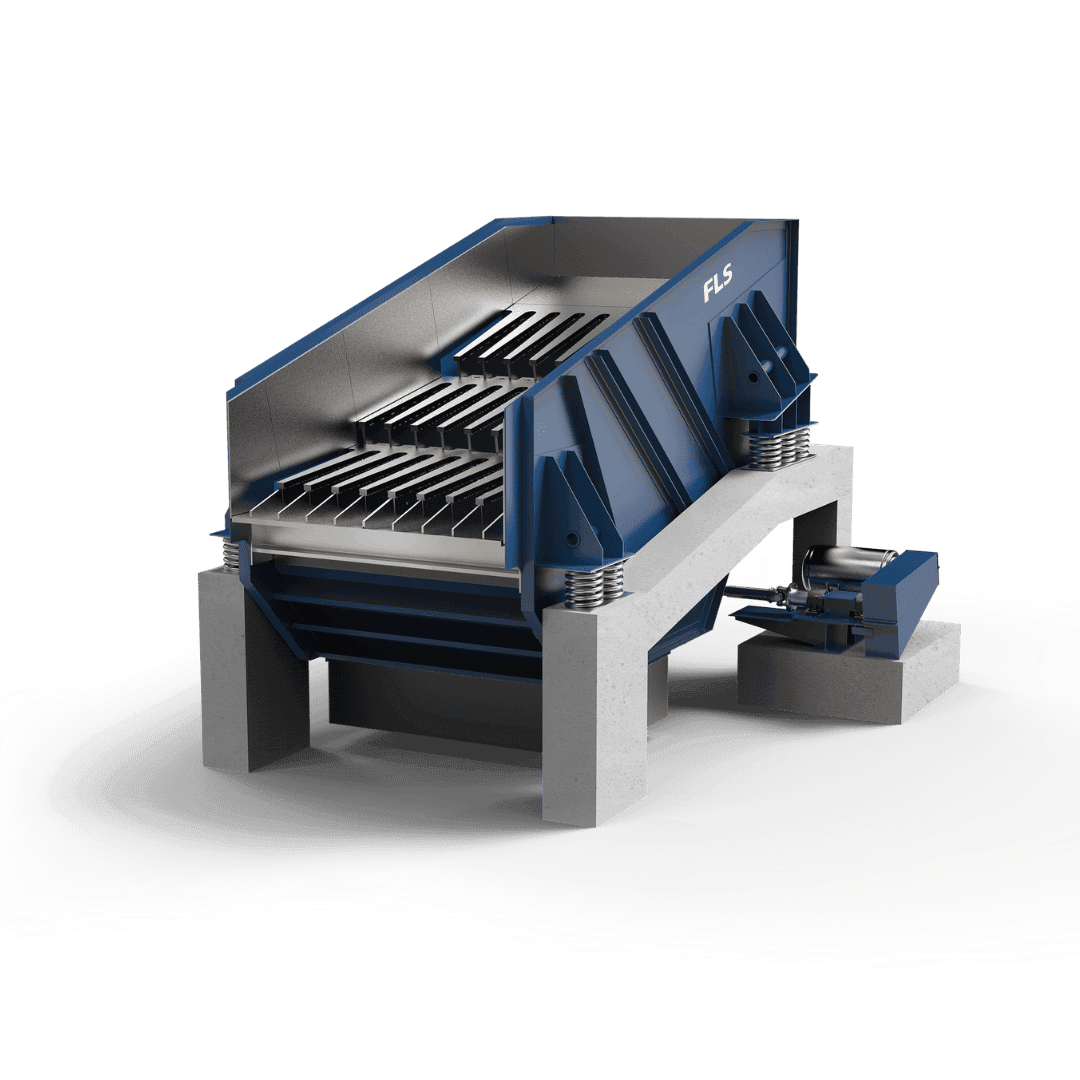

Robust, heavy-duty design

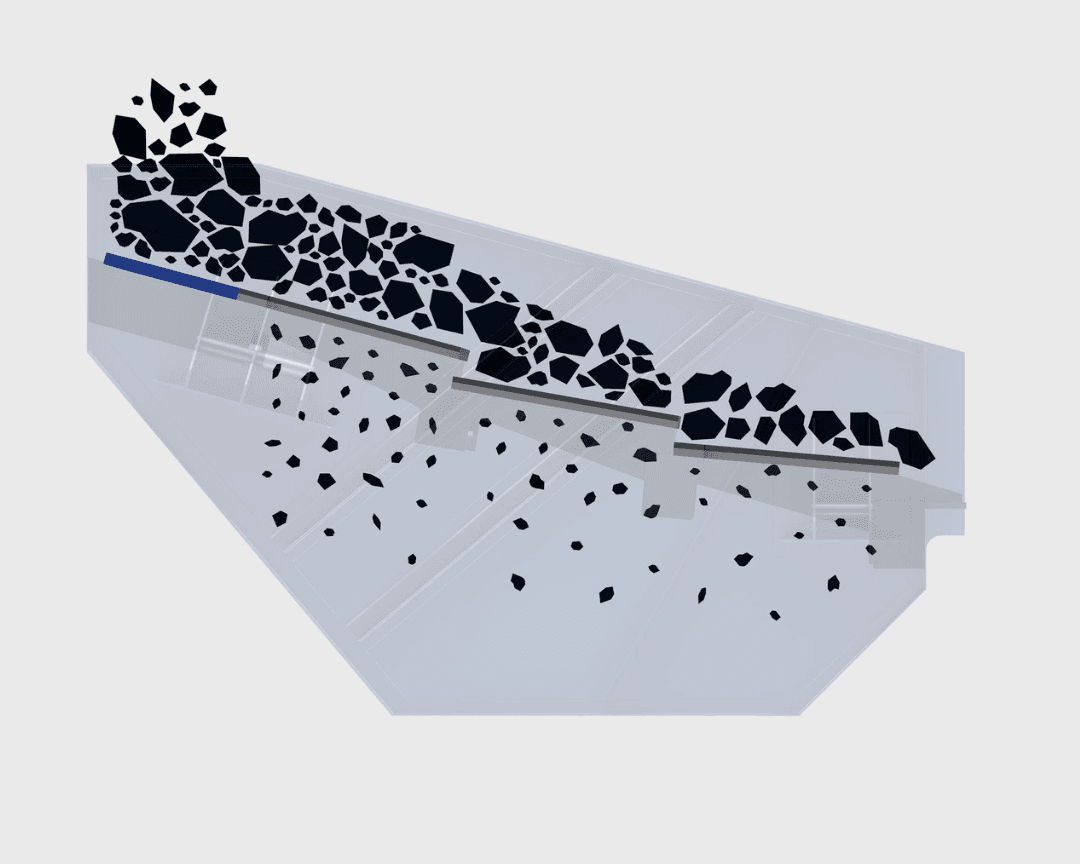

Our vibrating grizzly feeders handle high impact loads and g-forces. Notable features include sidewalls made from seamless plates, ensuring stress-free assembly. The machine’s cross beams are welded and stress-relieved while the grizzly cassettes are also welded with replaceable tapered wear plates. Heavy-duty springs ensure vibration-free operation and absorb shock loads. High wear-resistance grizzly bars or fingers are available for difficult-to-screen materials, offering maximum screen deck lifetime.