Safe and robust feeding and mine shaft systems

High-performance transport systems play an essential role in mining operations. We have supplied feeding equipment and complete mine shaft systems, for decades, ensuring we have the industry-leading credentials and product range to deliver a solution that meets your needs.

Explore our feeding solutions

Total lifecycle support for your material handling equipment

Our total lifecycle support assists and advises you through design, installation, commissioning, troubleshooting, and optimisation of your feeding equipment and complete mine shaft systems. Our comprehensive aftermarket services include OEM-quality spare parts and consumables, maintenance support, equipment refurbishment, and upgrades.

Want to talk? Reach out to our experts

Frequently asked questions

FAQs for feeding

Feeders play a crucial role in handling and transferring dry bulk materials in mining operation. Whether receiving material from truck dumping stations or extracting material from storage, the feeding process regulates material flow to downstream process steps, preventing overloading and ensuring stable, efficient operations.

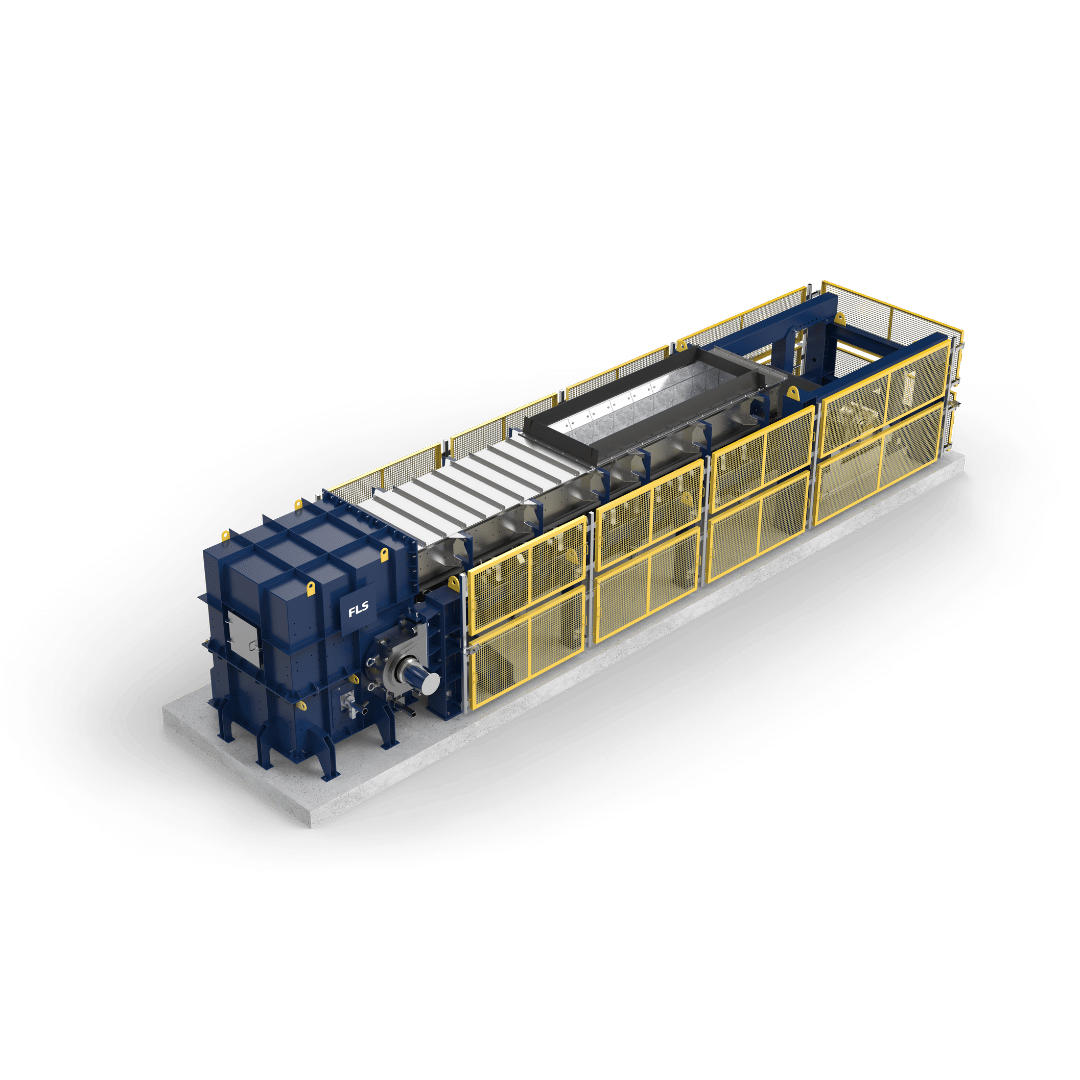

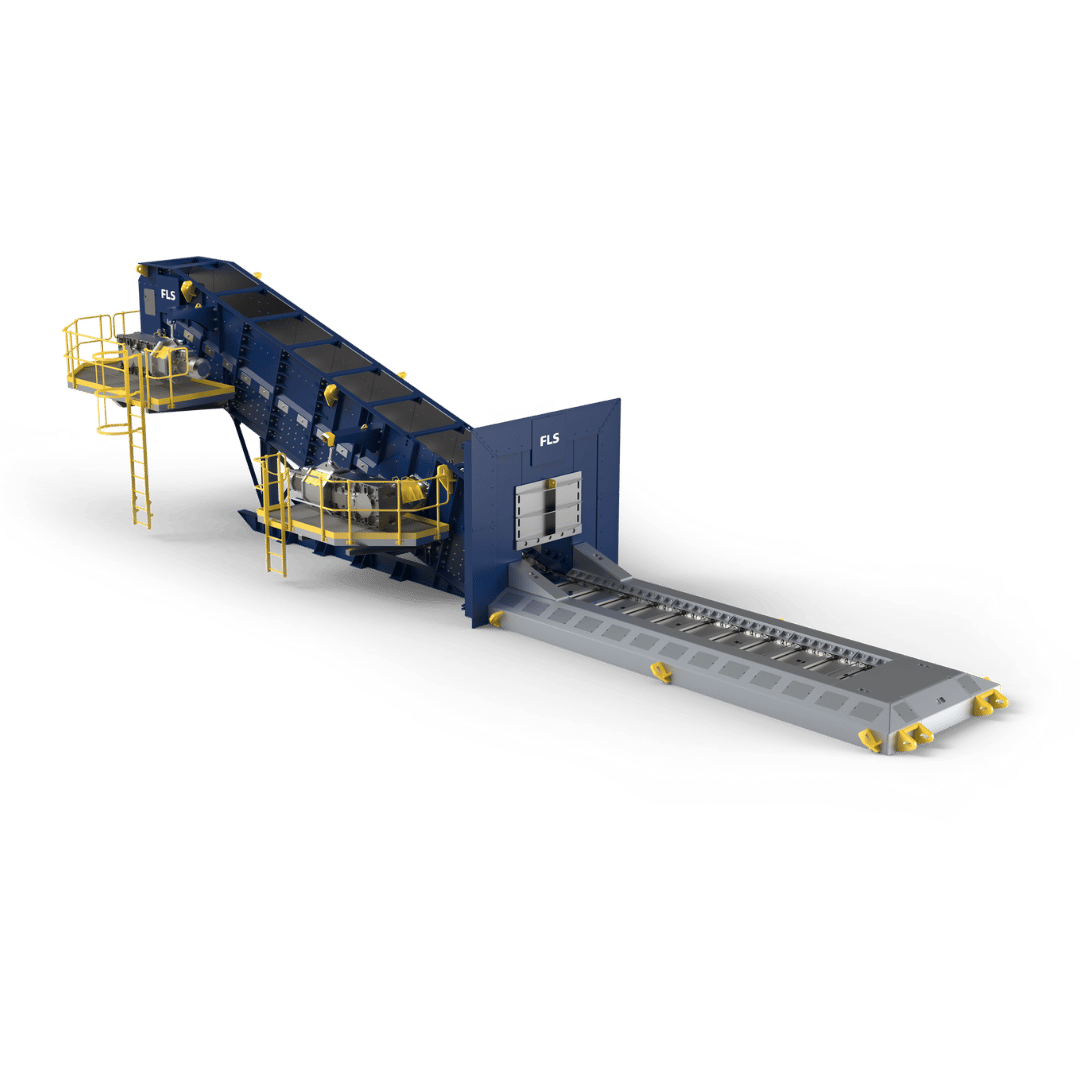

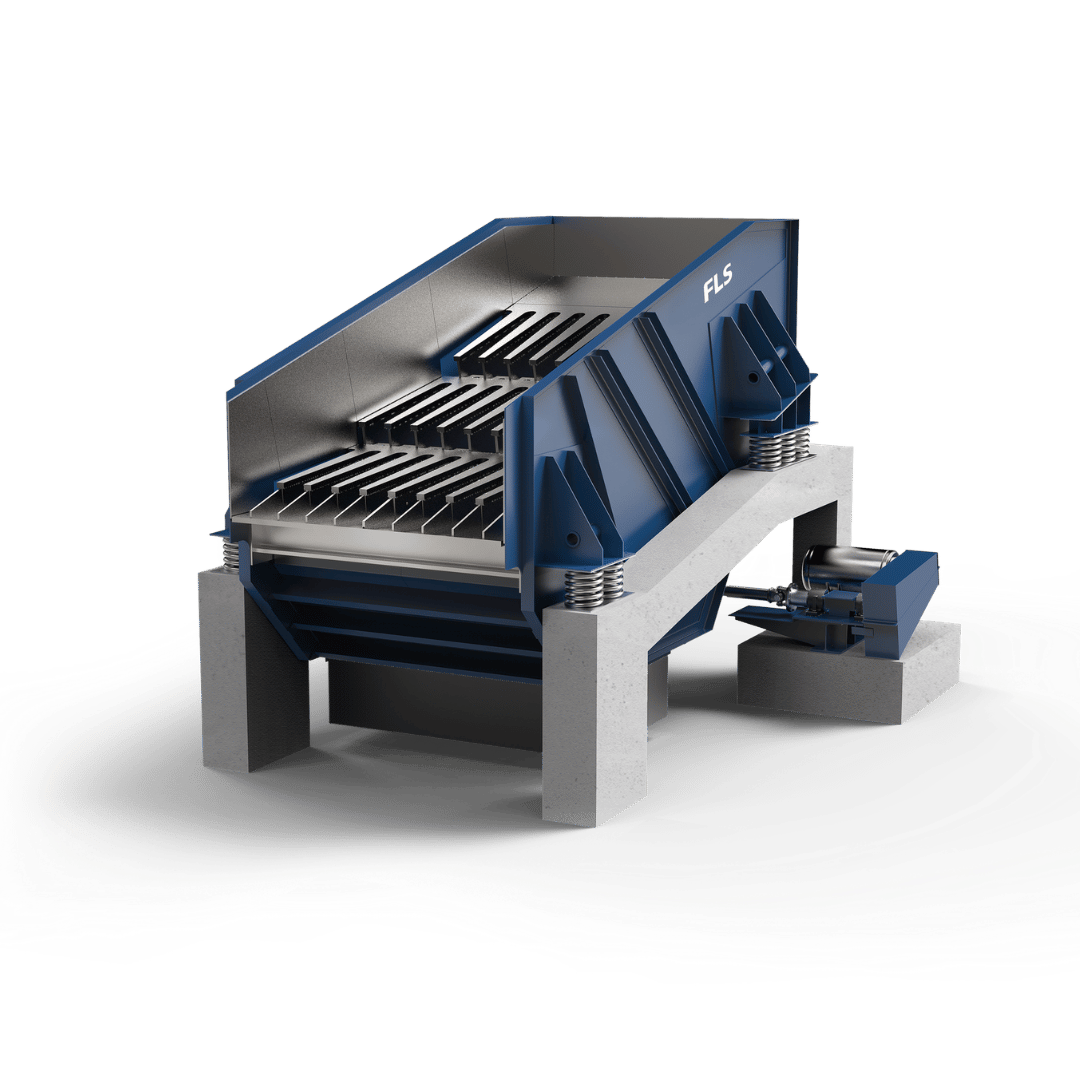

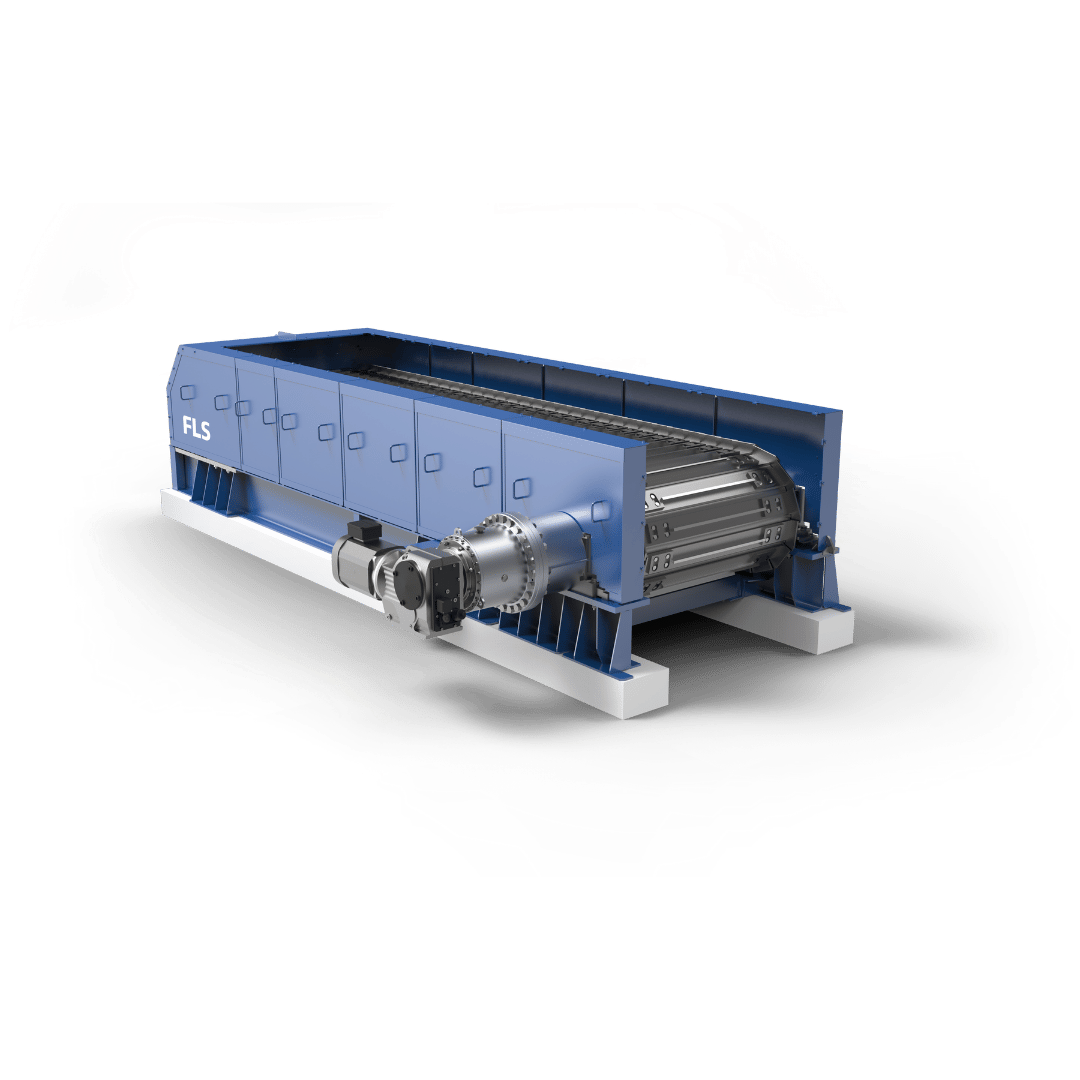

Several types of feeder may be used in mining operations, depending on the application, material characteristics, and throughput required. Common types include heavy-duty apron feeders, belt feeders, hybrid apron belt (HAB) feeders, reclaim feeders and feeder breakers, and vibrating grizzly feeders.

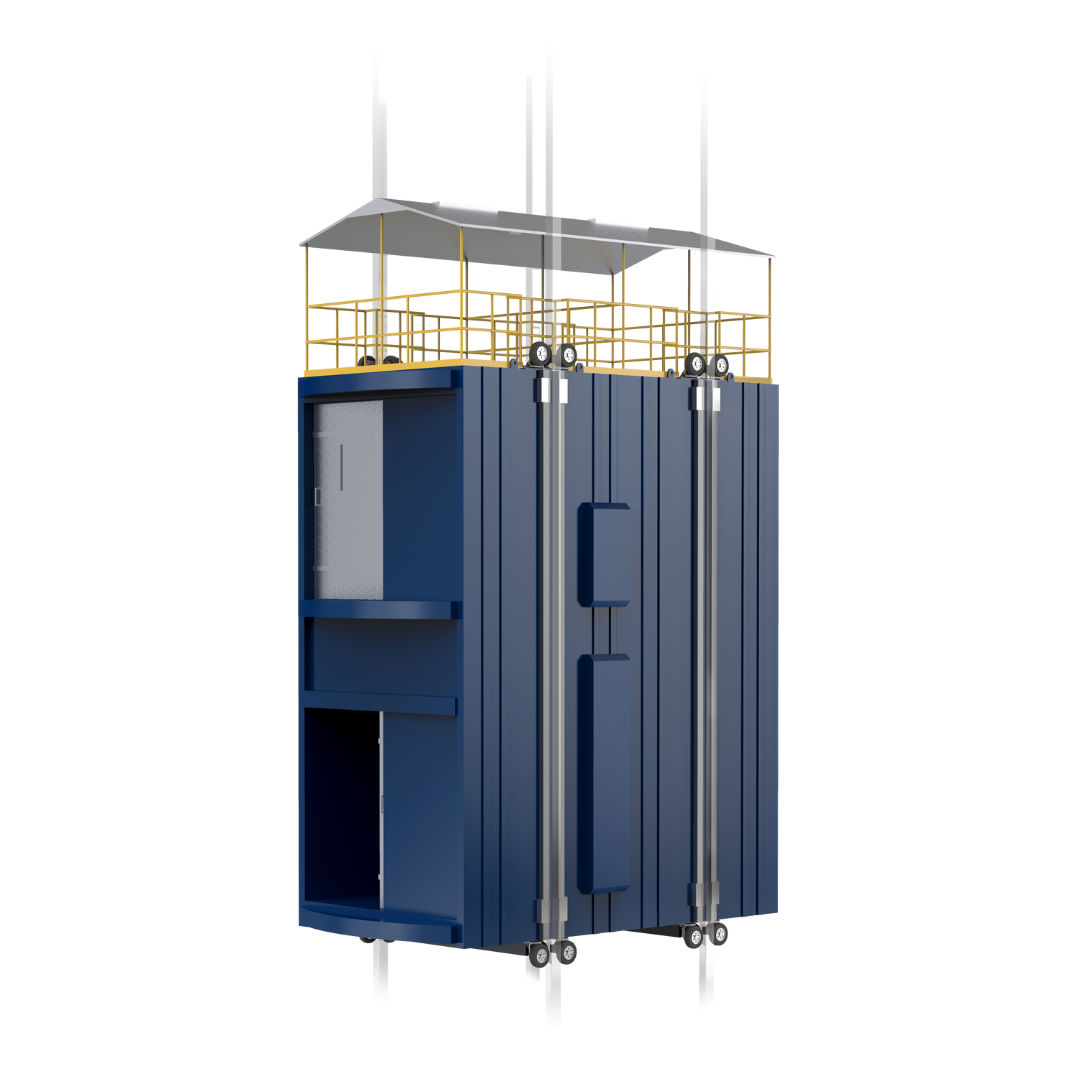

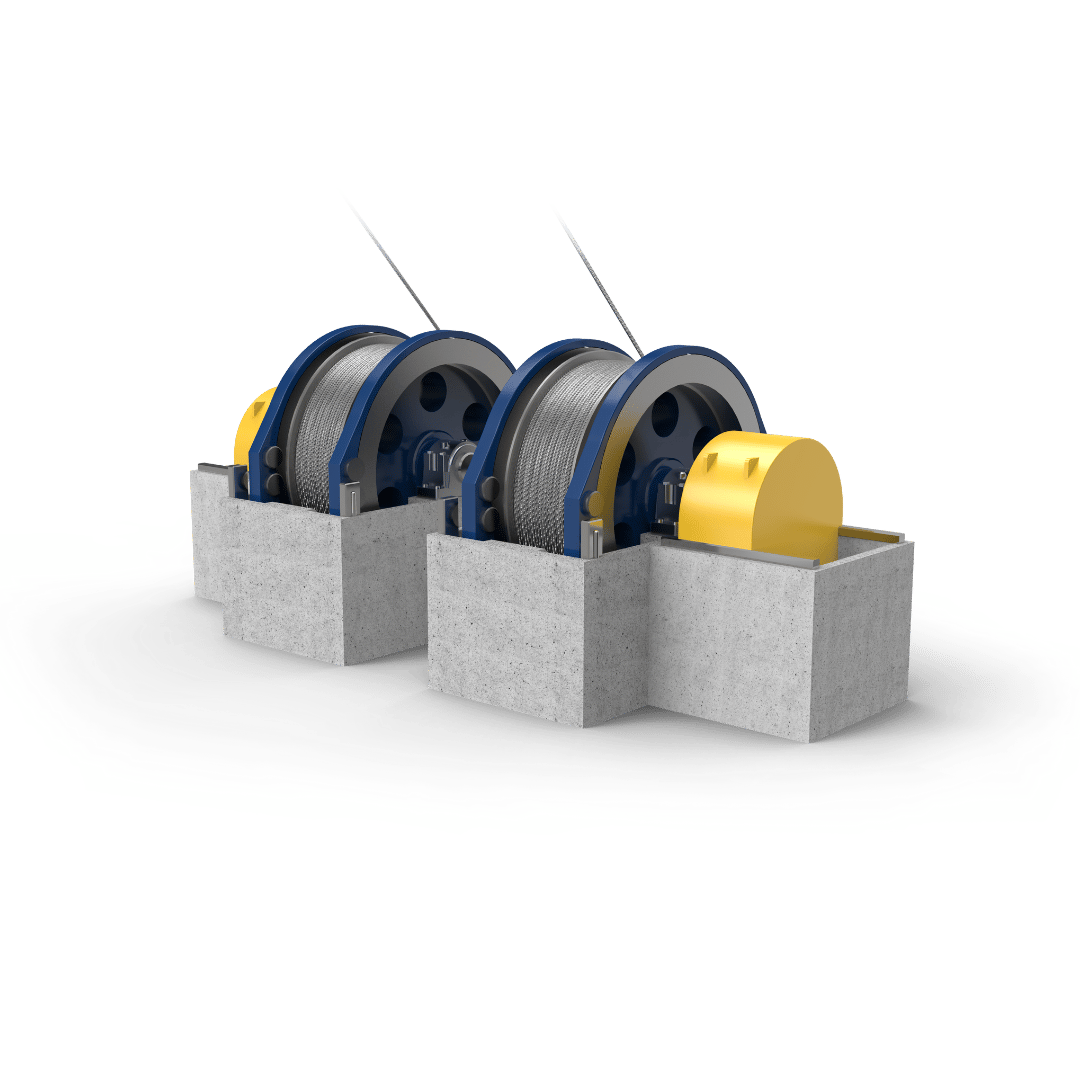

Mine shaft systems link underground mines to the surface, allowing safe and efficient transport of mined material to aboveground processing and storage facilities, and of personnel and equipment to underground workings. Mine shaft systems comprise several interlinking technologies including head frame equipment, mine shaft hoists, cages and skips, and safety equipment, such as brakes and arrestors.