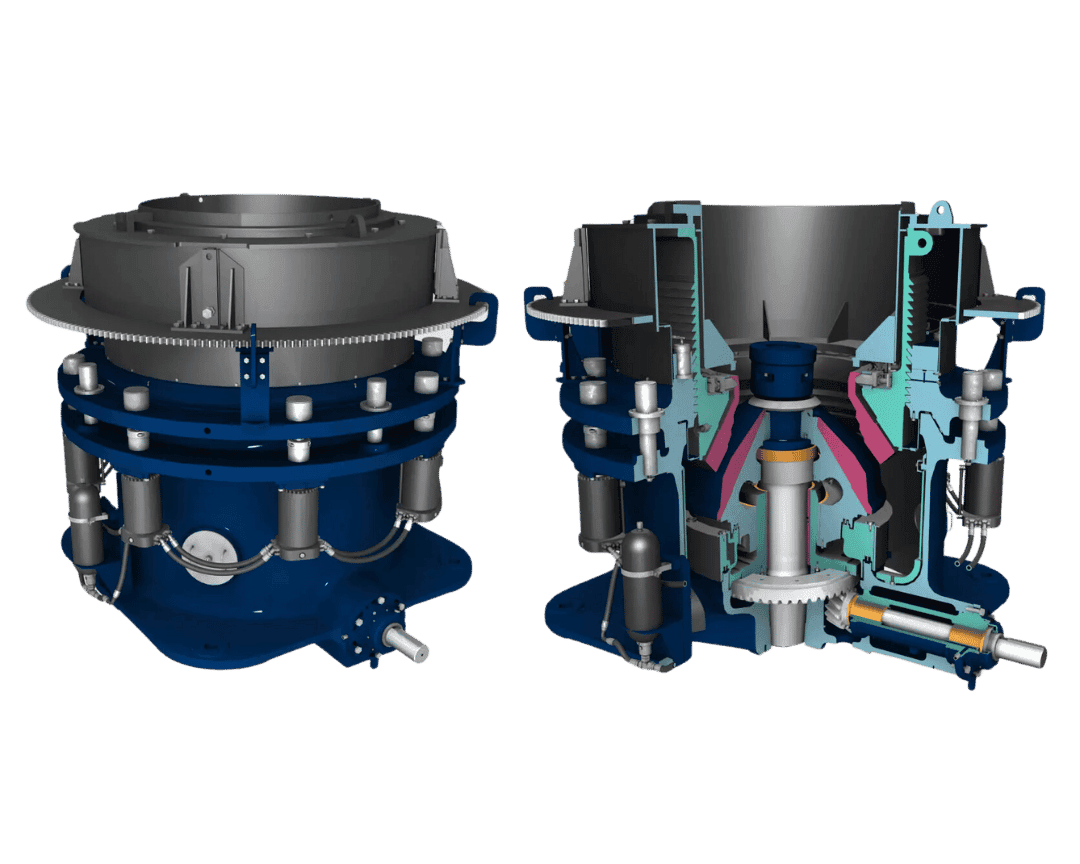

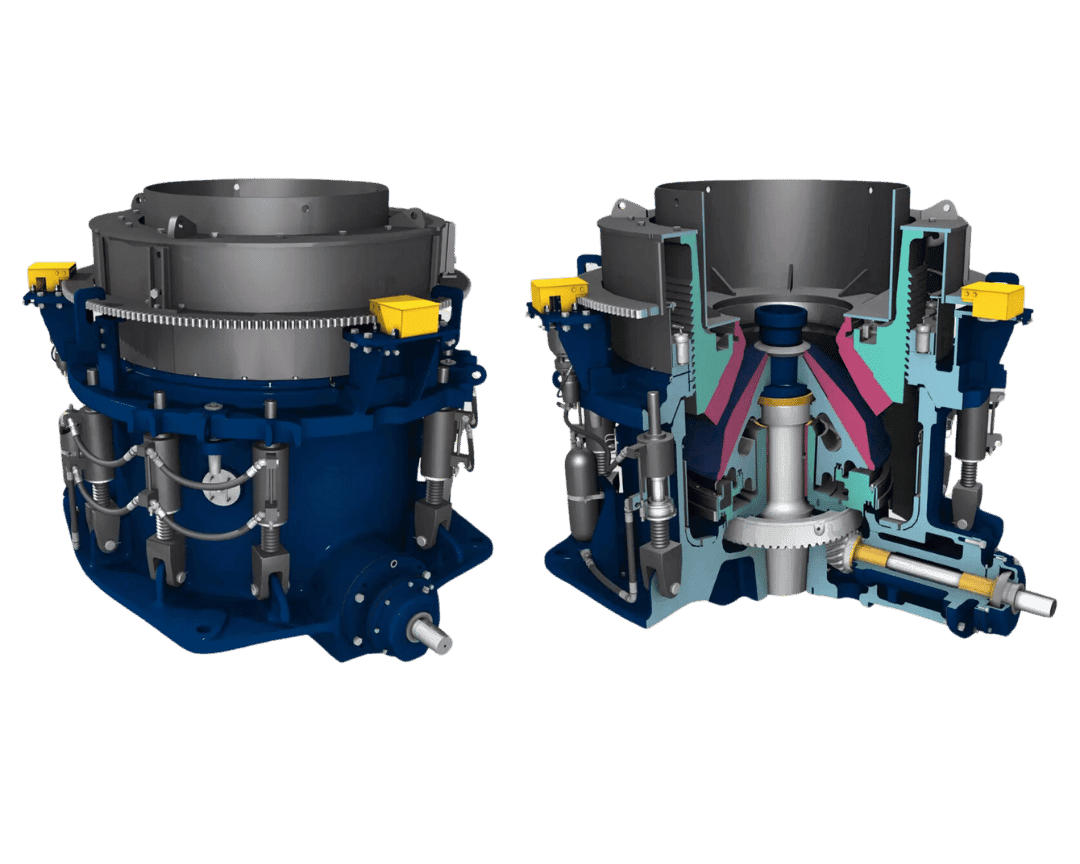

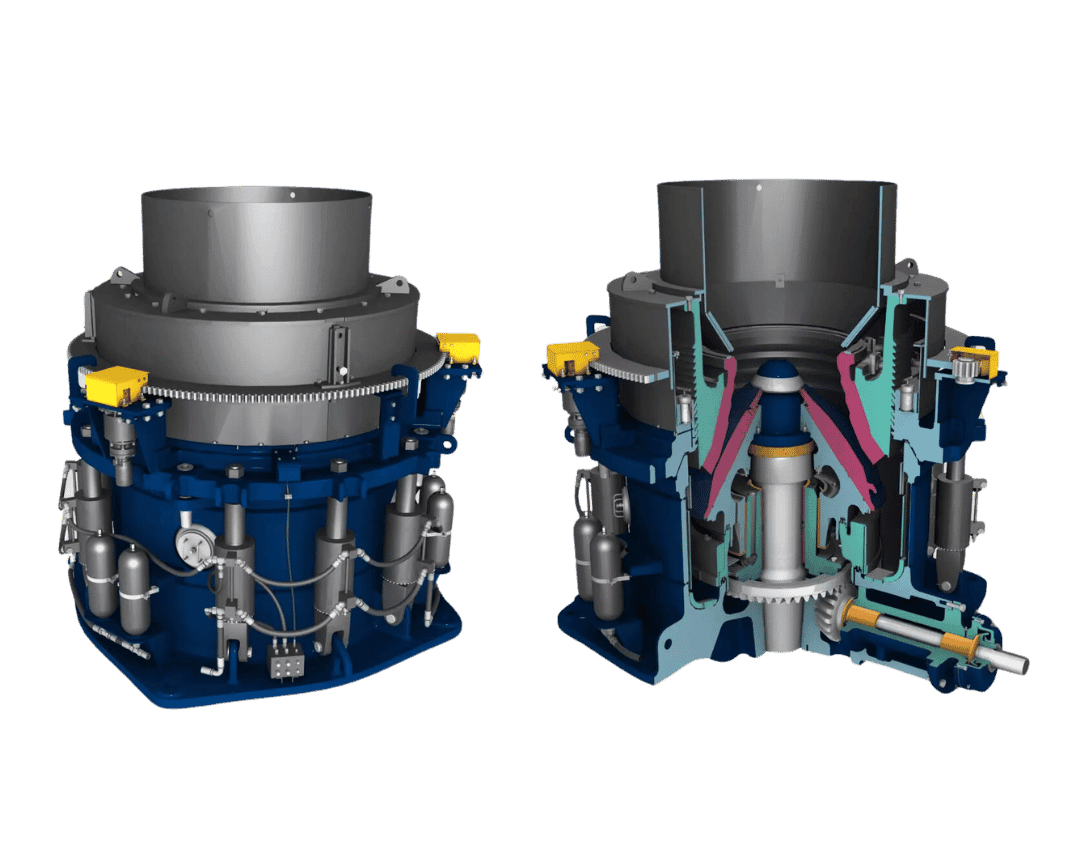

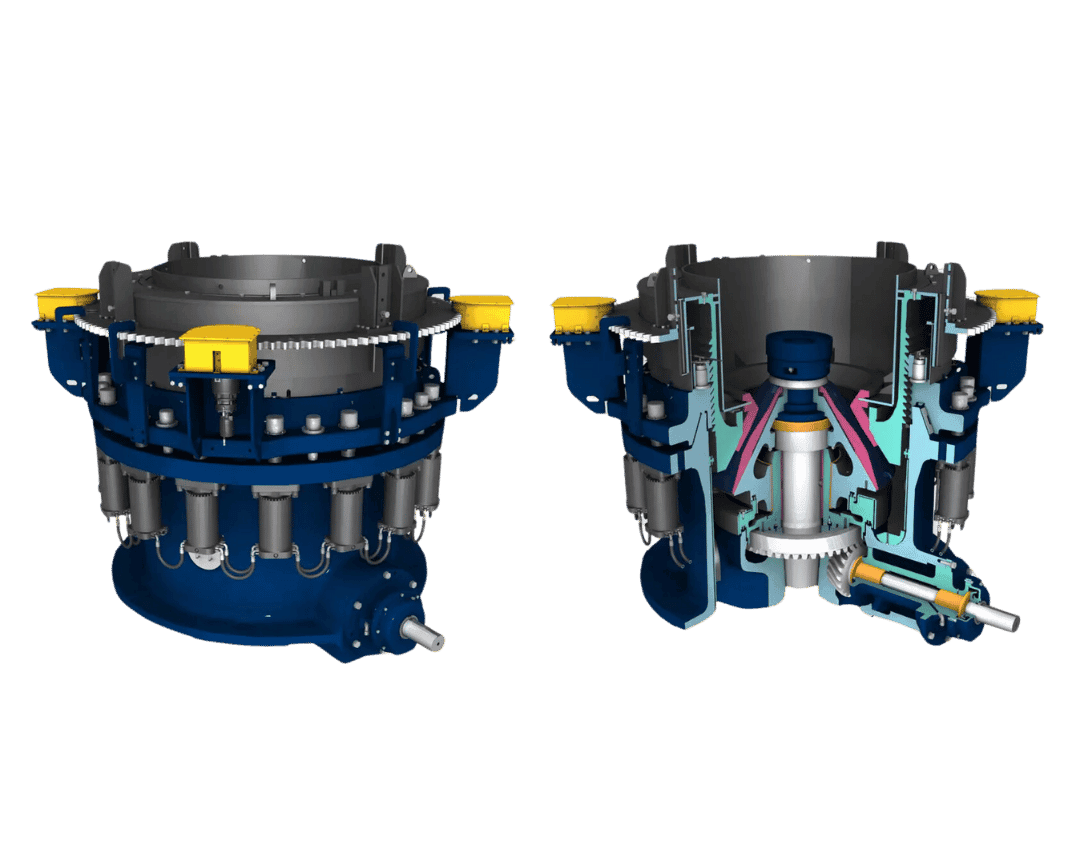

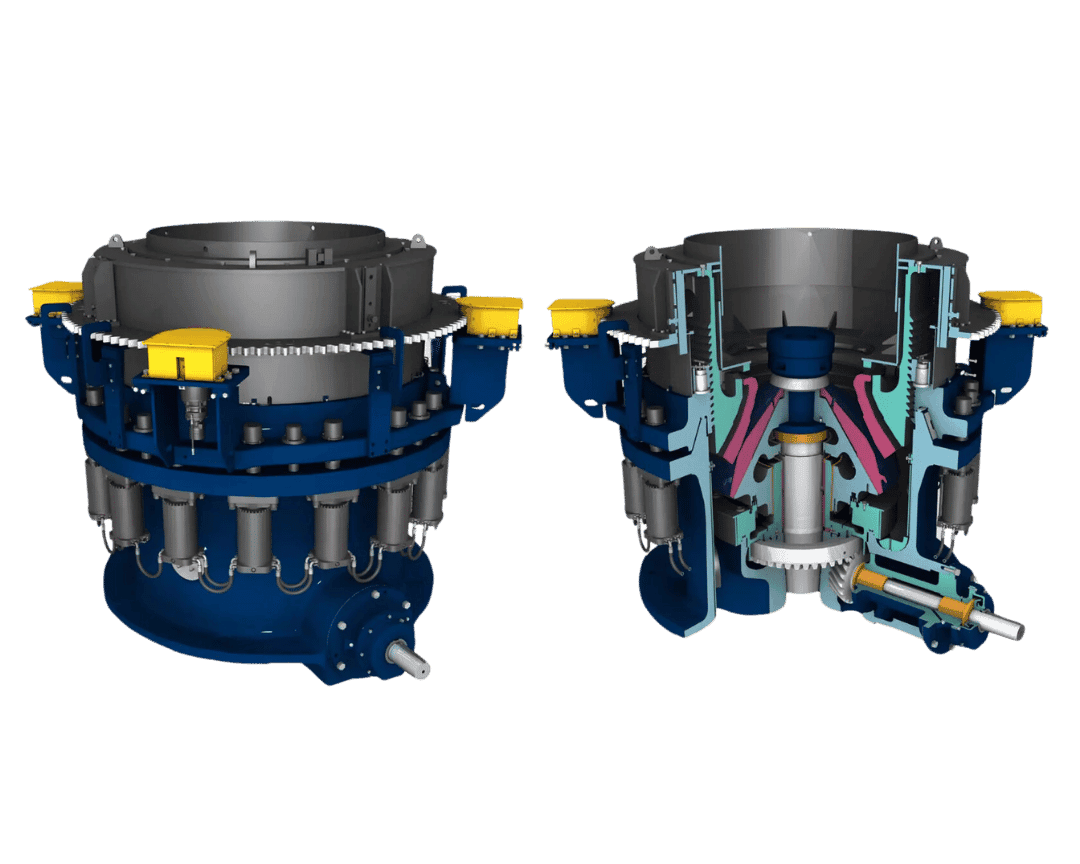

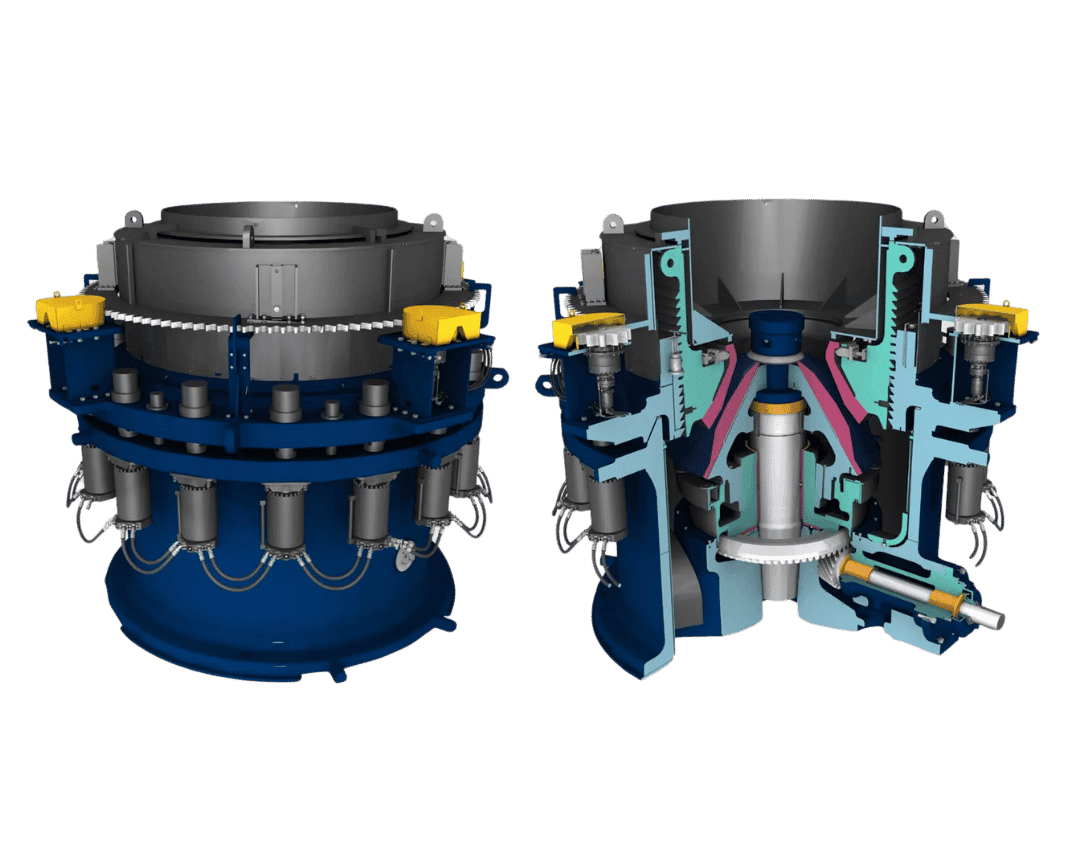

High crushing force across a wide range of applications

FLS Raptor cone crushers deliver superior crushing force, resulting in higher production and finer output sizes. Their robust design allows them to handle a wide range of materials, making them suitable for diverse applications like mining, aggregates, and sand production.