Our sample dividing equipment

Essa® RSD Bench Top Splitter

The RSD001 Bench Top Splitter uses rotary sample dividing technology to achieve split ratios from 2 – 50%. With a 1.8L hopper capacity, it's compact, easy to use, and ideal for a variety of industries, including geochemical labs and industrial applications. It features an adjustable electromagnetic vibratory feeder for precise, uniform sample flow. Parameters including feed speed and split ratio can be customised. Its compact, ergonomic design allows for easy setup and relocation, while stainless steel and aluminium construction prevent corrosion and contamination. Compliant with industry standards, this system enhances both operational efficiency and sample quality in diverse lab environments.

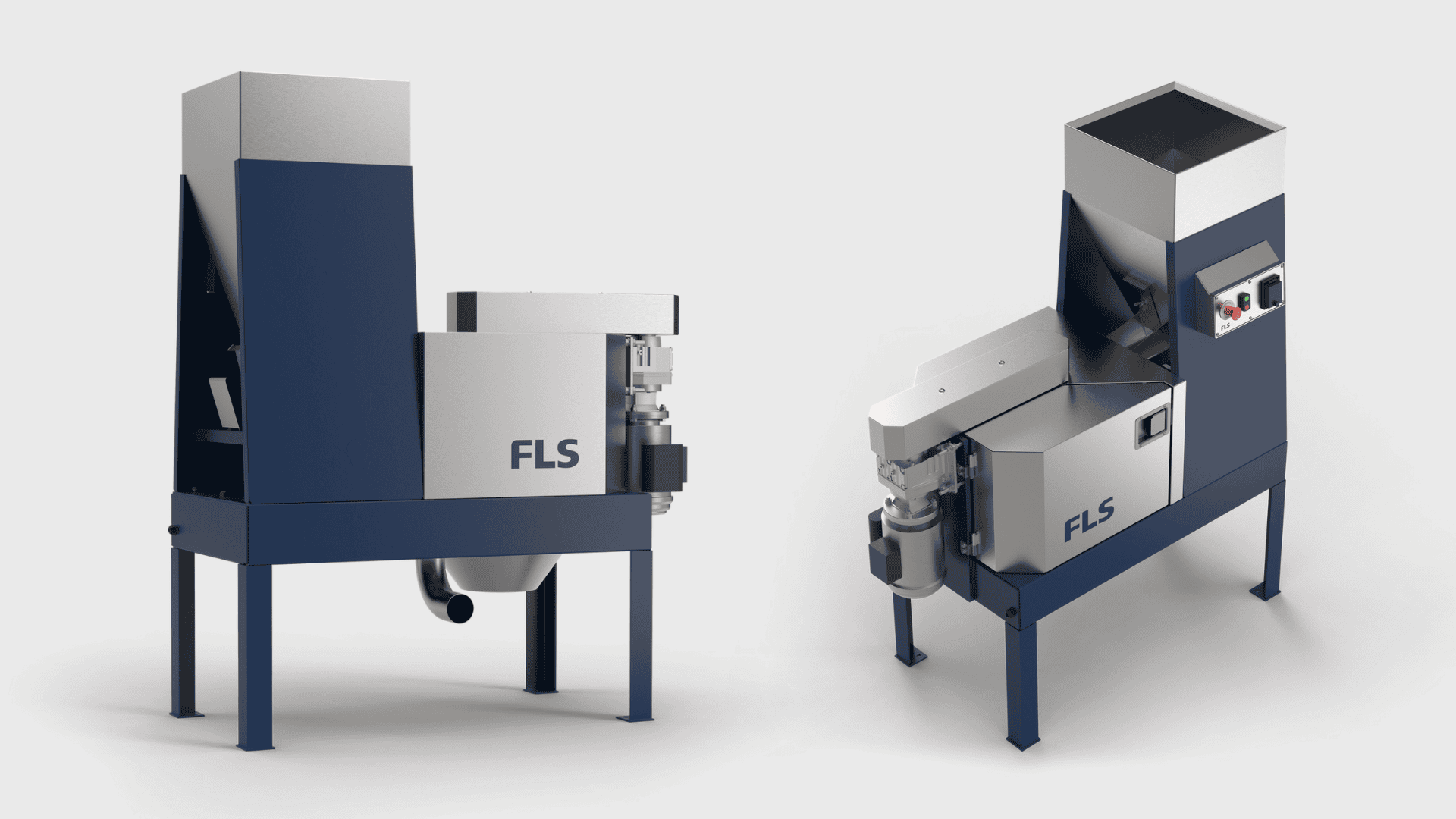

Essa® RSD Series Rotary Sample Dividers – Bucket Type

The Essa units provide consistent, mechanically correct sampling. They cut even representations of larger samples according to industry standard sampling guidelines. This is achieved by feeding the entire sample at a controlled rate as a falling stream. The machine then divides this sample into equal segments by the action of a “circle” of segmental buckets being rotated beneath the stream.

The rotary sample divider bucket type range is appropriate for a wide range of laboratory applications. The hopper sizes range from 5 L through to 60 L, which allows you to cater to different quantities requiring sampling. This is complemented by a wide range of sample bucket sizes, to take various percentages of the sample according to your requirements. Buckets are available in a range of convenient standard cut designs of 8.3% (12 buckets), 10% (10 buckets), 12.5% (8 buckets), 16.67% (6 buckets) and 25% (4 buckets).

Essa® RSD Series Rotary Sample Dividers – Residue Type

Like the RSD bucket-type unit, the Essa RSDR sample divider is designed to increase your productivity. It offers the same sample reliability, while neatly capturing the sample residue, so you save on labour time.

The RSDR offers high-quality, representative sub-samples using a falling stream and rotating buckets, which can be adjusted for different cuts and sample volumes, while the remainder of the feed passes through to a discharge system – either a mechanical conveyor belt, or a handy removable collection bucket. Clean-up is easy, with the RSDR unit neatly and cleanly capturing the unwanted portion of the sample.

Different sized buckets can be fitted to vary the percentage captured, according to your needs. If two, or up to 12, separate cuts are required, more buckets can be added. Buckets are available in a range of convenient standard cut designs of 5%, 10%, 12.5%, 15%, 20% and 25%. A range of hopper sizes is also available, from 10 L to 60 L, to cater for whatever your sample volume might be.

The simplified bucket positioning system reduces load time between samples. Plus, you are handling less buckets – less buckets to load, unload and clean. All this means you can confidently process more samples in less time. RSDR sample dividers can also be adapted for automated installations, for the ultimate in sampling efficiency.