Our gyratory crushers

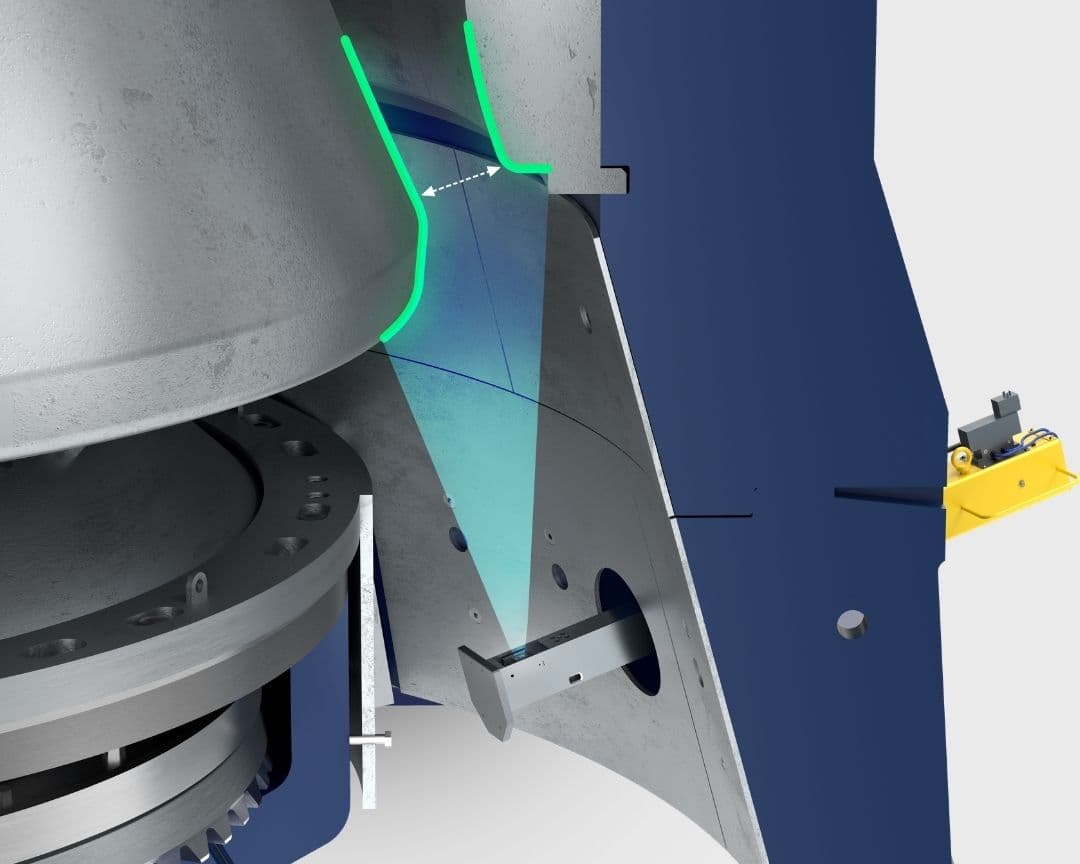

TSUV Gyratory crusher

The TSUV (Top Service Ultra-Velocity) gyratory crusher is our latest gyratory crusher. Designed for high capacity and performance, the TSUV has integrated Smart controls, like wear compensation and automatic mantle adjustment to maximise crushing efficiency. This latest generation builds on the strengths of earlier TS models to deliver increased speed, more power, and even easier maintenance. With capacities up to 15 000 tph, the TSUV is an ideal primary gyratory crusher and is also suitable for mining operations that require high throughput in their secondary crushing operations.

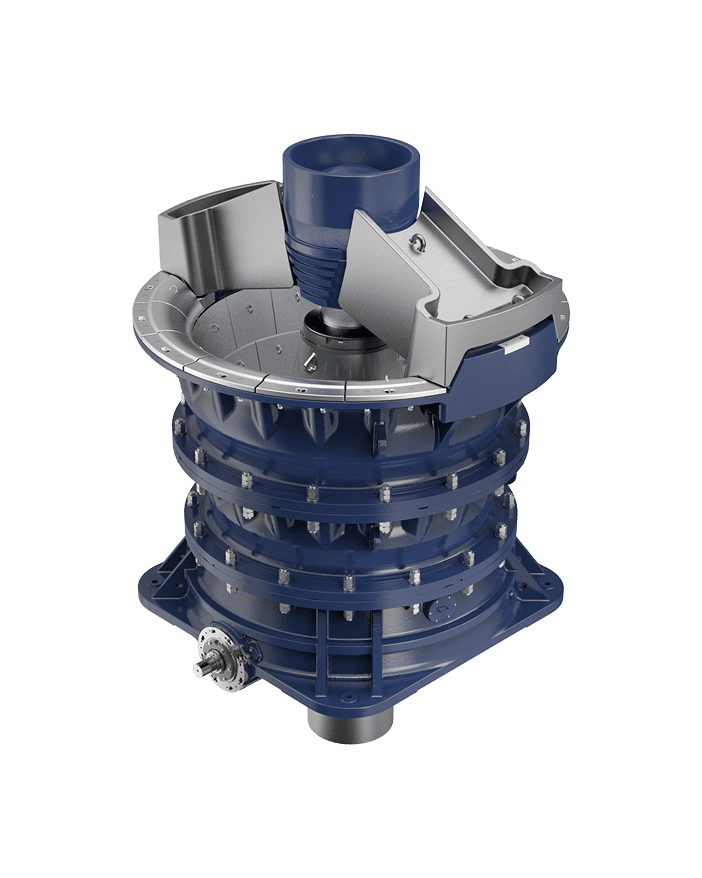

TS Gyratory Crusher

With a high quality, modern design, this durable gyratory crusher – the first in our Top Service line – was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projects. Easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher for simpler, safer maintenance, reducing downtime and maximising productivity. The TS Gyratory Crusher is in use across the world in hard rock mining applications.

NT Gyratory Crusher

The NT Gyratory Crusher expands on the success of Fuller’s TC line, keeping all of the good stuff – the Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components – and adding in more maintenance-friendly features for smoother, safer shutdowns. High motor power and matching drivetrain enable you to achieve heavy-duty crushing without moving into a larger sized crusher, keeping your crushing footprint down.

Gyratory Crusher Pro

The Gyratory Crusher Pro can handle up to 14 000 tph of hard rock in the toughest conditions – whether that’s the height of Australian summer or the depths of Norwegian winter. Built for ultimate performance and easy maintenance, this hard rock crusher excels at the crushing of medium hard to hard rock and ore in semi-mobile and stationary processing plants in ore mines and in the natural rock industry.