Validate screening performance without shutting down

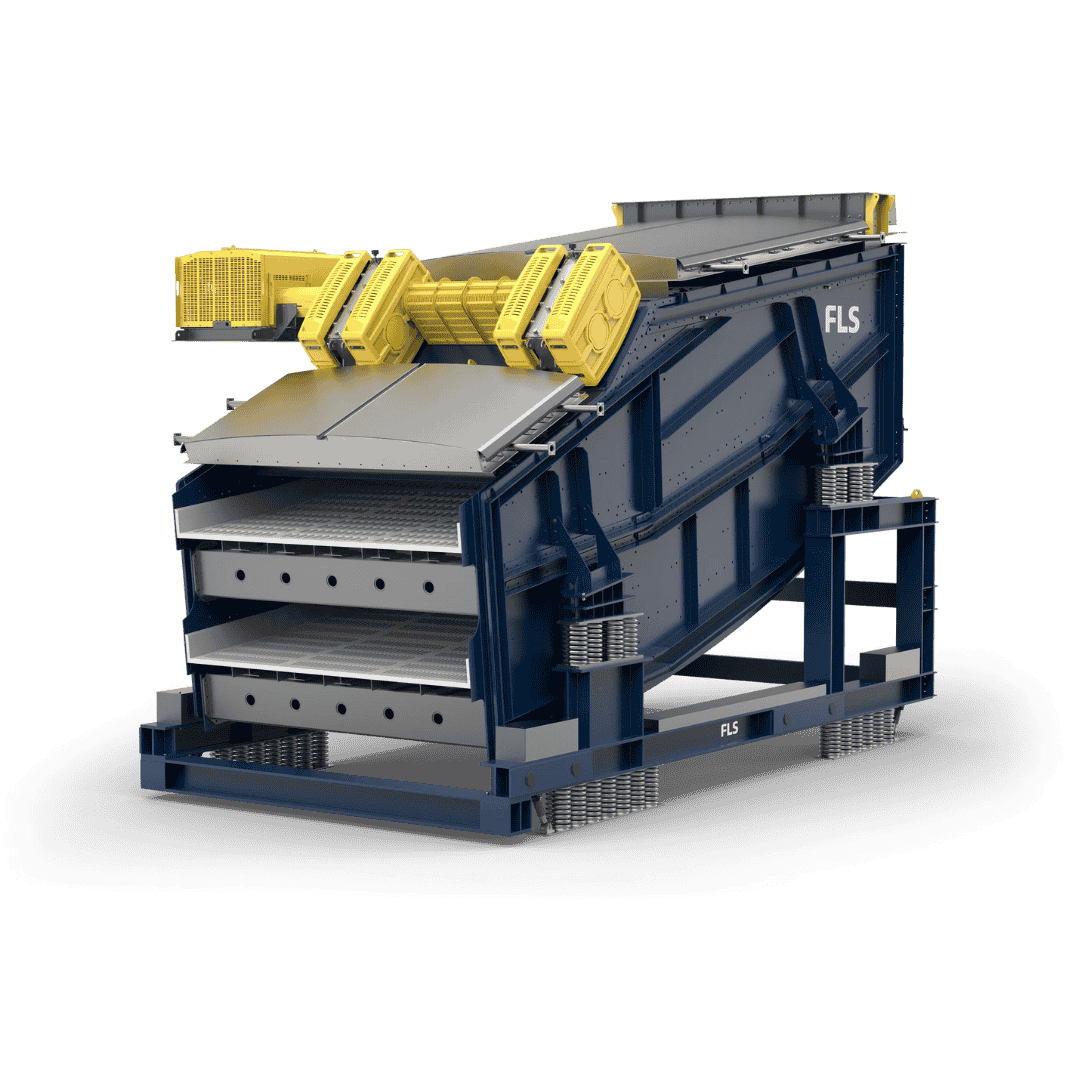

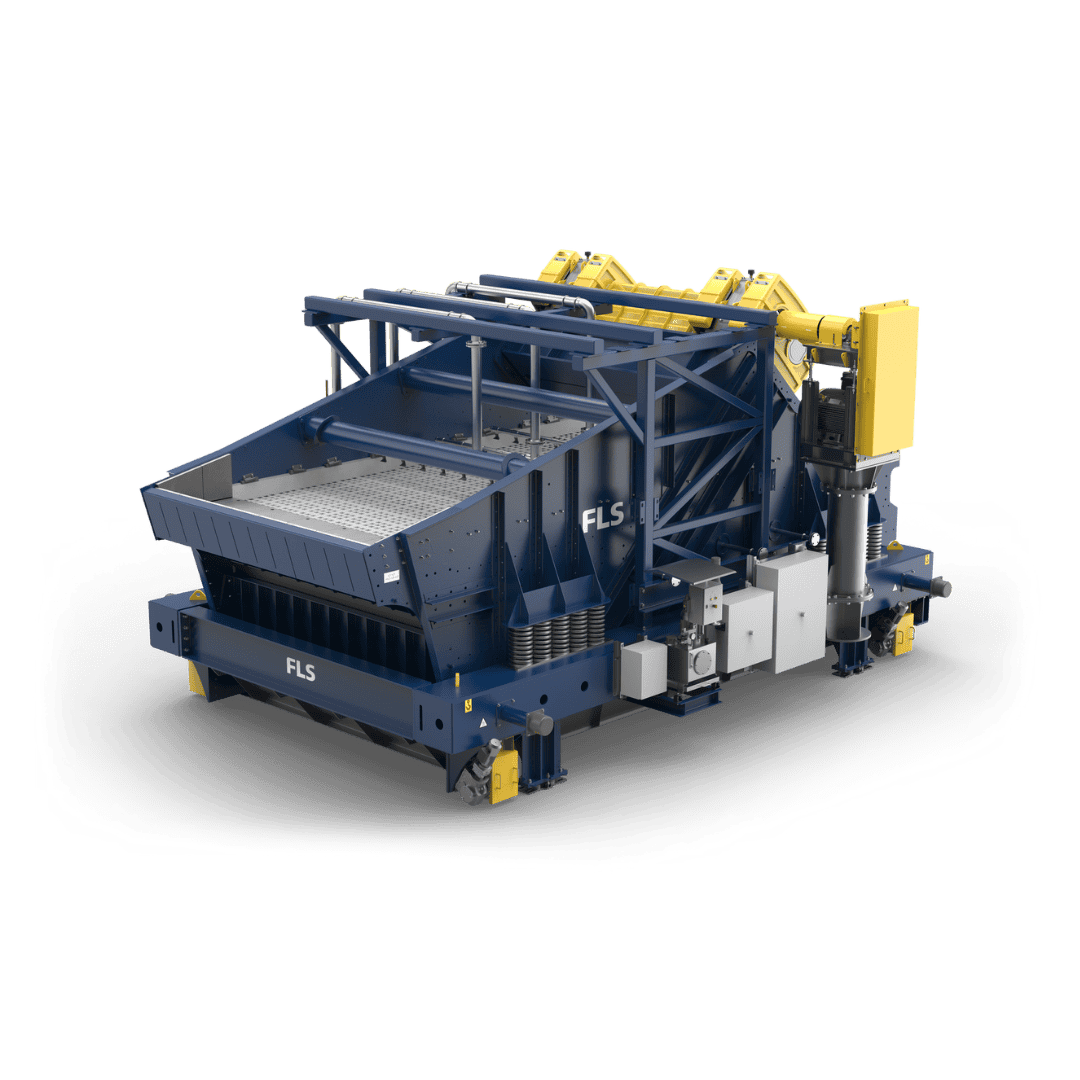

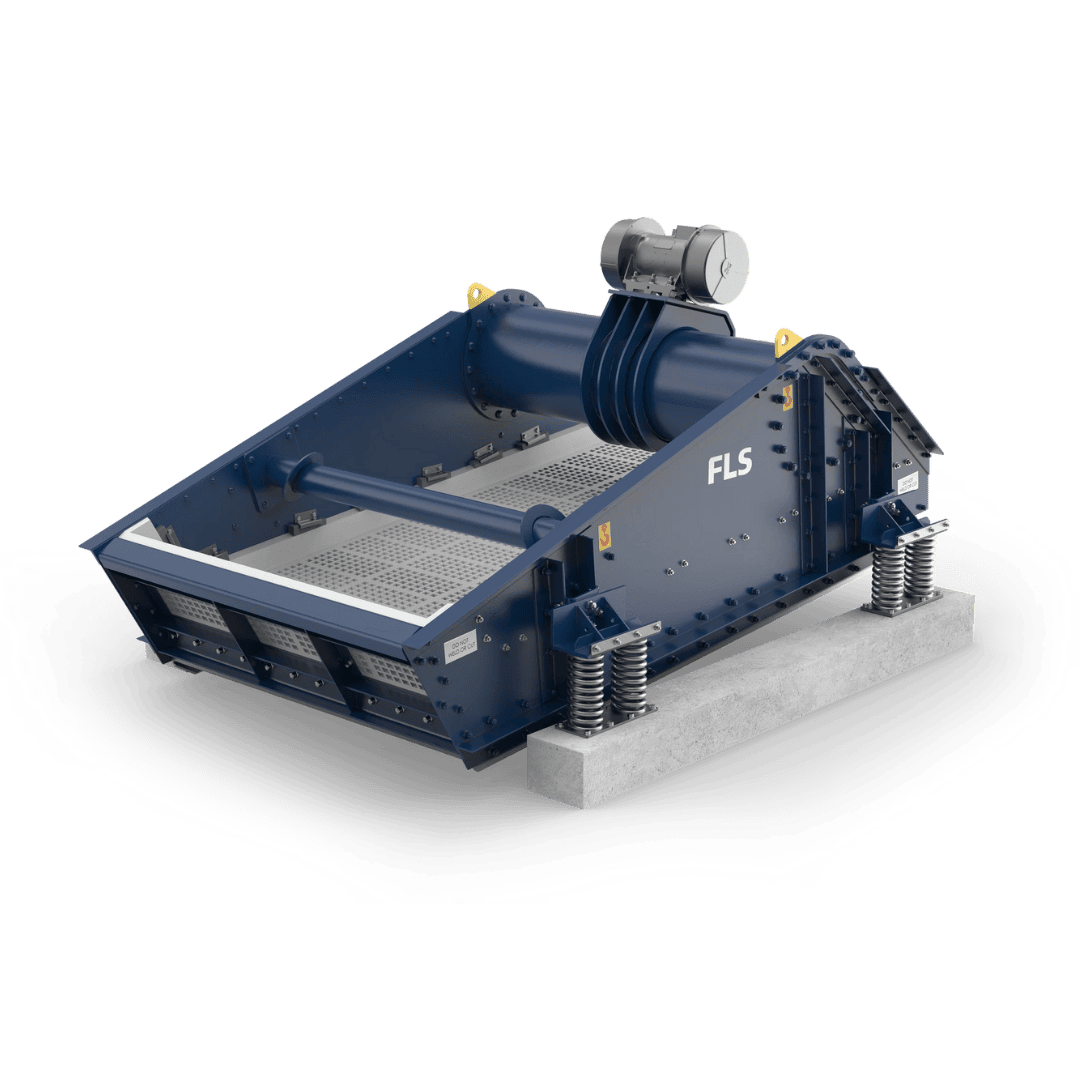

Screening AssetHealth is our onsite diagnostic service that analyses screen performance, identifies potential issues early, and delivers actionable insights to protect availability and optimise efficiency. Using the portable Screen Motion Analyser (SMA), FLS screening experts assess vibration, stroke, frequency, acceleration, and lateral displacement during regular operation—providing same-day clarity on how well each screen is performing and where interventions will deliver the most impact.

The service flags risks before they become failures: misalignment, exciter degradation, incorrect motion profiles, and wear patterns that threaten component life or compromise cut-size accuracy. With a clear action plan in hand, operators can schedule maintenance during planned outages, avoid costly unplanned stoppages, and extend the working life of critical assets.

Screening AssetHealth integrates seamlessly with FLS online condition monitoring, enabling trend analysis over time and continuous improvement cycles. Whether you're benchmarking existing screens, validating the impact of upgrades, or commissioning new installations, regular Screen AssetHealth assessments keep screening efficiency high and total cost per tonne low.