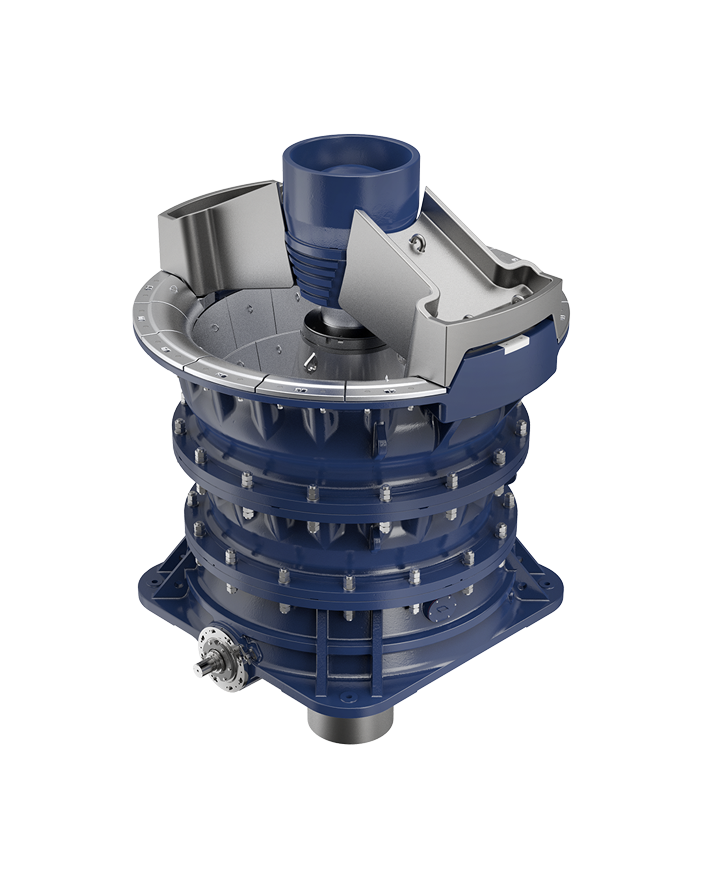

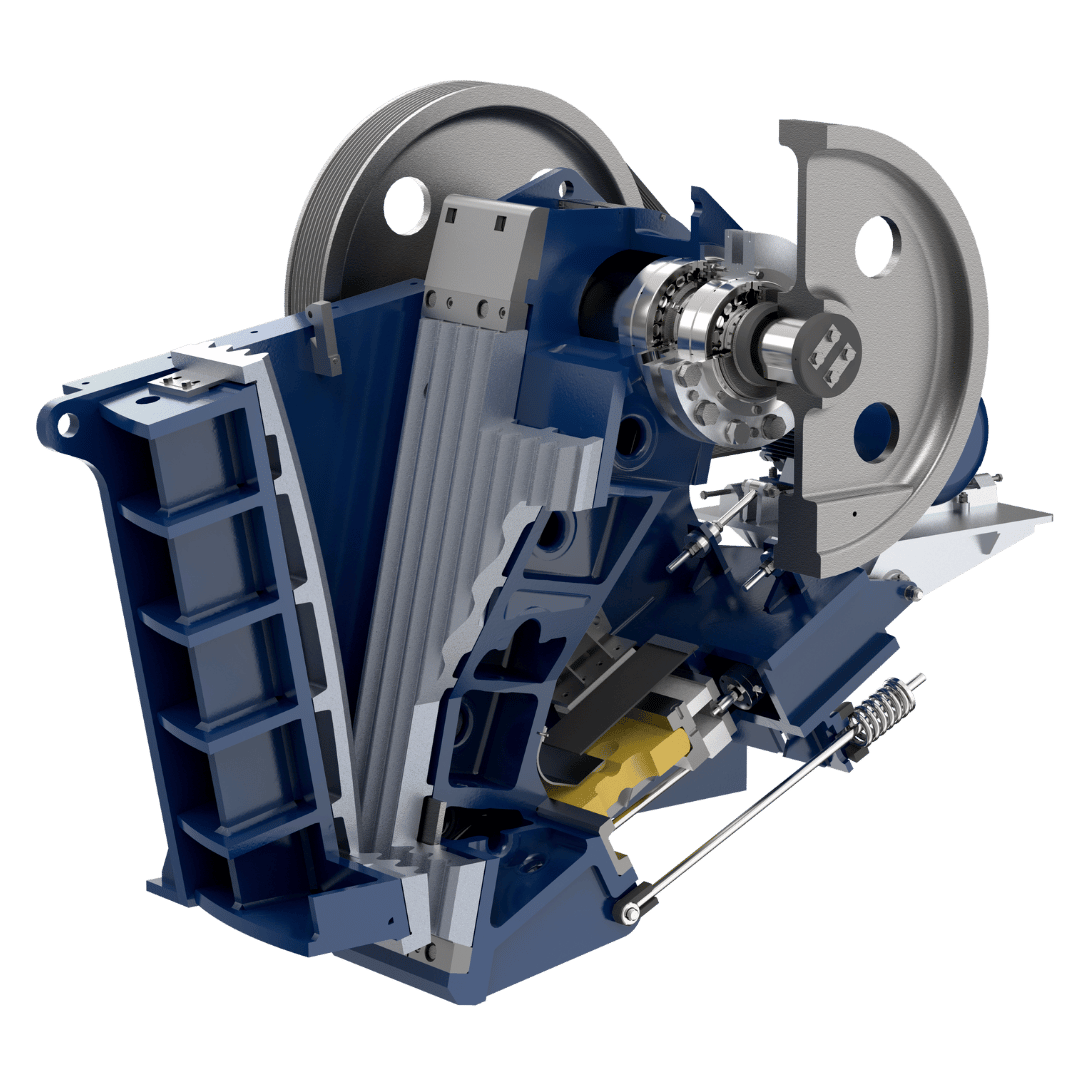

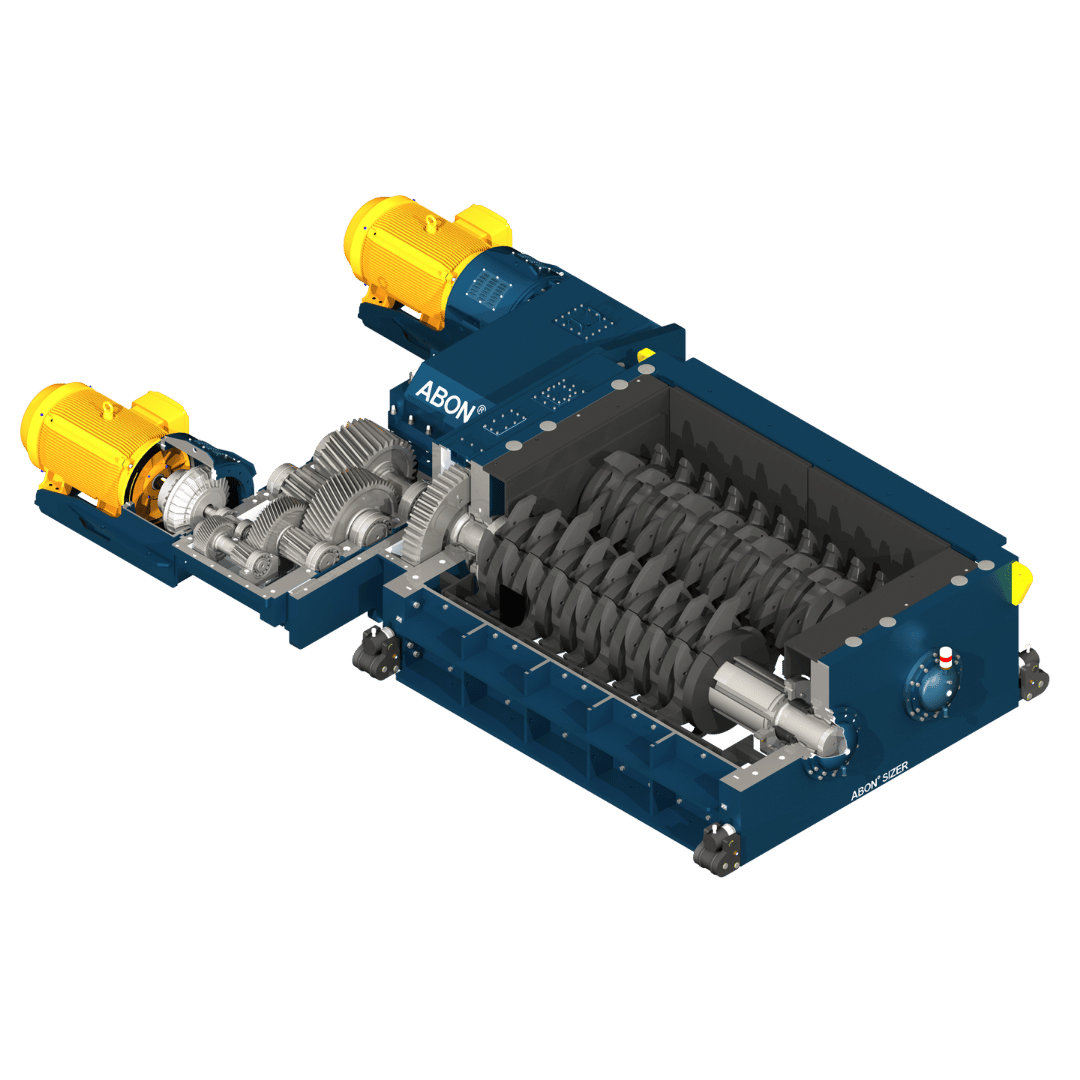

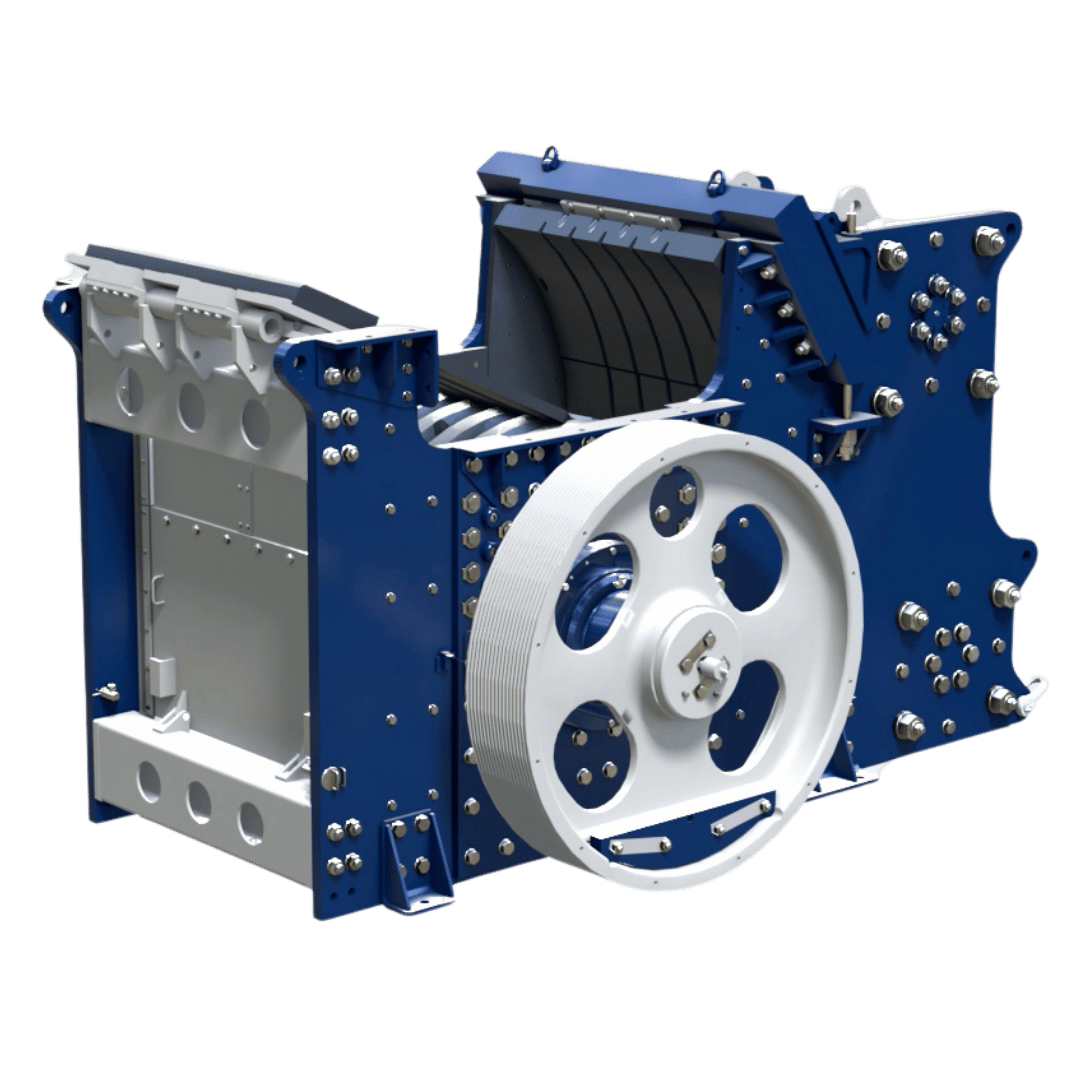

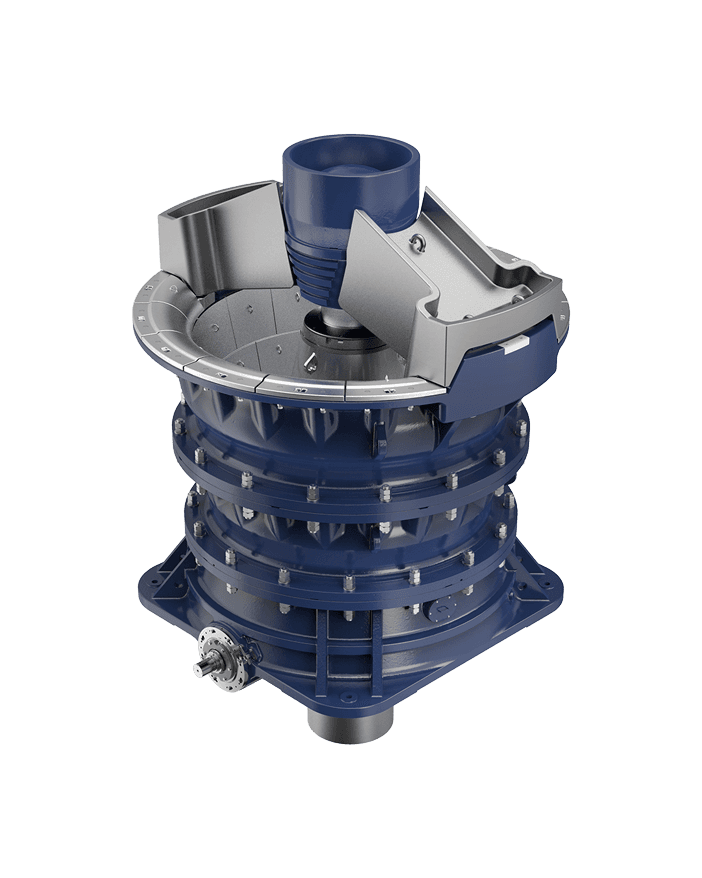

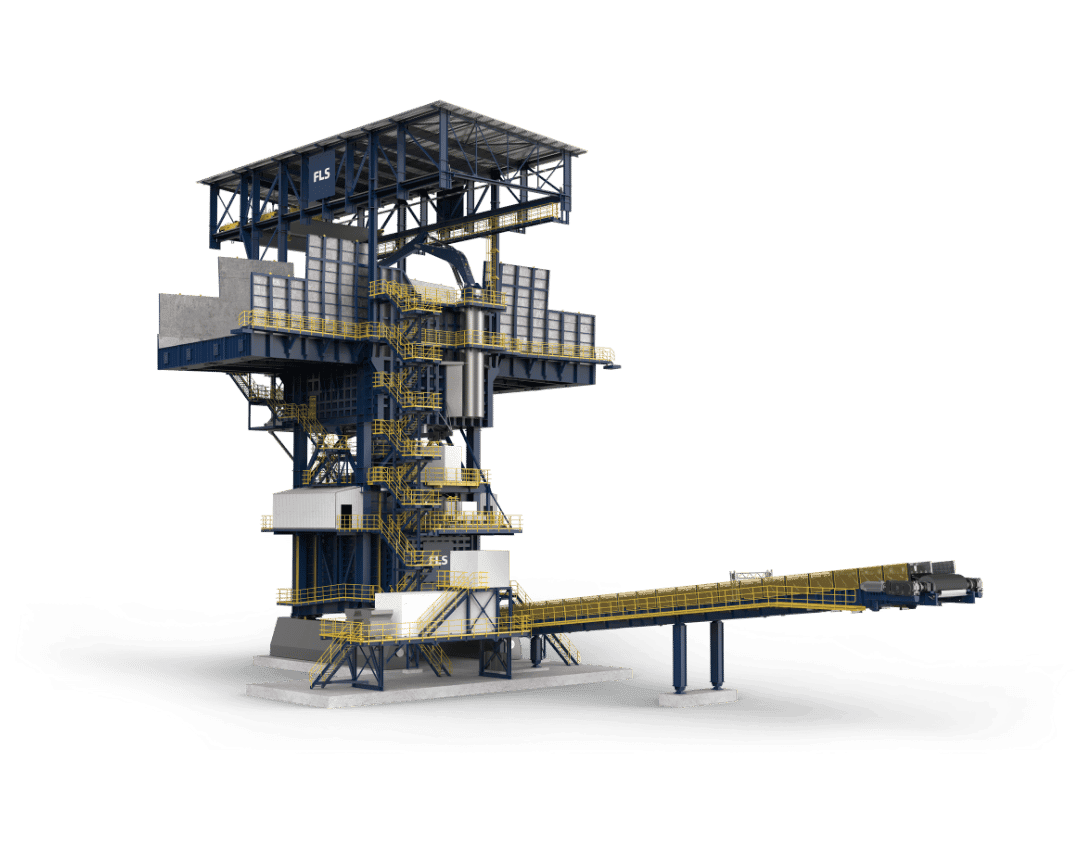

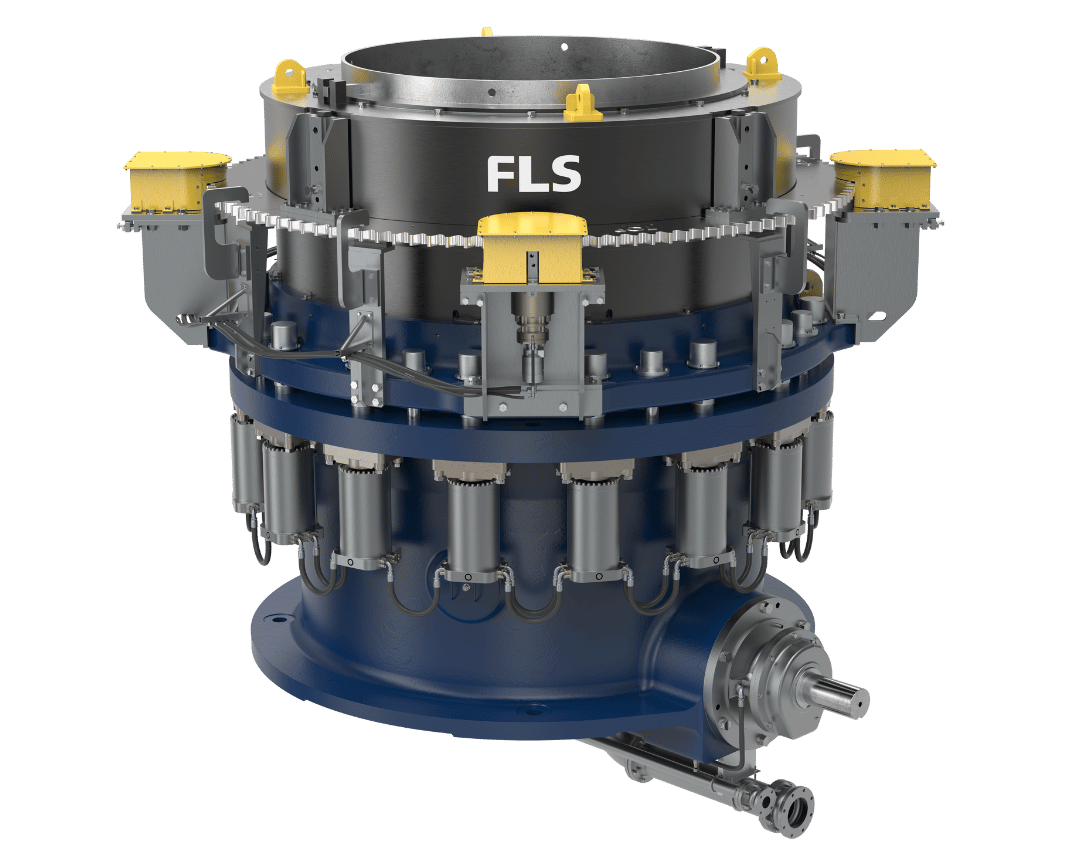

Explore our crushing solutions

Built to last – crushing solutions that last a lifetime

Mining has a long history – and so do we. Our commitment to optimising the comminution process with quality crushers dates back to the Traylor and Fuller-Traylor gyratory crushers of the early 1900s. Since then, our crushers have continuously withstood the harshest demands of the world’s mines and rock quarries – some for more than 100 years. The longevity of these machines means that you don’t have to think about replacing your crusher, but that doesn’t mean you can’t upgrade it. Your crusher’s performance can be improved with the latest wear liners, upgraded components and digital tools and services. You can also rebuild worn parts to bring them back to OEM standards and restore crushing efficiency.