Audits & Studies

Every project begins with a site inspection and audit, where we can find out what’s not working and why. Our site inspections use a checklist to assess performance against a baseline, while our audits analyse performance data against guarantees to discover the performance gap. We’ll then make recommendations for adjustments or improvements to the filter to bridge that gap and achieve your performance goals.

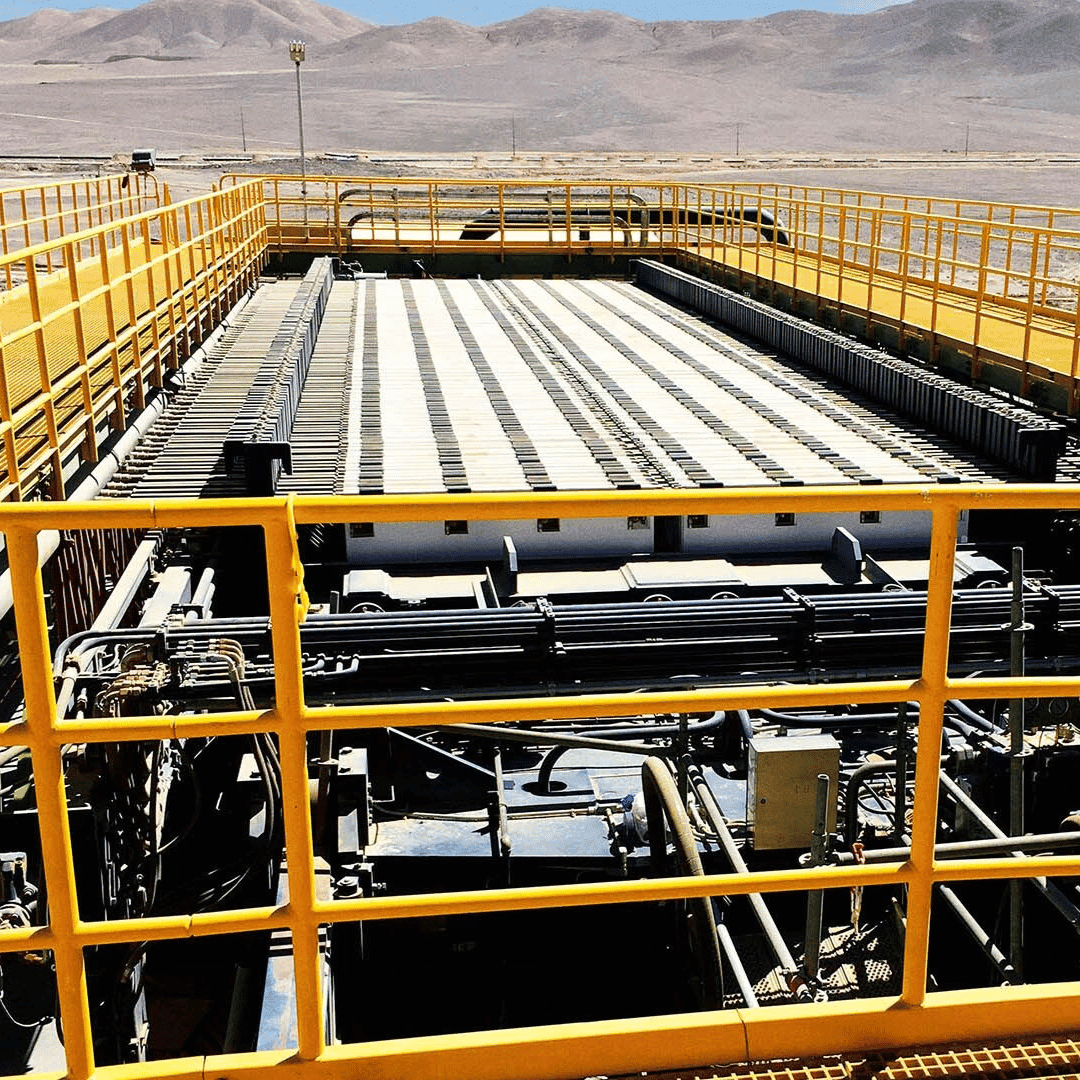

Upgrading

There are several possibilities to upgrade your mining filtration equipment, but as with all our upgrade services we prefer to take a bespoke approach based on your challenges and performance goals. Talk to us about your needs.

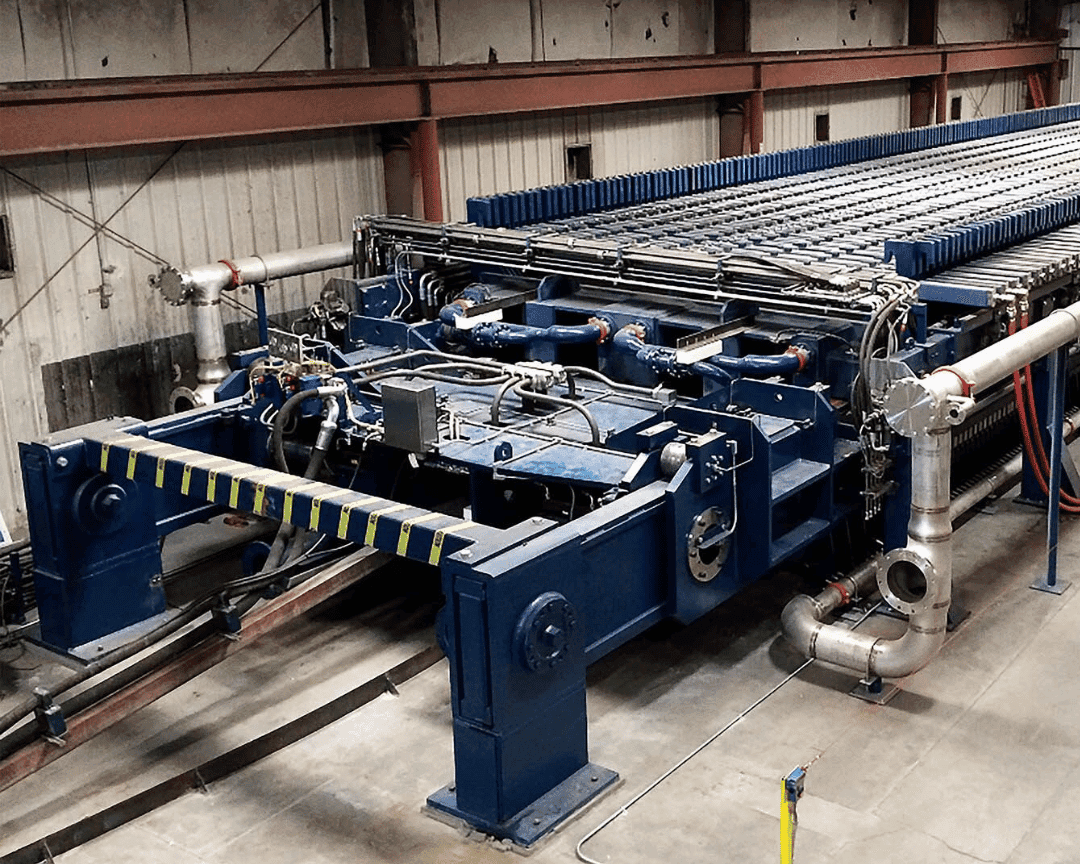

Rebuilding

Where filtration equipment has worn over time, we can bring it back to as-new condition with our rebuilds services. For example, drum filters are older filtration technology but are still widely used due to their simplicity of operation. Over time the mechanical condition of these drum filters deteriorates due to prolonged operation and cyclical forces impacting the machine. A rebuild of the drum filter main components improves reliability and efficiency of the vacuum system. Vacuum system improvements have the added benefit of reducing energy consumption and increasing filter performance. We have rebuilt drum filters in operation for decades, enabling mine operators to rejuvenate their filtration operation without the expense of buying new equipment.

Exchange

Our exchange programme enables you to immediately replace worn parts with as-new reconditioned components. We deliver the new parts to site and remove the worn equipment to our facilities for refurbishing. These renewed parts then become part of our exchange programme. This programme keeps costs down while also reducing the environmental impact of your process.