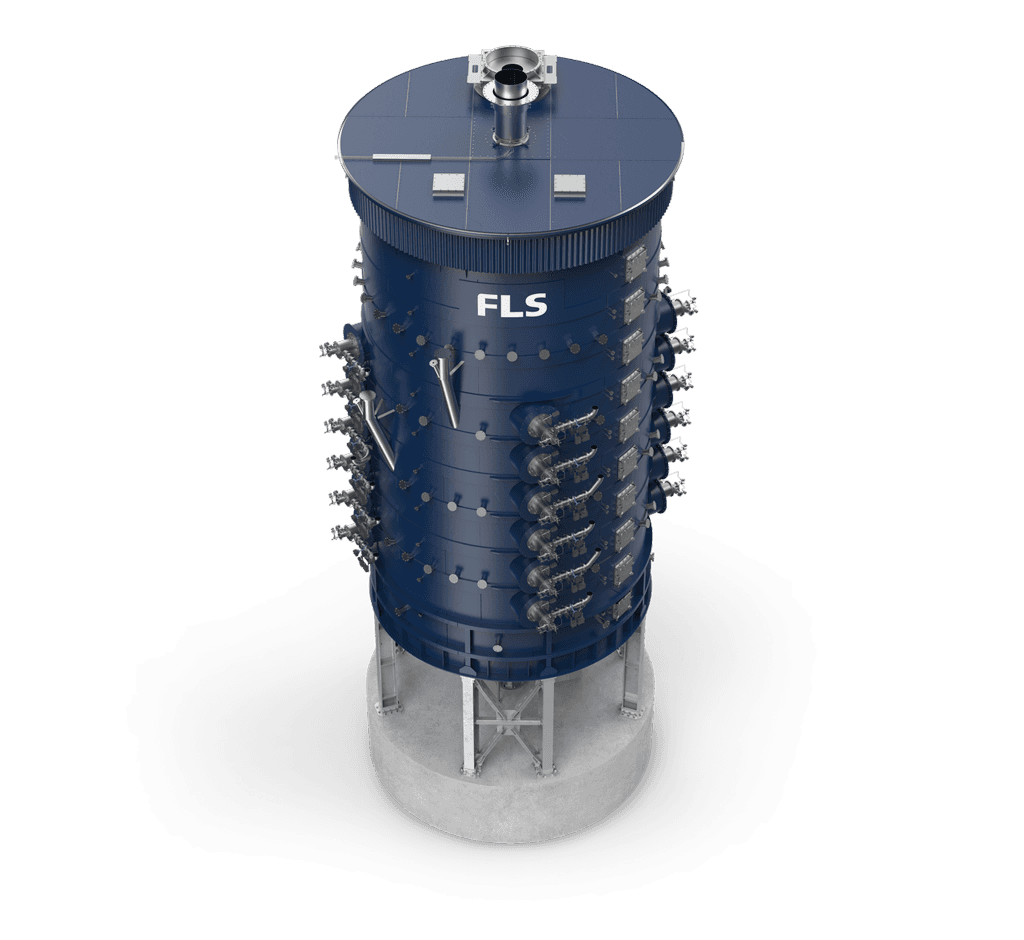

Our multiple hearth furnace

The multiple hearth furnace is a reliable and versatile technology with over 70 different applications, including calcining industrial minerals, flotation concentrates and filter cakes, thermally treating ores, biomass, and electronic scrap, and producing and reactivating activated carbon. Its multiple stacked hearths create different zones within the cylindrical furnace, each fulfilling a different purpose: from drying and heating through to calcination or oxidisation. Design parameters vary widely according to the specific applications. Systems delivered have included six to 19 hearths, diameters of 4.5m to 7.8m, and operating temperatures up to 1150°C. MHF can also use a variety of liquid and gaseous fuels, including low-calorific gas, and low-carbon alternatives such as hydrogen and electric heating.