Optimising efficiency with flotation wear components

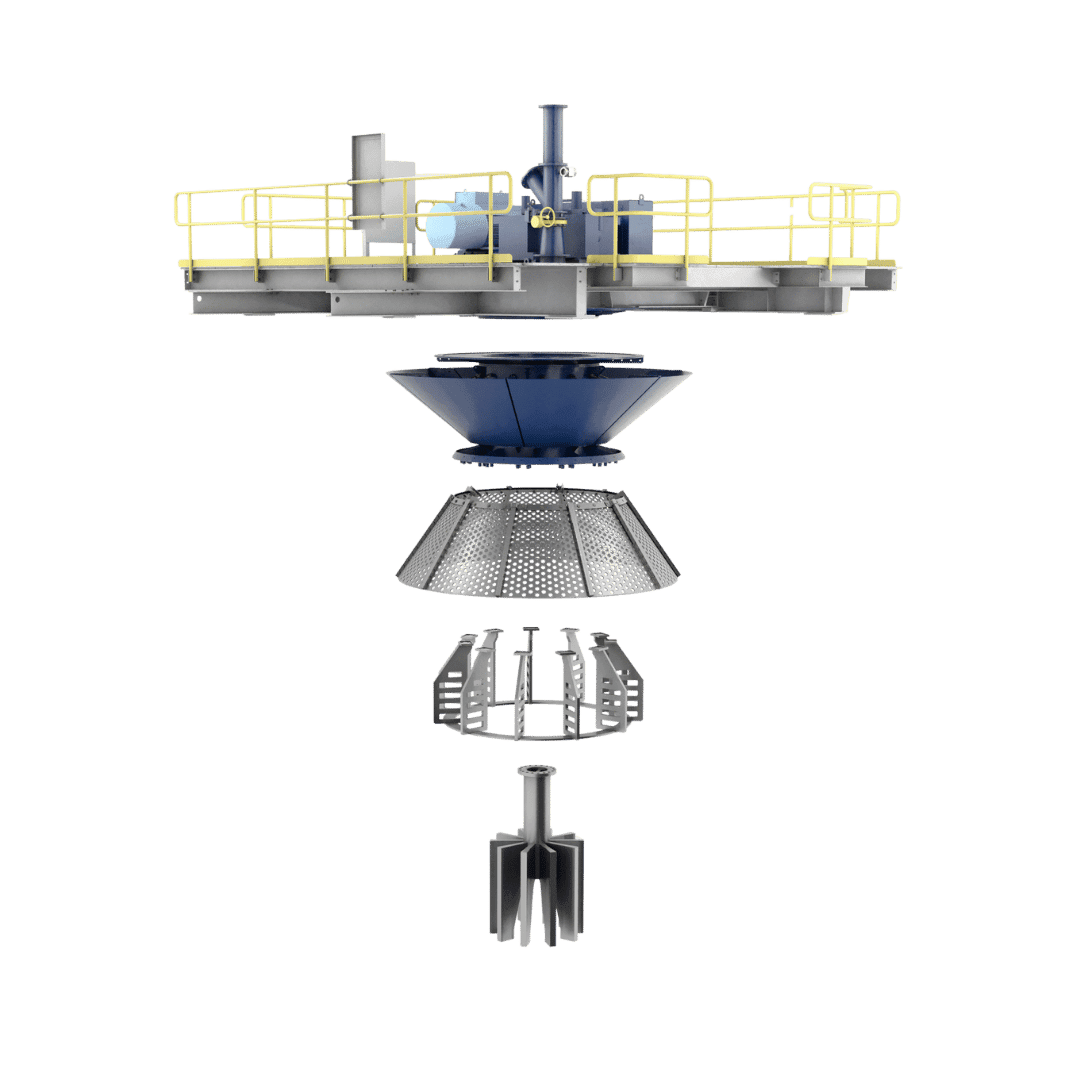

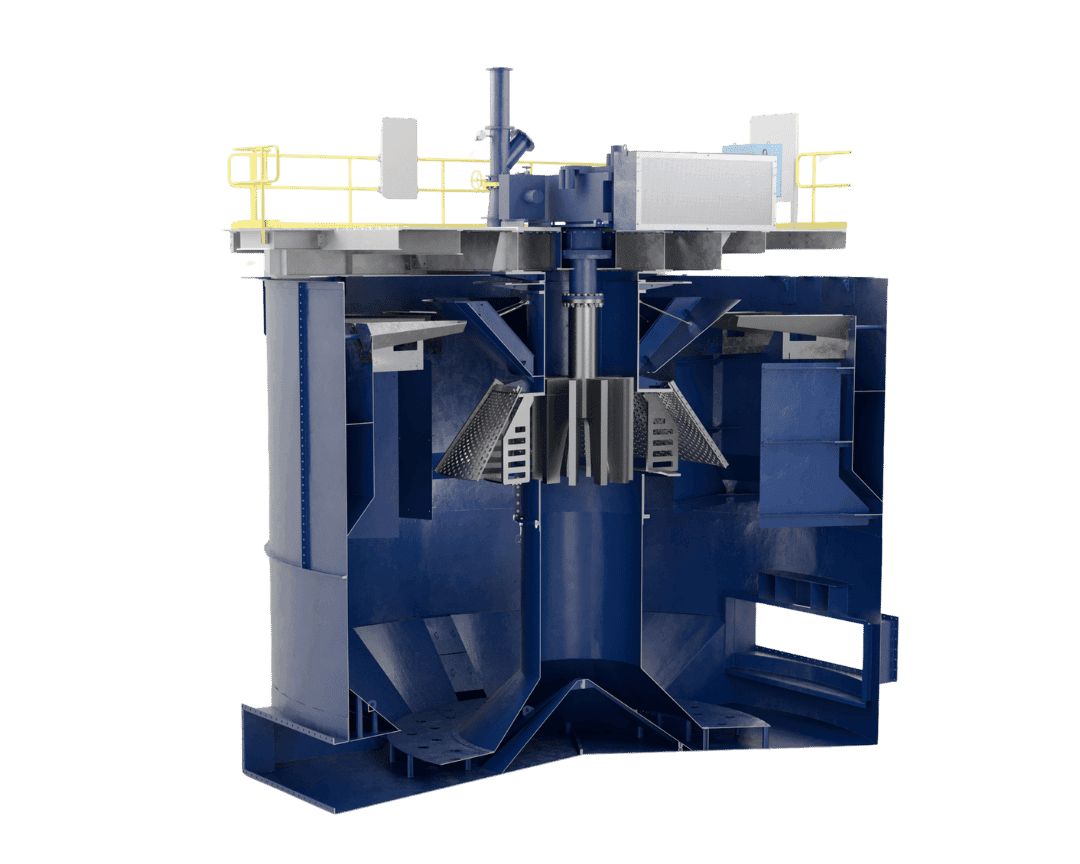

Choosing the best wear parts for your flotation circuit has multiple environmental benefits. First, longer lasting wear parts reduce waste. Second, wear parts that improve the performance of your flotation cell – such as the nextSTEP rotor/stator - reduce energy consumption and thus improve the carbon footprint of your process. Finally, more effective flotation creates a more sustainable downstream process by improving the efficiency of material recovery and reducing water waste.