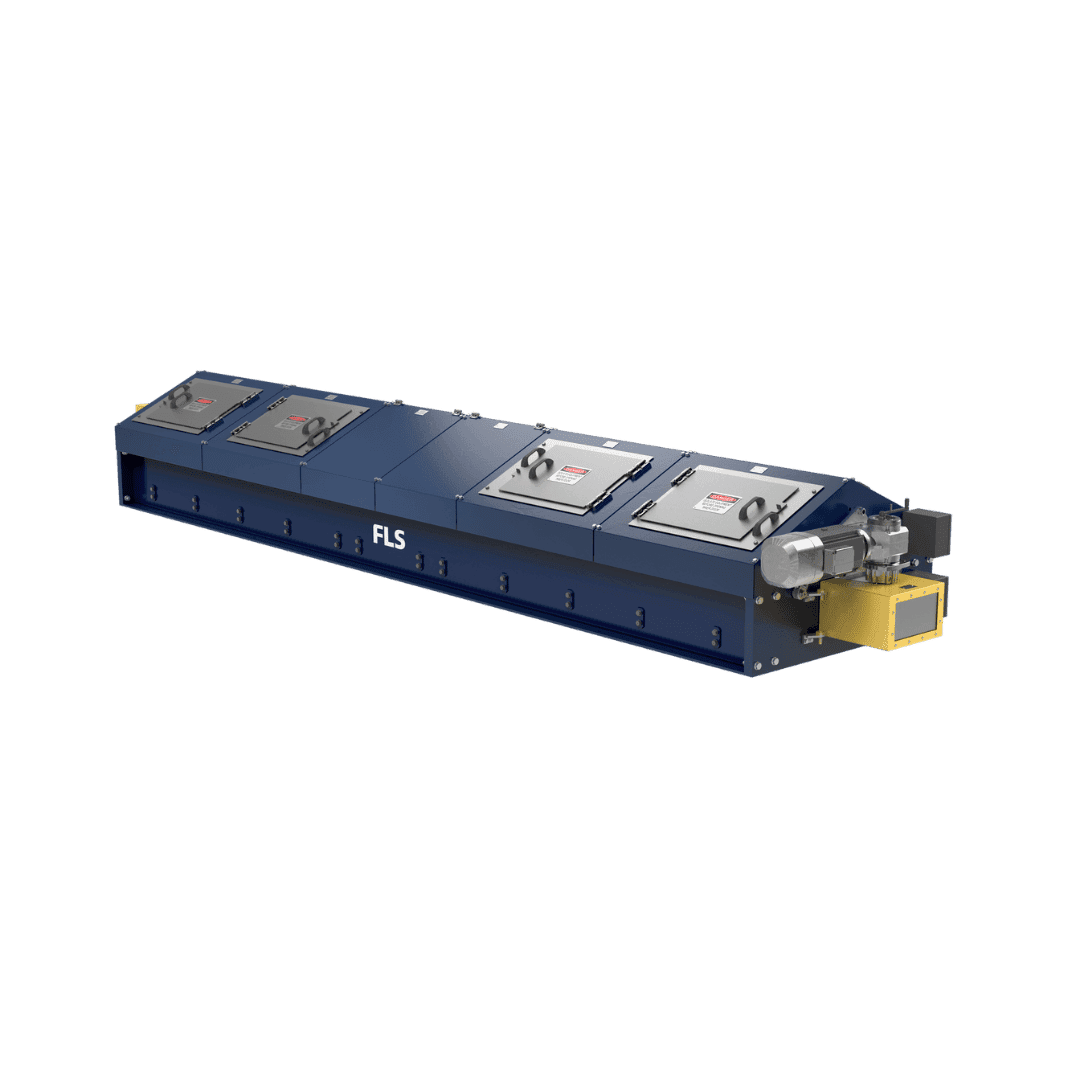

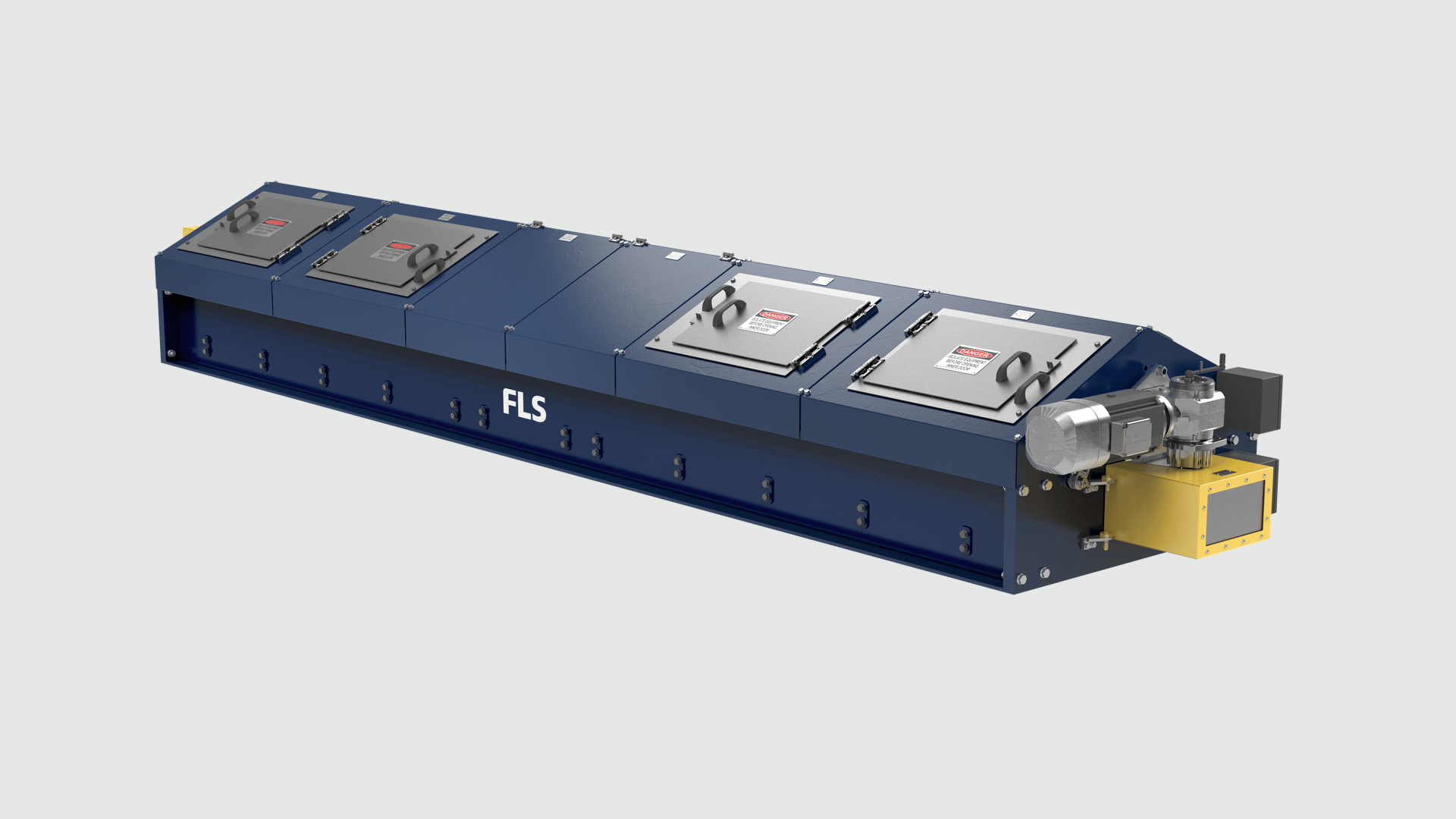

Our dry linear falling stream samplers

Essa® Belt Drive Linear Sampler (BDLS)

The Essa® dry bulk linear falling stream sampler is a full cross-stream sampler specifically designed to sample falling streams from conveyor head chutes. The drive assembly is installed above the sample stream discharge point and a precision-engineered cutter is bolted below the sampler cutter carriage. These samplers can be used for small- to large-tonnage primary applications, as well as for secondary or tertiary sampling.

- Simple, robust low-maintenance belt drive mechanism

- Resilient three-coat paint system finish

- Hinged inspection doors allow viewing during operation

- Hinged safety access screens