We’re here for you

Your mining partner on the ground

Unmatched expertise and capabilities

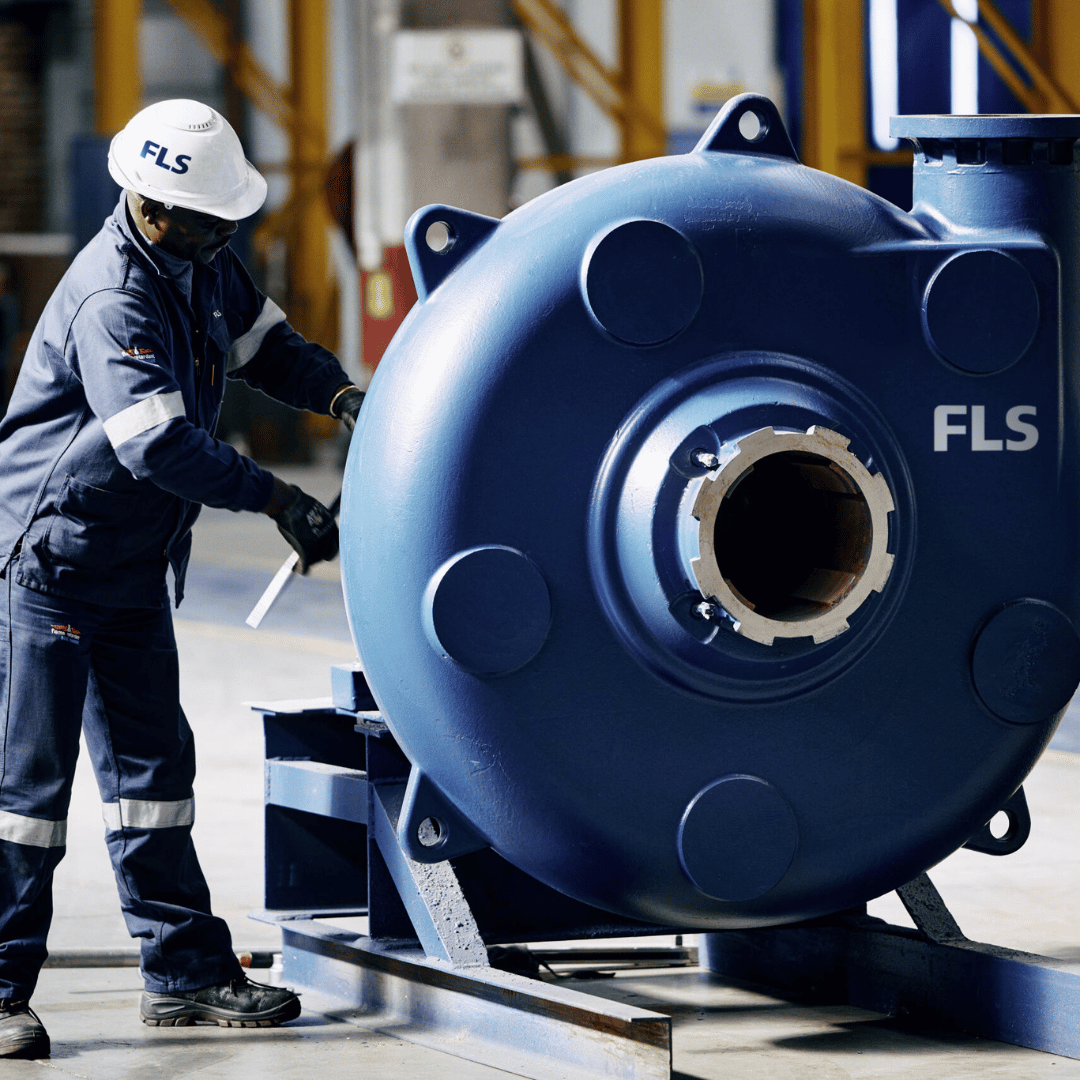

At FLS, we pride ourselves on being a trusted supplier, offering specialized professionals and services tailored to our customers' unique needs. Our full flowsheet lifecycle services, backed by extensive specialized knowledge, set us apart from competitors. Beyond maintenance and repairs, we provide comprehensive training and a well-stocked inventory of parts, ensuring top-notch expertise and support. Plus, we can partner with our customers to provide exchange programmes for key equipment to keep the operation up and running.

Minimise risks

By allowing FLS service centres to handle maintenance, mine sites can reduce safety hazards and improve employee competence. Our centers manage potentially dangerous maintenance activities and store essential spare parts to ensure equipment availability. Additionally, our training capabilities enhance operator knowledge and understanding of the equipment.

Reduce downtime and costs

Our strategically located regional service centre network provides local support, reducing transportation time and ensuring efficient maintenance. With all necessary tools and equipment on-site, our centers can involve specialists as needed and operate up to three shifts, speeding up repairs while maintaining high-quality workmanship. This approach reduces lead time, lowers OPEX costs during equipment downtime, and offsets transport costs by enabling earlier production restarts.

Find your local service centre

Our strategically located mining service centres are here to minimize downtime and maximize the productivity of your operations. Contact your nearest centre for prompt assistance tailored to your region's needs.

FLSmidth (Pty) Ltd.

- South Africa

- Service centre

P O Box 543 Maraisburg 1709

Reg. no. 9571029710

FLSmidth Inc.

- United States

- Service centre

P.O. Box 1108, Sioux City,

IA 51102

Reg. no. 23-0606560

FLSmidth Inc.

- United States

- Service centre

1315 N. Cullen Ave. Ste. 102, Evansville,

IN.

Reg. no. 23-0606560

Mining services for the full flowsheet

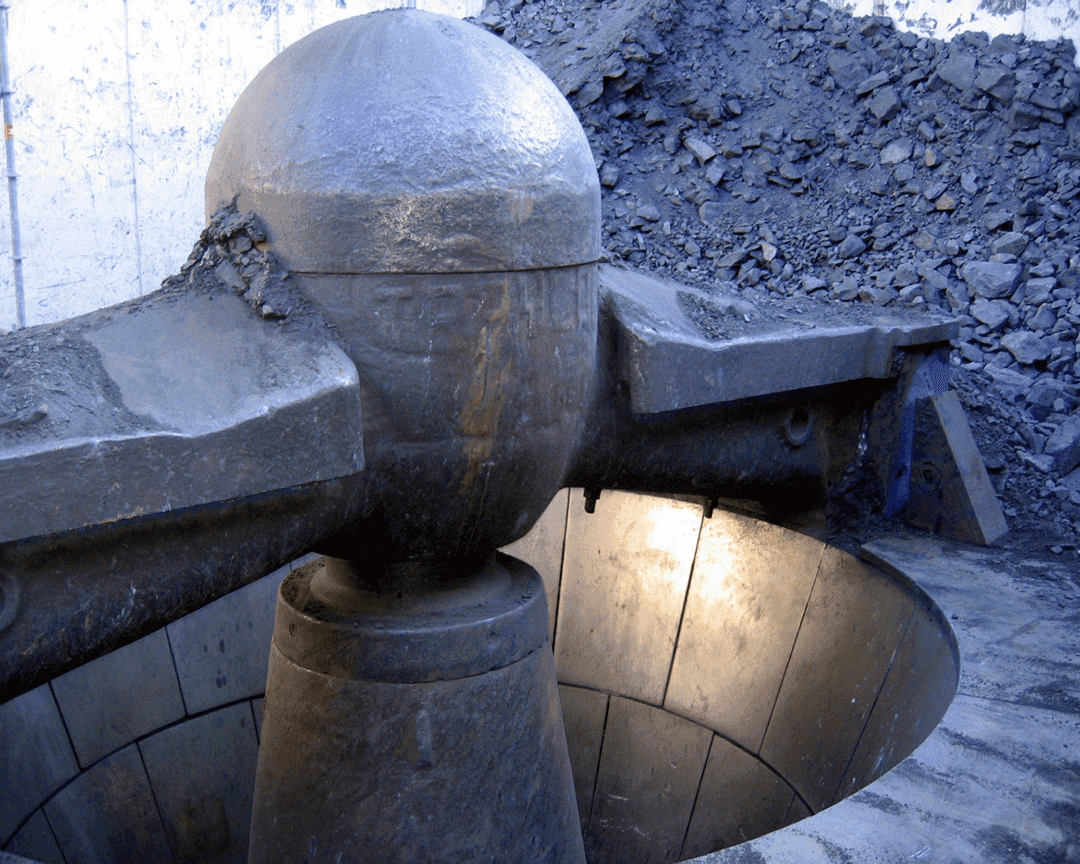

Supporting your crushers

Wear parts, rebuilds, maintenance and training are all part of our service centre capabilities.

Screening

Screen rebuilds and screening media can be accommodated through our regional service centres.

Milling

Whether it’s a roller rebuild, spare or wear parts, or troubleshooting, our service centres are equipped to support you.

Hydrocyclones

Wear parts, upgrades, rebuilds and exchanges are all part of the hydrocyclone offer from our service centres.

Flotation

Thinking about upgrading your flotation cells? We can support you. We’re also able to supply wear parts, carry out rebuilds, and offer field services and training.

FIltration

When it’s time to replace your filter media, call your local service centre for recommendations. We also offer drum filter rebuilds alongside other services.

Thickening

Maintenance, rebuilds, spare and wear parts are all part of the service on offer from your local technical service centre.