Why recovery matters

Mining’s environmental footprint is under increasing scrutiny. At the same time, the industry is tasked with supplying a growing demand for mineral products as cost-effectively as possible to support ongoing economic and demographic growth, urbanisation, industrialisation, and the green transition. Each tonne of recovered ore thus represents missed opportunities to benefit a mining company’s financial and environmental bottom line.

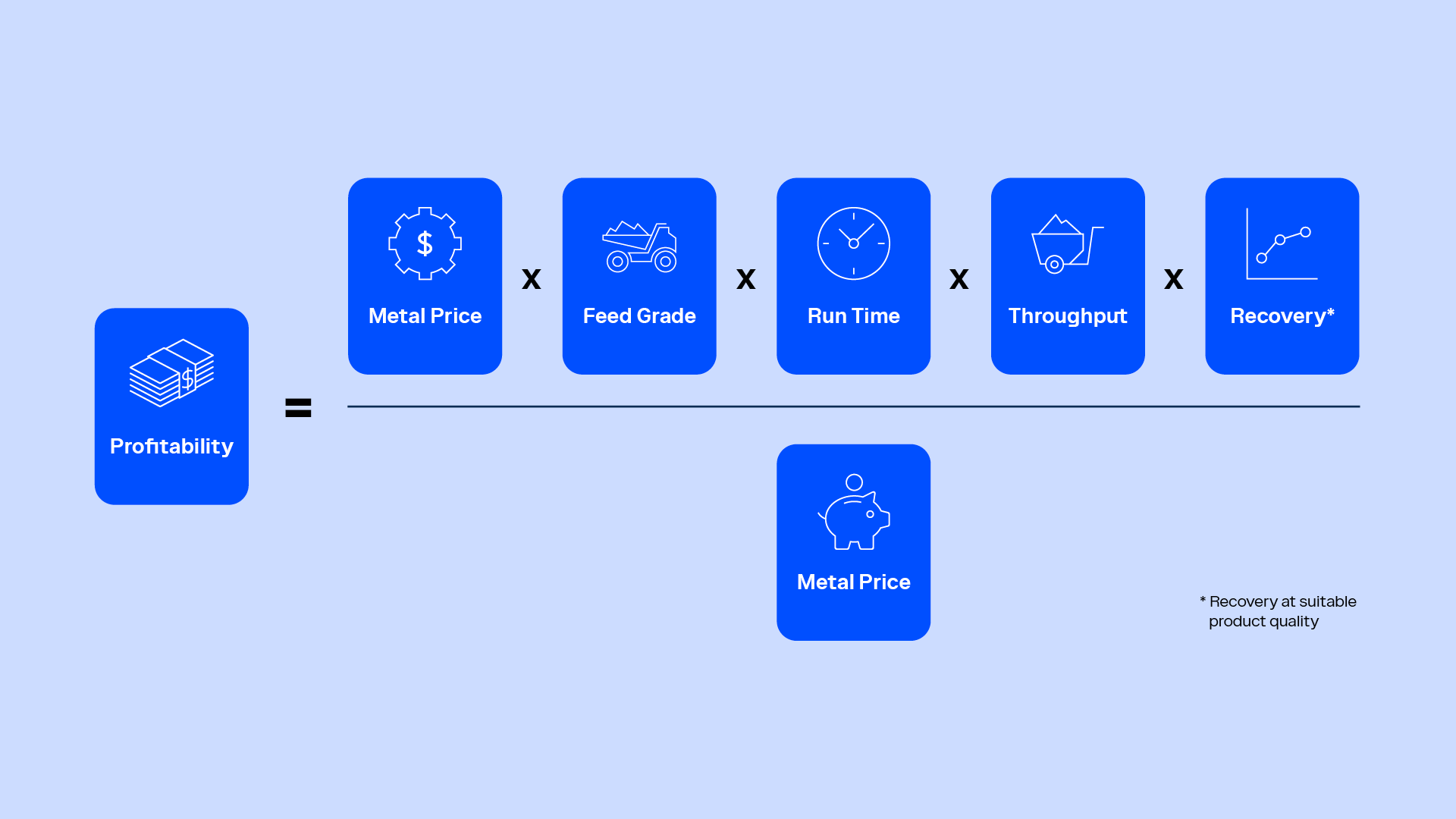

The impact of the recovery rate on profitability is an example. Profitability is a product of various factors within and outside a mining company’s control (Figure 1). Of those factors that are under a mining company’s control, run time and throughput are often constrained by factors outside the mineral processing plant fence (e.g., the number of hours in a day, upstream extraction activities) or inherent to the existing equipment (e.g., capacity, particularly of the mill, maintenance concerns).

Recovery optimisation offers a chance to boost saleable product without necessarily raising throughput or equipment run time and often while reducing operating costs. It can also frequently be done by upgrading existing equipment to avoid significant CAPEX. It thus directly impacts profitability as material previously lost is sold as metaphorical (or sometimes literal) gold.