Join the MissionZero Mine vision as an early adopter

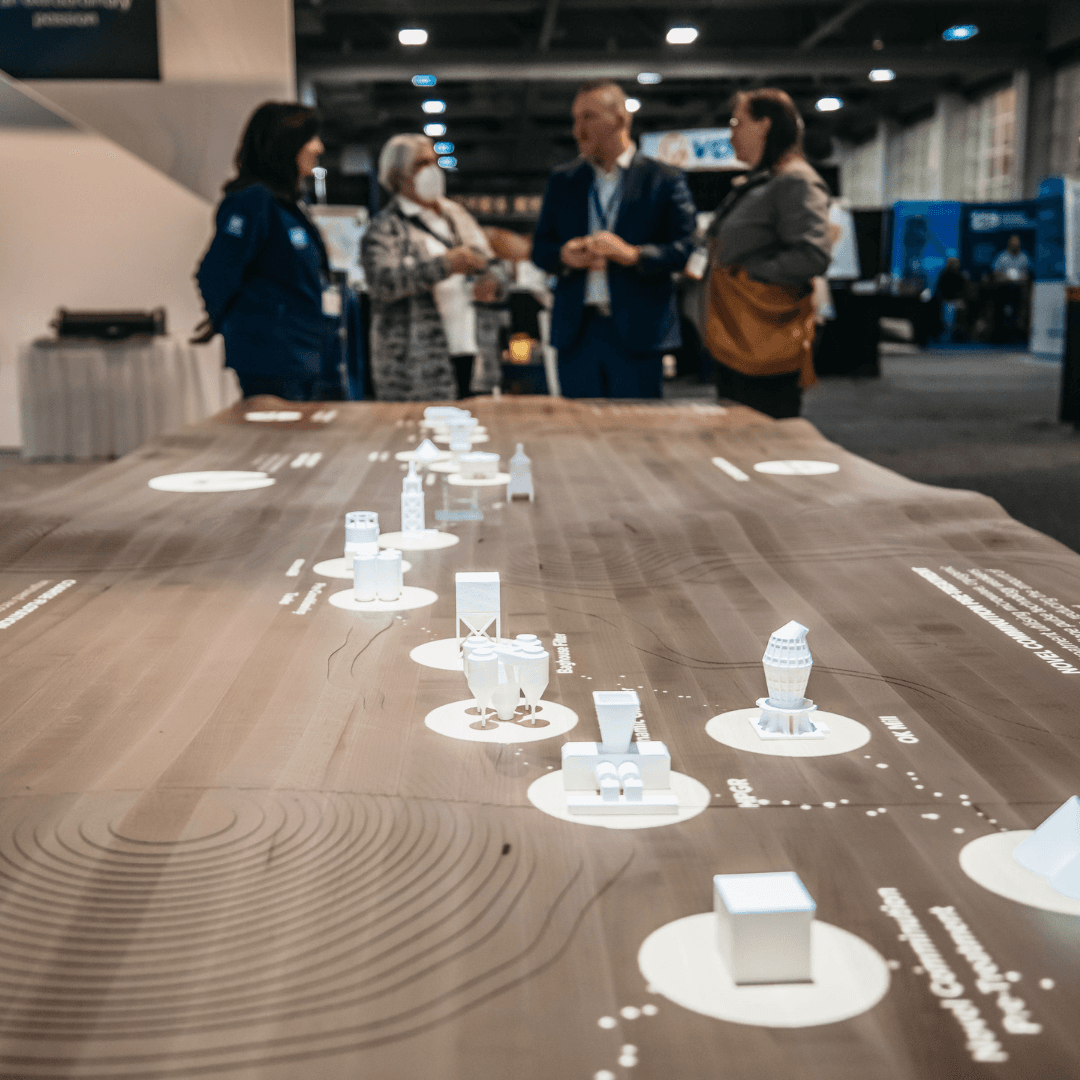

As part of the MissionZero Mine innovation cycle, FLS seeks to partner with forward-thinking mining companies for pilot trials and early deployments. These provide critical insight into how the technology will work in real-world applications while allowing the mining company to explore new opportunities to take its process to the next level.

Trials and early deployments are designed to integrate easily into existing operations. Pilot equipment is skid-mounted for easy shipment, set-up, and commissioning at the mine site, where it can be compared side-by-side with conventional processes. This allows mineral processing plants to see how these latest developments can optimise recovery rates while reducing key inputs, such as power consumption, energy costs, plant footprint, and water consumption.

During the pilot phase, FLS works with the client to optimise the system and ensure it delivers the expected improvements. Depending on the results of the pilot phase, FLS can also assist with technology scale-up to production levels.

Beyond these operational benefits, early adopters position themselves as leaders in responsible mining at a time of increasing pressure to reduce environmental and social impact. They also gain both a critical early voice in the development of MissionZero Mine mineral flowsheets of the future and a key competitive edge over other operators.