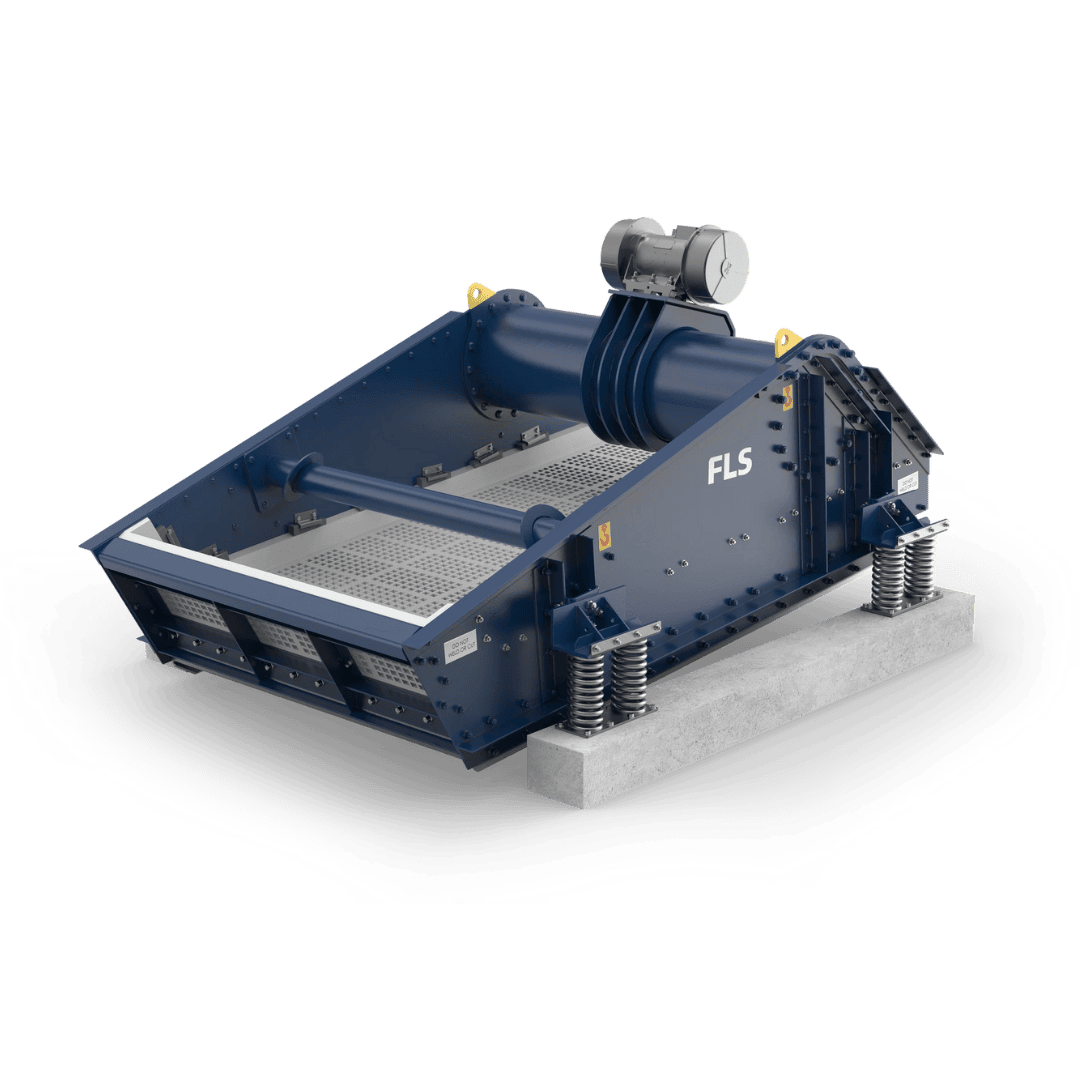

Bespoke design secures increased uptime

We know frequent shutdowns take their toll on your bottom line. That's why we work with you to understand the specific demands of your application and design a solution that will withstand the pressures of your operation to maximise uptime. Our materials and process experts will take into account your processing stage, ore, and production goals and match them to the optimum screening media, aperture design and fastening type.