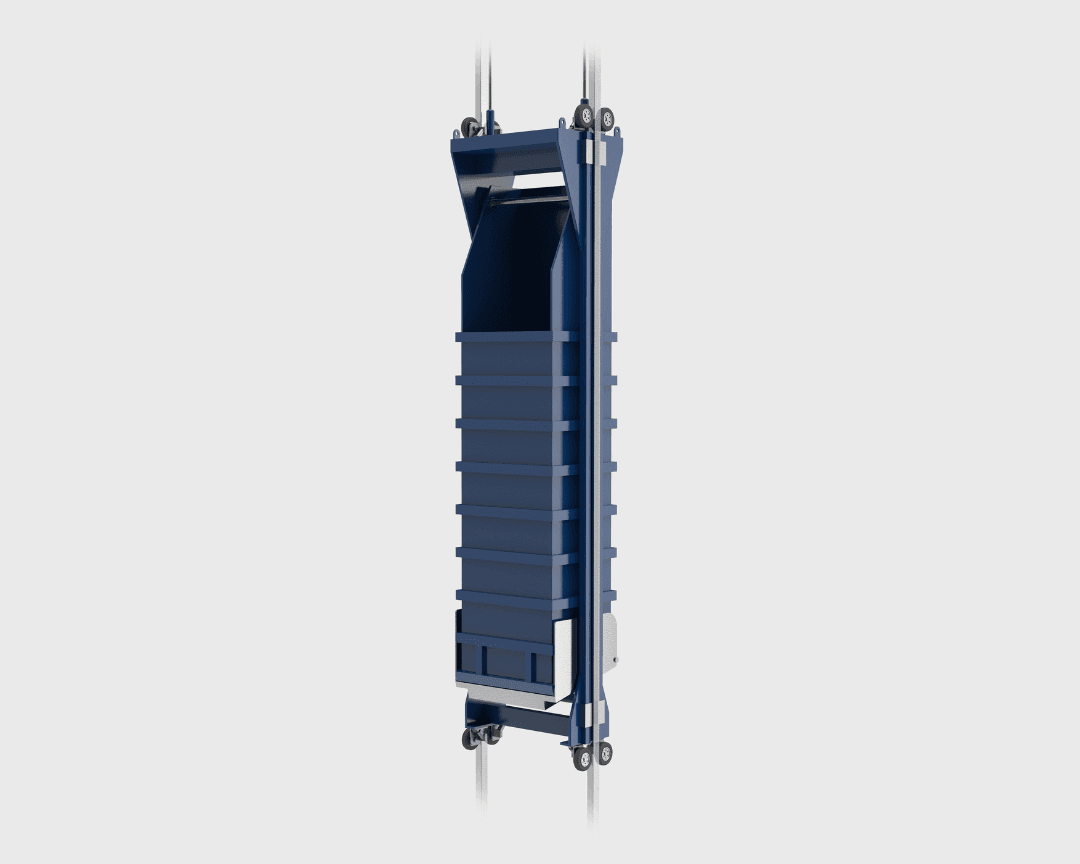

Our mine shaft equipment

Essential to a mine’s safety, efficiency, and productivity, the mine shaft is the vertical pathway connecting a mine’s underground workings to surface processing facilities. Selecting the right systems here can thus be the difference between success and a daily battle to meet targets. Customisable to the application and site requirements, FLS mine shaft systems cover the complete range of equipment. From the head frame to the shaft bottom, we ensure the mine shaft is up to the job, supporting safe and reliable performance, day in, day out.