Compare ball mills

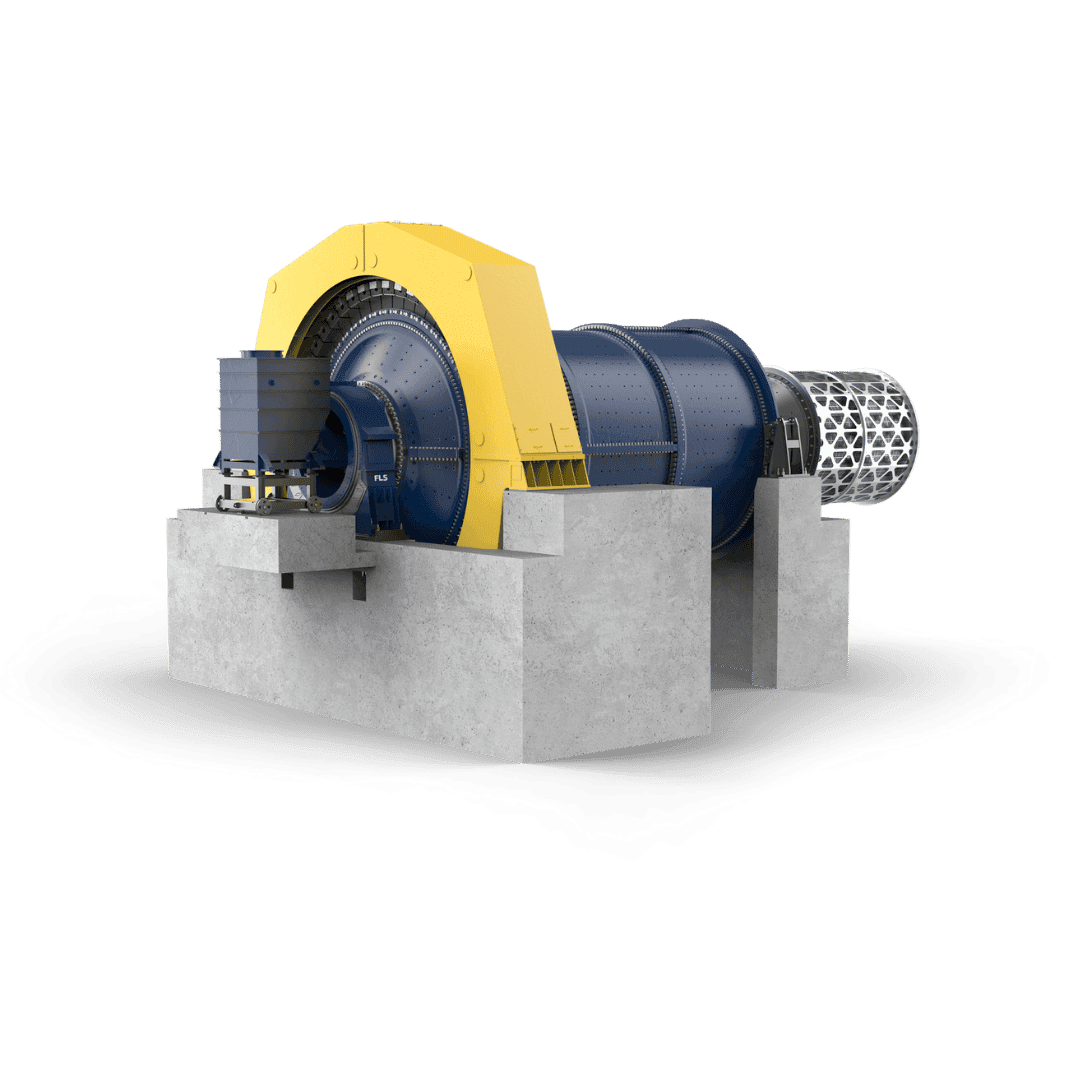

Ball mills can be configured to suit the project demands with design features as follows:

- Support Method: Trunnion-supported or shell-supported

- Drive Train: High speed with reducer, low speed direct coupled, or gearless (wrap-around motor). Geared solutions can be single or dual pinion with references up to 10,000 kW per pinion.

- Main Bearings: Hydrostatic or hydrodynamic. Sleeve or multi-pad (self aligning).

Add-ons of ball mills

- Mill wear parts – Increase service life and efficiency with advanced mill liners and wear parts.

- LoadIQ – Optimise mill loading with our specially devised sensor.

- Advanced Process Control – Improve grinding efficiency with our advanced process control system.