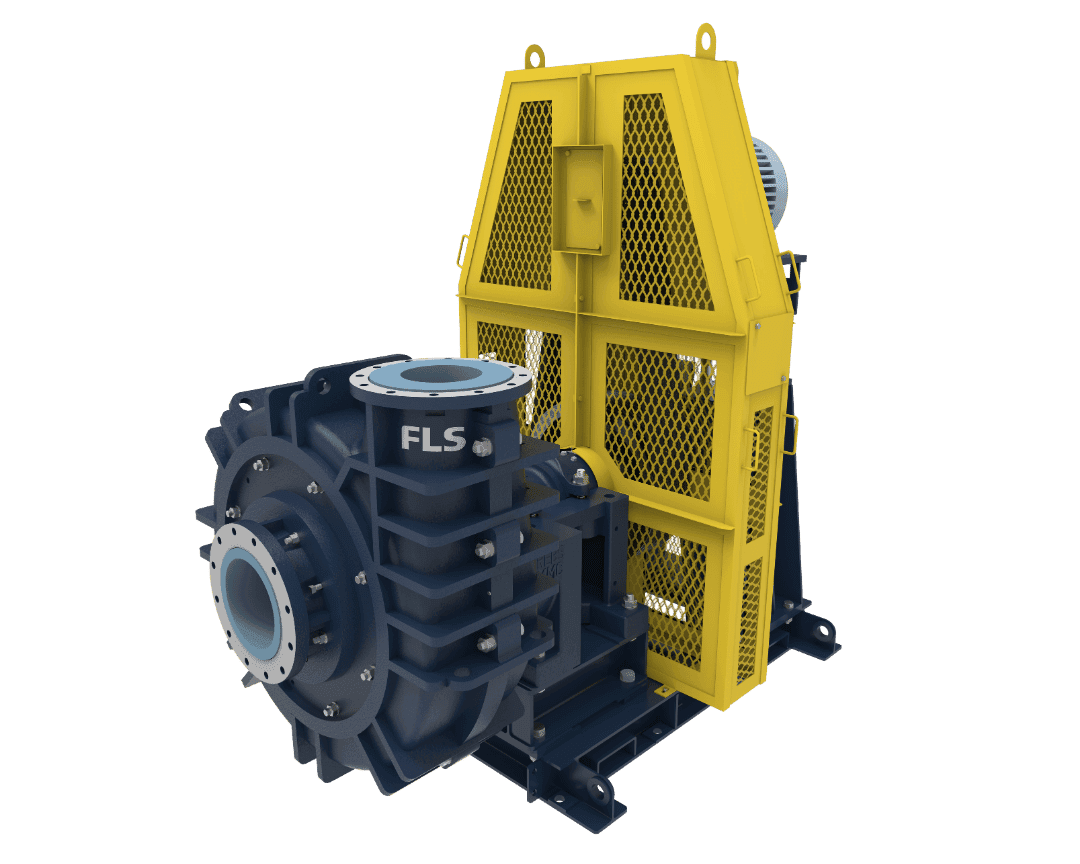

Maximise energy savings

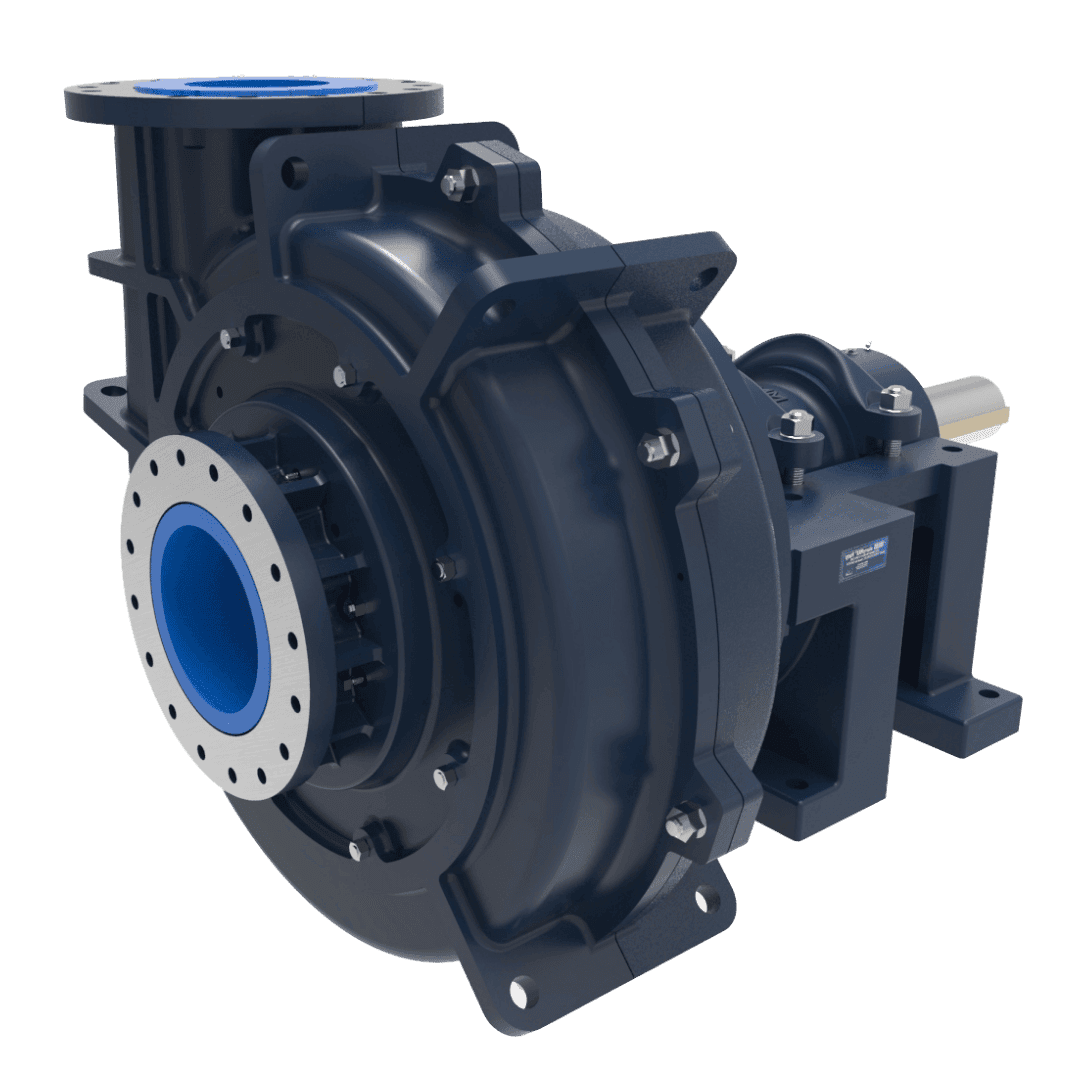

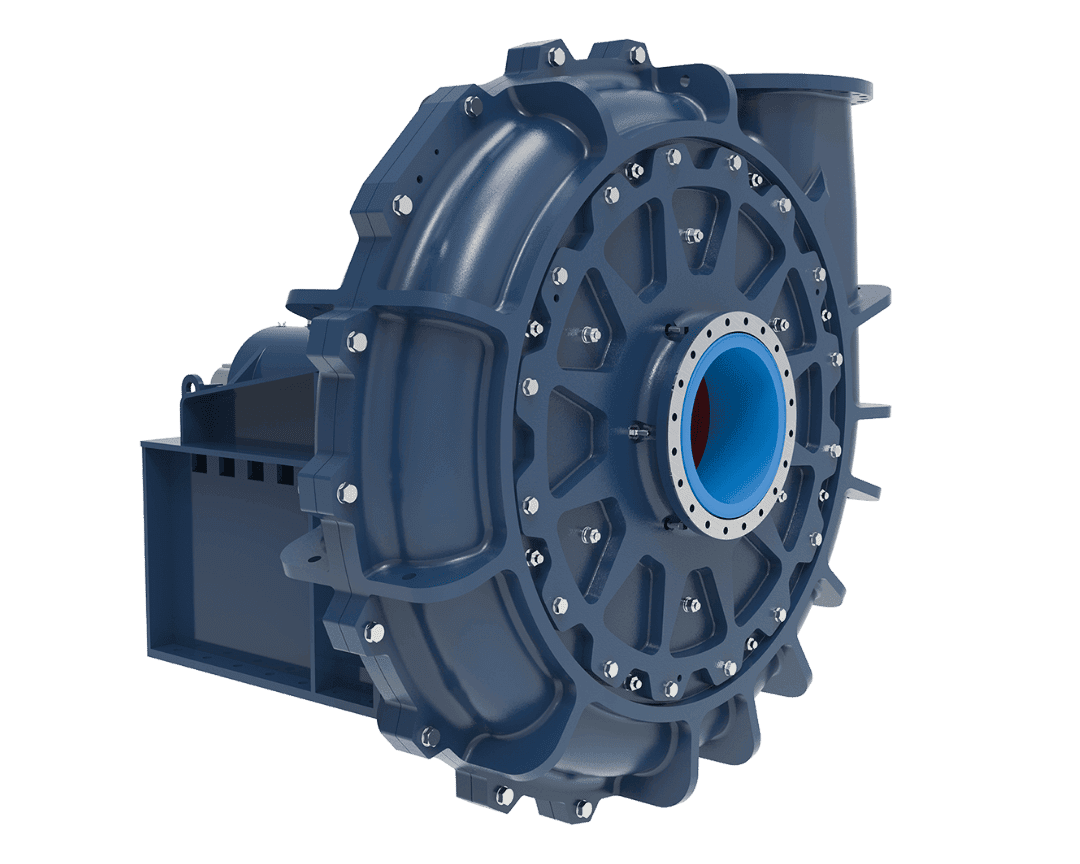

Our proprietary adjustable wear ring technology allows quick and easy control of suction-side clearance, increasing pump efficiency by 5-10% and helping maintain design performance over the pump's life, without increasing pump speed. This results in lower power consumption and lower cost per tonne pumped.