Our slurry gravity samplers

Belt Drive Linear Sampler (BDLS)

Our linear cross-cut samplers are designed for optimal, fully representative sampling, emphasising robust and reliable operation in harsh environments. They are ideally suited to high volume flows where a horizontal launder section feeds into a large vertical chute.

- Positive, uniform drive mechanism ensures reliability and availability

- Avoid overflow and prevent splashing

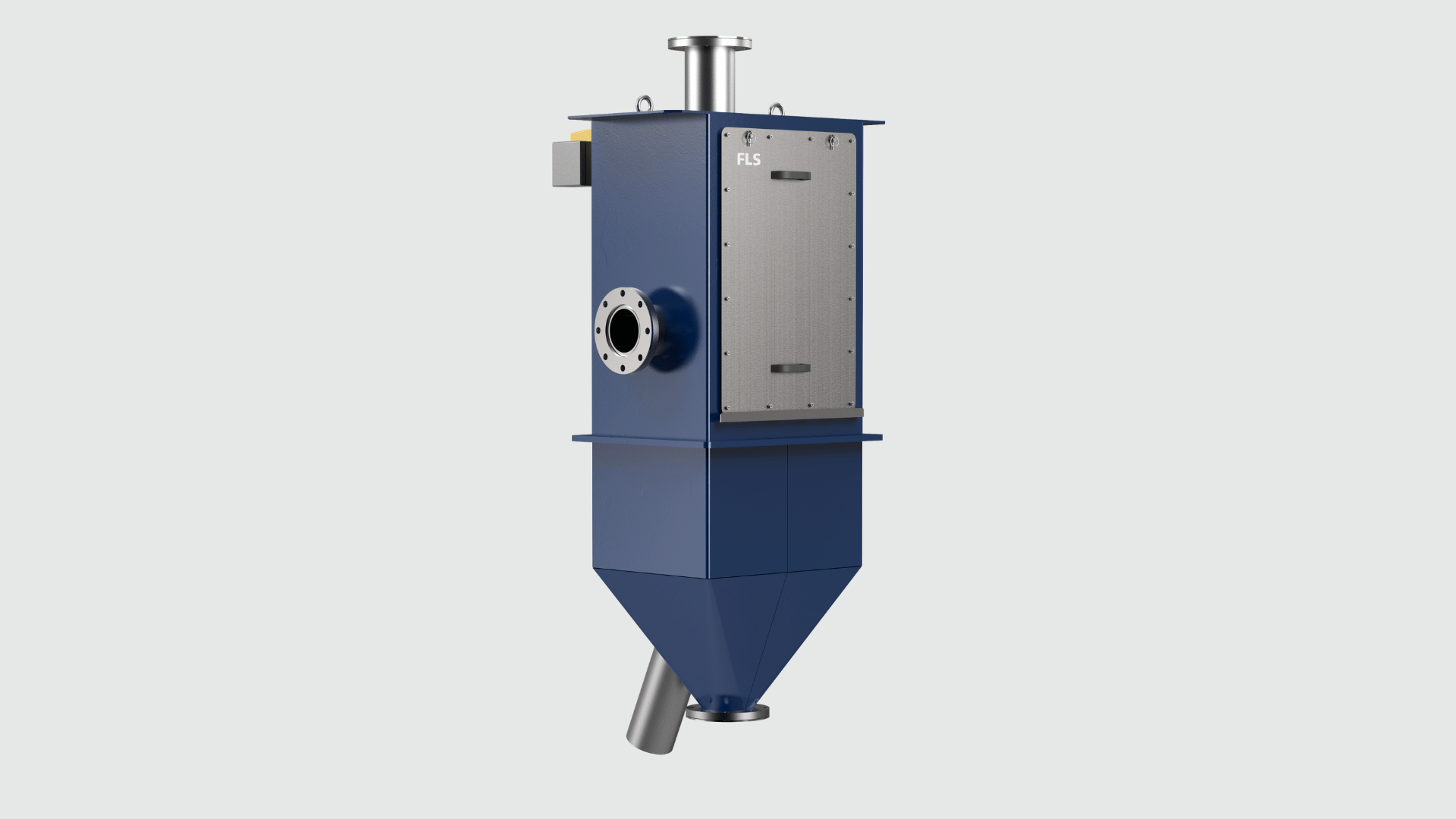

Vezin Sampler (VS)

The rotary Vezin slurry gravity sampler is often used for secondary or tertiary cross-stream sampling in metallurgical accounting applications. It suits smaller sample flows and is typically timer-controlled or dependent on the operation of the preceding sampler in the system.

- Square design simplifies installation and maintenance

- Easily change cutter size and number

- Designed for minimum maintenance

Moving Pipe Sampler (MPS)

Our moving pipe samplers are self-contained units for installation in gravity flow, non-pressurised pipe systems. Ideal for smaller diameter pipe work, due to their simple flange-to-flange installation, the feed falls through the sampler, which contains a fixed cutter and a flexible pipe moving back and forth across the cutter, perpendicular to the aperture.

- Minimal moving parts

- Inspection openings for easy cutter maintenance

- Pipe park positioned outside the cutter aperture