High energy efficiency reduces operating costs

Our HPGR’s low energy consumption makes it a smart choice for miners looking to reduce their energy bills.

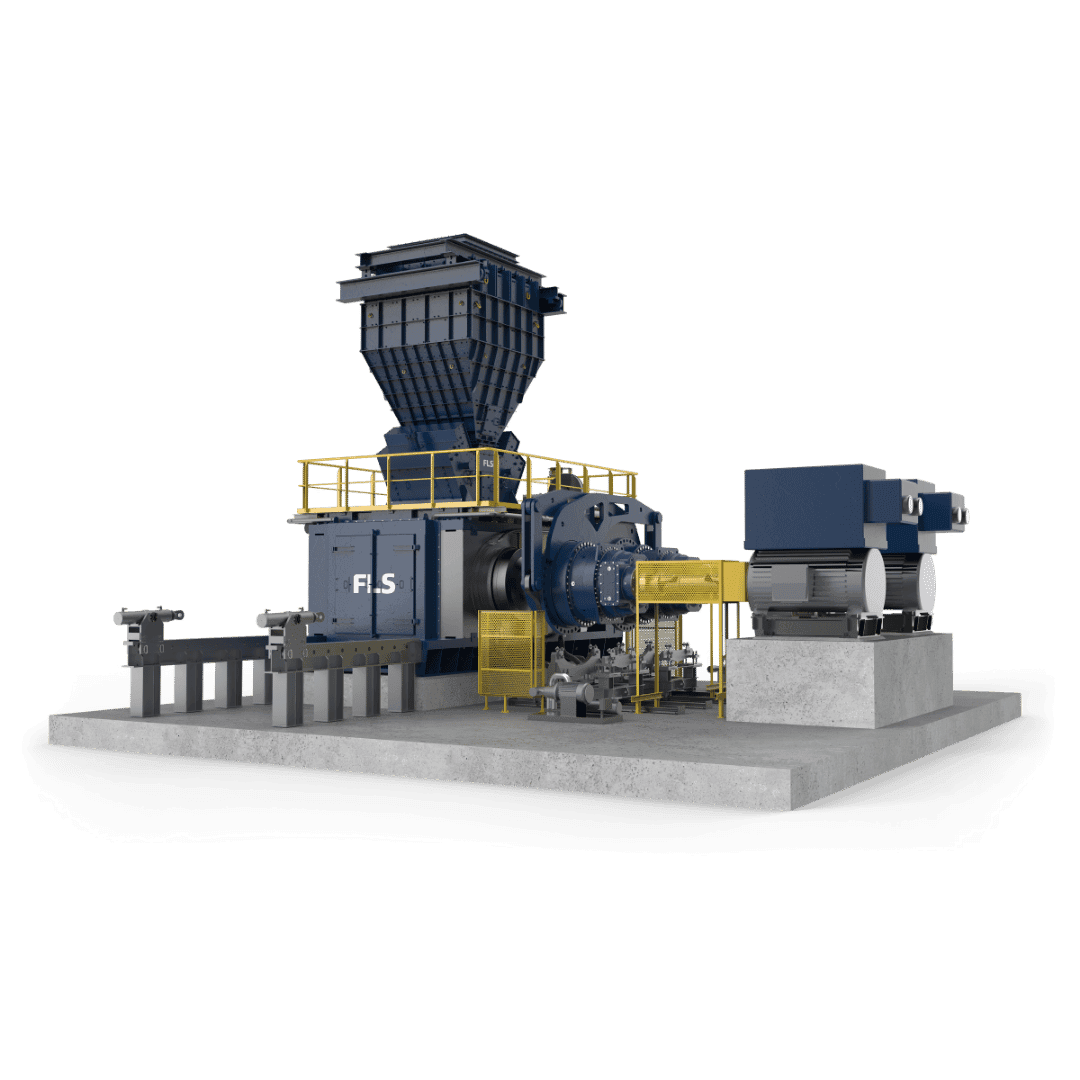

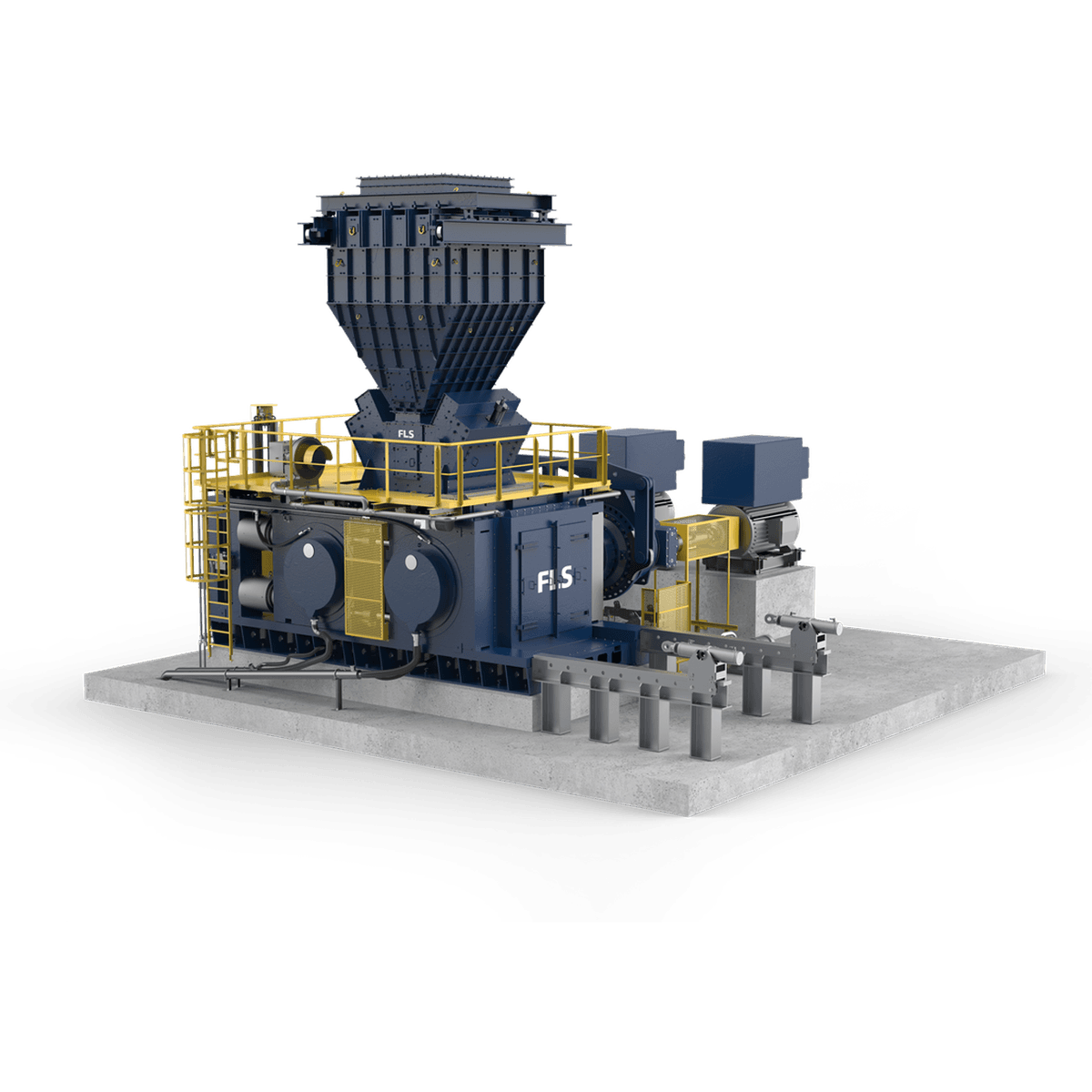

Optimise your results with a high pressure grinding roll, the most energy-efficient way to process mining ores. Suitable for industries including iron ore, precious metals, base metals and other, the HPGR’s ability to weaken rock structure provides metallurgical benefits downstream (i.e. enhanced kinetics for heap leaching).

Our HPGR’s low energy consumption makes it a smart choice for miners looking to reduce their energy bills.

The pressure of the HPGR’s grinding rolls causes microcracking in the materials, a highly effective and efficient means of grinding that enables increased throughput and productivity.

This microcracking further prepares the materials for subsequent processing and improves the efficiency of flotation or leaching. Thus, the HPGR doesn’t just make grinding more efficient – it improves the entire process.

The HPGR truly is a unique comminution product. It weakens rock structure and exposes ore particles, making it an attractive option for all applications. HPGRs add efficiency to the primary grinding circuit for highly competent and complex ore bodies. HPGR product has microcracked particles which weakens the boundaries and lowers the Bond work index. This reduces the amount of ball milling power required downstream. In addition, our HPGR offers:

The next evolutionary step in our market leading HPGR technology is the HPGR Pro. With next-gen features resulting in operational advantages, the HPGR Pro offers; higher throughput capacity, greater power efficiency, and longer wear life of the rolls compared to conventional HPGR.

All of our HPGR Standard models (machine sizes 4 thru 10) can be retrofitted with any (or all) of the Pro features to transform your existing HPGR into an HPGR Pro:

The rotating side-plates improve the material feed into the rolls. By eliminating the so-called “edge effect”, the rotating side-plates ensure a more finely ground product and lower recirculation. Compared to conventional HPGR, this increases the throughput, while reducing the machine’s specific energy consumption. The rotating side-plates also result in a more uniform pressure profile and more even wear across the entire width of the rolls. This significantly increases the rollers’ roll service life.

The controlled mechanical skew limiter, a unique feature of the HPGR Pro, uses a mechanical locking device to limit misalignment of the movable roll. This allows the rolls to adjust to differing feed conditions. In this way, the more uniform pressure profile made created by the rotating side-plates is maintained across the width of the roll face and does not deform, as is the case with a skew suppressor.

This controlled skew limitation prevents critical values from being exceeded, protecting the rotating side-plates from damage… even in case of an emergency or operational error. The result is:

Our unique laser stud detection system scans, measures and monitors the wear surfaces of rolls while in operation and the trending information is automatically stored. No more need to shut the HPGR down and access physically for taking manual measurements.

A local HMI panel is provided allowing maintenance personnel check the condition of the roll surfaces. The green/yellow/red color-coded “surface menu” displays the location(s) of possible defects on the roll surfaces.

The laser stud detection system not only detects missing or damaged studs and edge blocks but can help with scheduling roll change-out.

Lubricating the bearings with a constant flow of conditioned oil enables higher machine loads to be achieved. This also significantly lowers the operating temperature of the bearings and quickly removes any grit. All combine to maximize the service life of these critical components.

The oil is filtered and cleaned in a closed system, lowering lubricant consumption, which reduces operating costs as well as lowering the impact on the environment.

The Advanced machine protection system (AMPS) constantly monitors the mechanical loads on the machine and warns the operator if specific loads are approaching the maximum allowed values, thus giving the operator the opportunity to react specifically, to reduce these loads.

Improved control systems as a prerequisite for further market driven automation – Operational Optimization!

Designed for low power demand, helping reduce energy consumption by up to 15% while maintaining strong operational performance.

Mechanical skew limitation prevents excessive movement, reducing damage risk and supporting safer operation even during upset conditions.

Longer roll service life by up to 30%, supported by continual oil filtering that extends oil use, with key components suitable for recycling to reduce waste.

Optimised bearing seals, oil quality monitoring and continual filtering help reduce contamination and support cleaner operation.

HPGRs operate in dry or semi-dry conditions, greatly reducing water use in grinding.

FAQs for HPGR/HPGR Pro

In a HPGR the material is ground in the operating gap between to counter rotating rolls that are fed from above and a high pressure interparticle communication ensures a high product fineness.

The roll wear pattern will depend on the hardness and abrasiveness of the ore as well as the operating conditions and flowsheet configuration. Today roll lifetimes of about 8,000 – 20,000 h can be achieved in hard rock applications.

FLS is the leading supplier of HPGR`s with more than 160 units in Mining applications.

HPGR’s potential can be best realised when processing ores from either highly competent or highly variable deposits. The main reasons for selecting HPGRs over other technologies are their lower specific energy consumption, wear-material consumption, and reduced overall CO2 footprint.

Therefore, even low-grade hard ores can be treated very economically. In addition, HPGRs produce a very uniform product, providing more stable plant throughput and better metal recovery. HPGRs are preferred for use in greenfield installations and brownfield expansions in tertiary or quaternary crushing stages, or as pebble crushers in semi-autogenous grinding (SAG)–ball mill circuits. They are also used as the final grinding step in producing the required iron-ore concentrate fineness for producing pellets.

These HPGR advantages, combined with continuous development and optimization of the roll wear-protection, have contributed to a rapid increase in the number of machines installed worldwide over the last 15 years.

HPGR and SAG mills use a different method of grinding. HPGR is a dry process grinding mill, while SAG mills are wet. SAG mills are a type of ball mill – a horizontal mill – whereas HPGR use rollers.