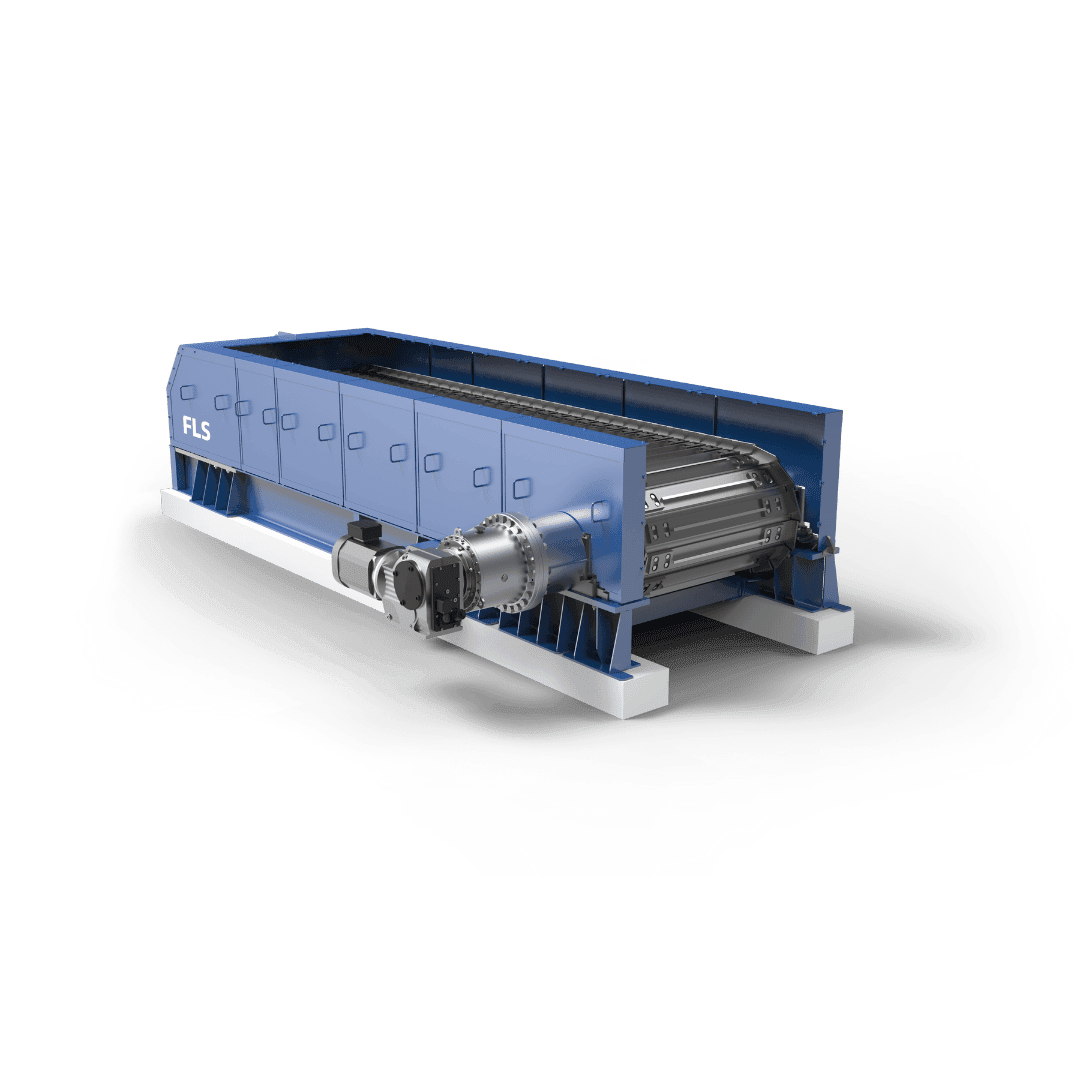

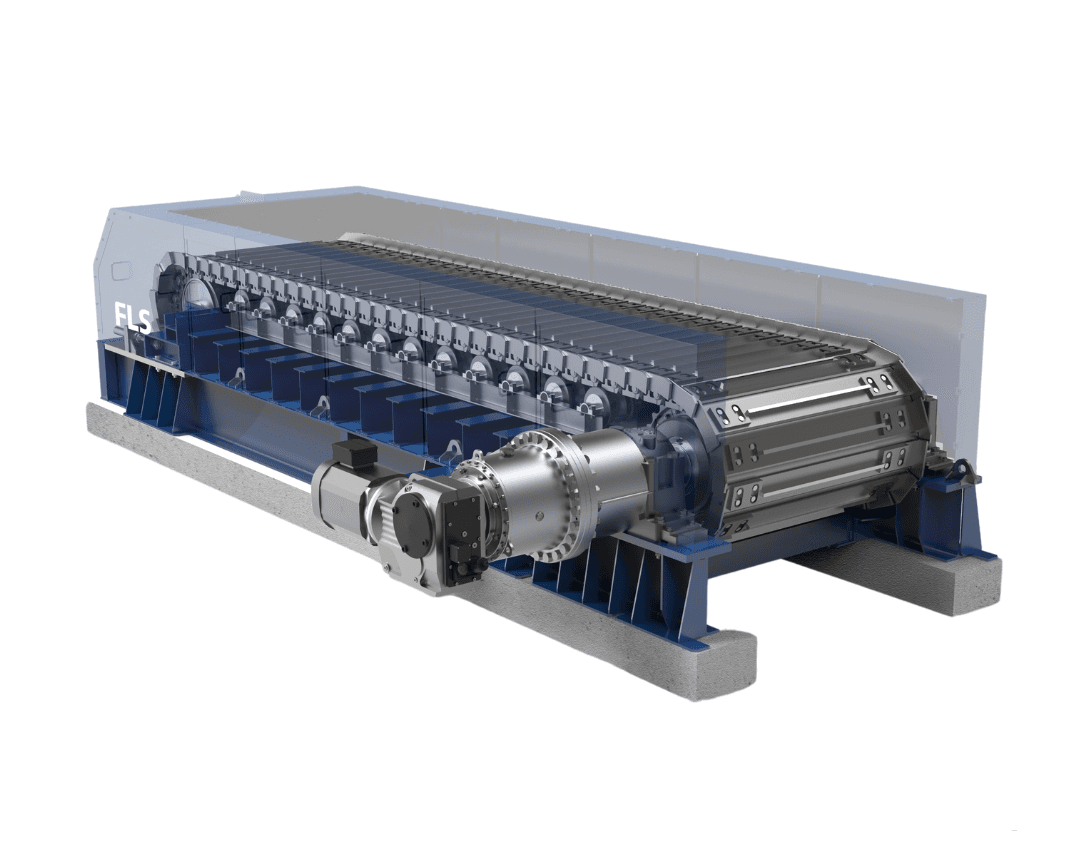

Our apron feeders

We delivered our first apron feeder more than 60 years ago and today make some of the largest apron feeders in the world with throughputs up to 15,000tph, designed to match the capacity of our largest gyratory crushers. These sturdy and reliable pieces of equipment can handle any hard and soft rock ores and are ideally suited to harsh conditions, conveying ore bodies from small to large particle sizes. This, combined with their ability to handle high impact loads, sets our apron feeders apart from most other feeders, making them ideal for the rough-and-tumble operating environments prevelant in the mining industry. Depending on the size of the feeder, it will be delivered to site in pre-assembled sections, or even as a single unit, for quick and easy installation and commissioning.