Compare SAG and AG mills – Design aspects

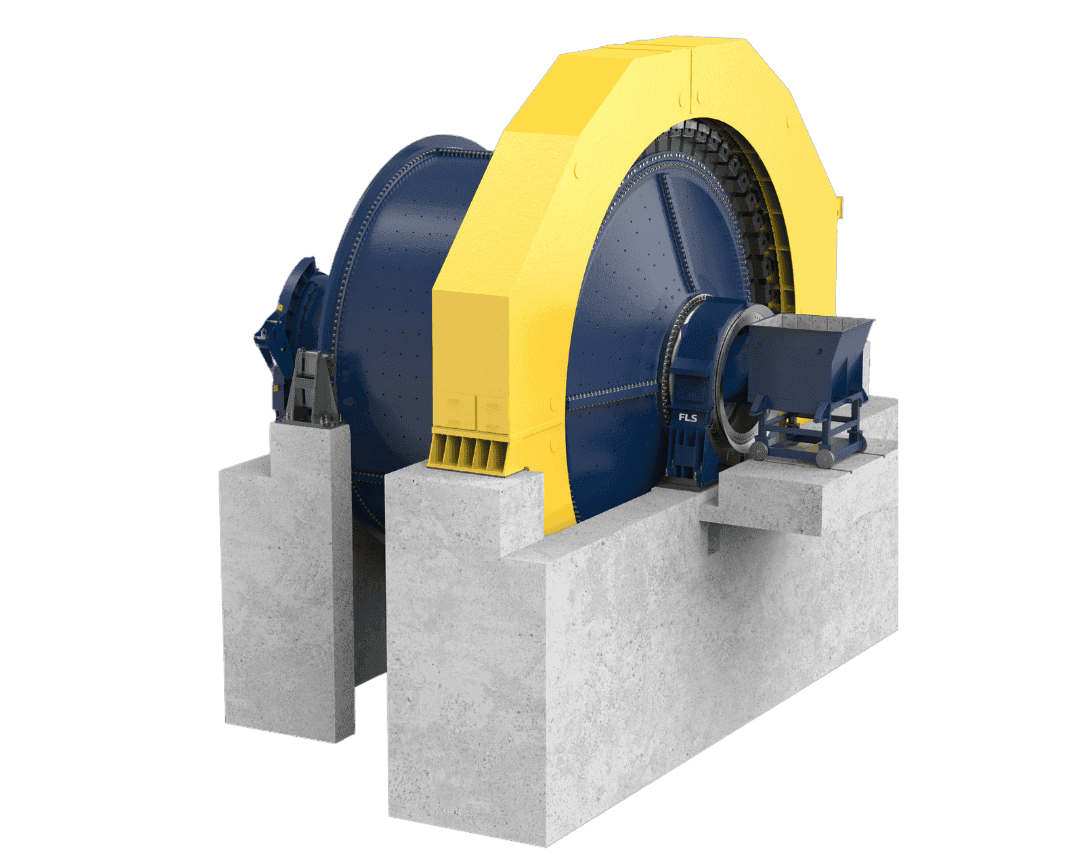

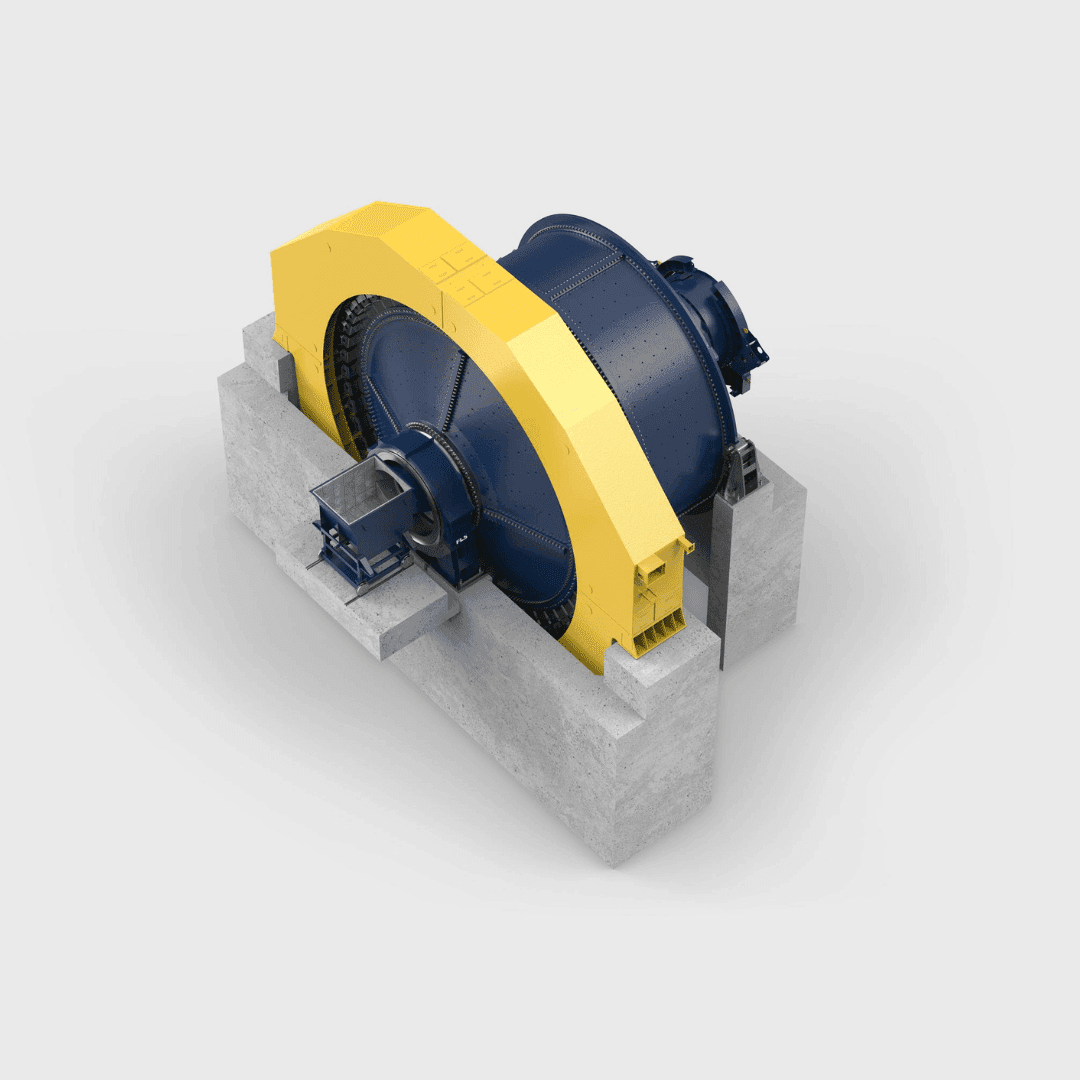

SAG and AG mills can be configured to suit the project demands with design features as follows:

- Support Method: Trunnion-supported or shell-supported

- Drive Train: High speed with reducer, low speed direct coupled, or gearless (wrap-around motor). Geared solutions can be single or dual pinion with references up to 10,000 kW per pinion.

- Main Bearings: Hydrostatic or hydrodynamic. Sleeve or multi-pad (self aligning).

Add-ons for SAG and AG mills

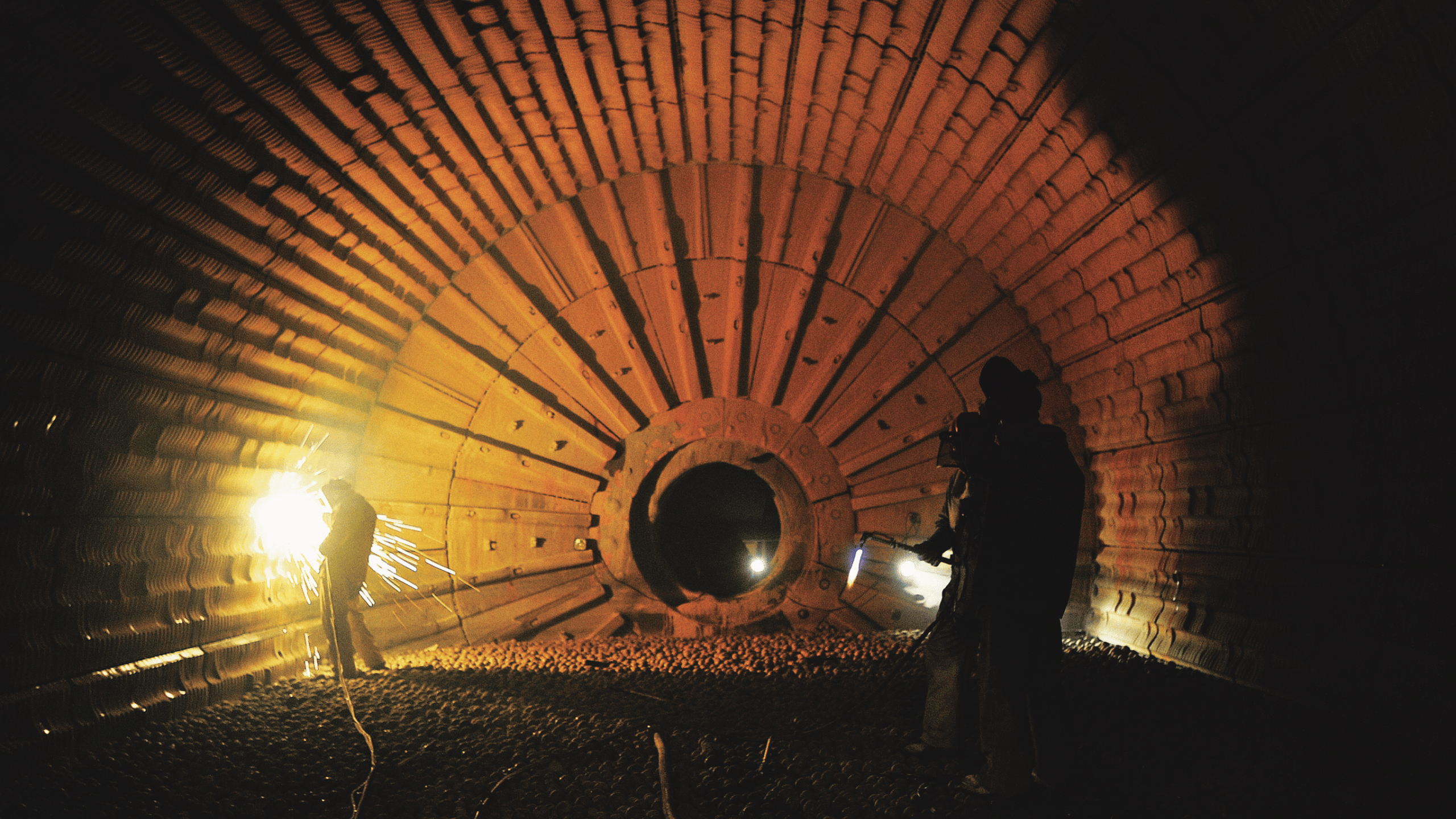

- Mill liners - Armour™ mill liners increase uptime and improve grinding efficiency

- LoadIQ™ – A smart tool to optimise AG and SAG mill loading to increase throughput by 3 – 6%

- Smart liner package – Extend liner life and reduce power consumption with a specialist package of lifecycle services

- ECS™/ProcessExpert – Optimise mill performance with our advanced process control system