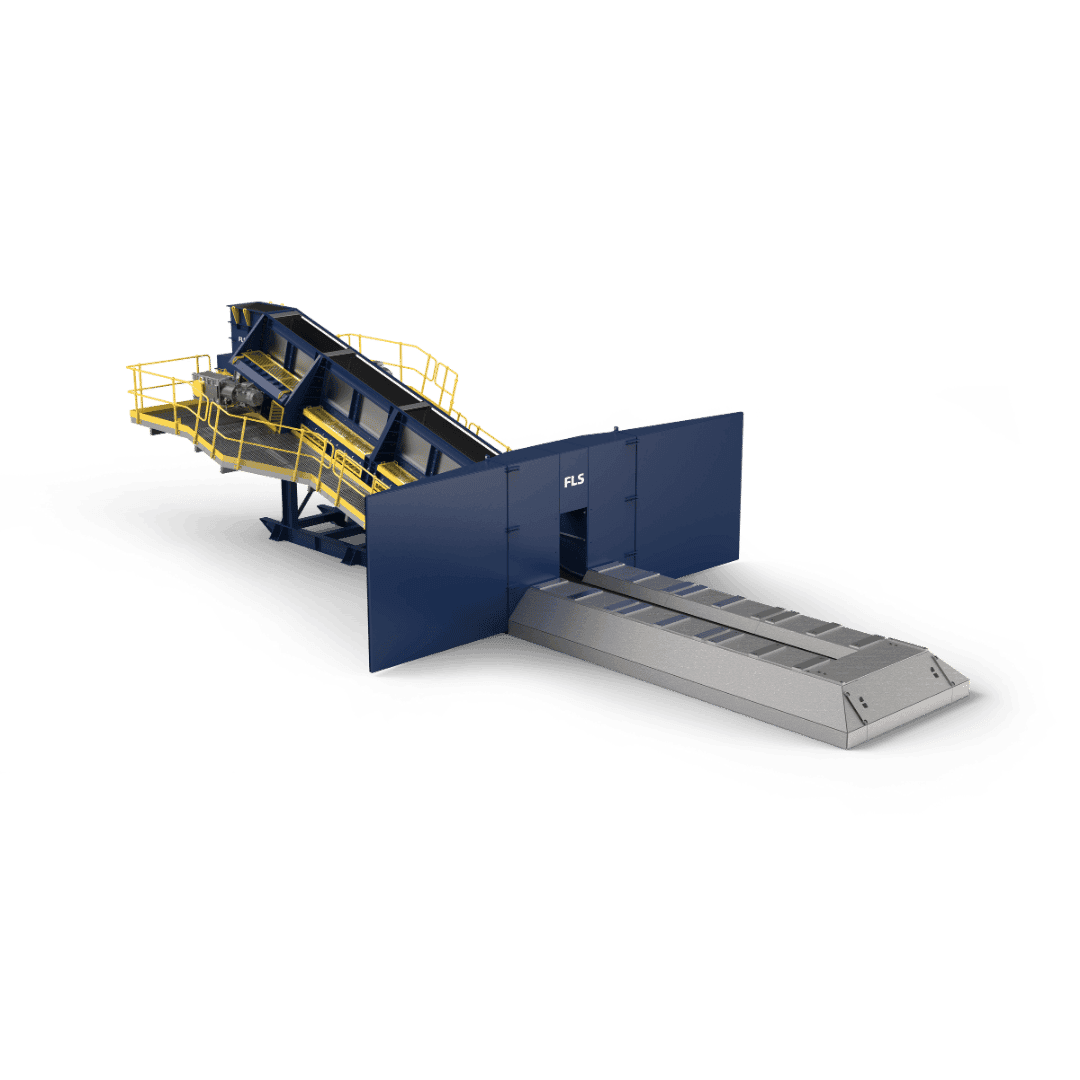

Delivering heavy-duty, reliable performance

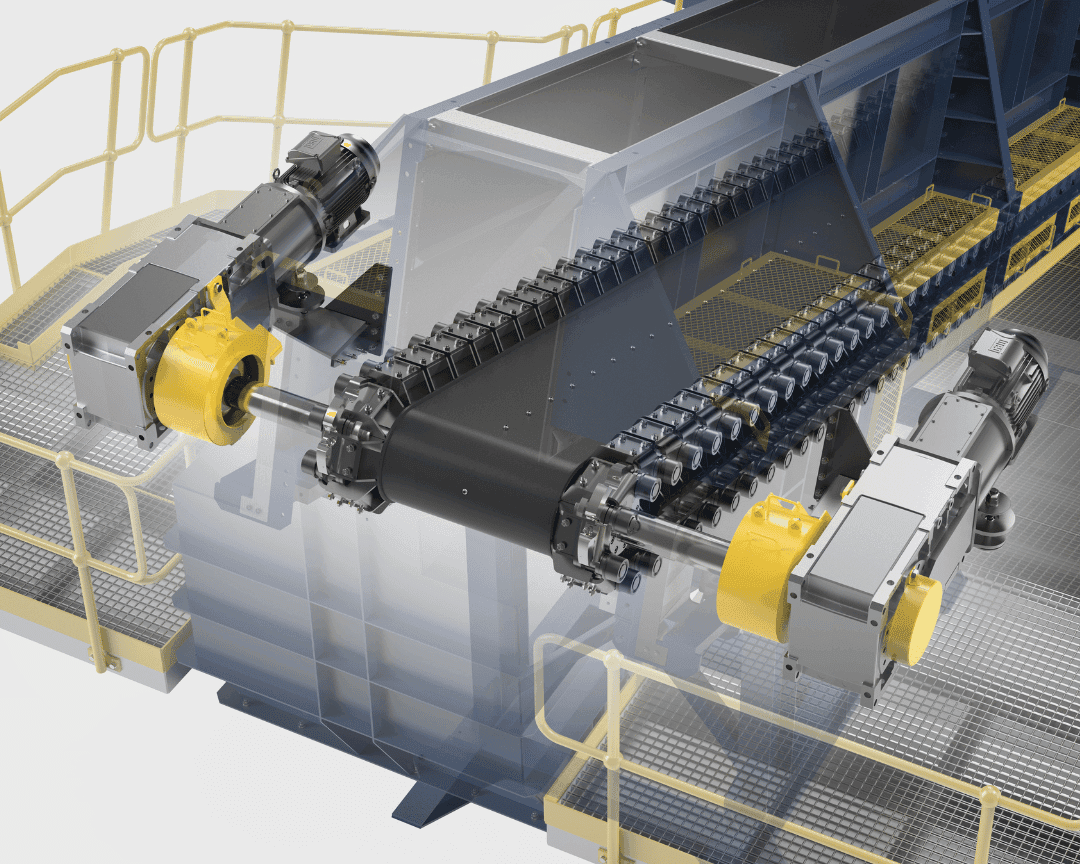

The hybrid apron belt feeder’s heavy-duty construction incorporates conventional conveyor belting, which is bolted to aprons pans. The chain design features double-mounting flanges for effective load distribution while dual carry rollers per chain link ensure low rolling resistance and effective support of the flight bar system. Combined with a reinforced loading deck, bumper flight support bar to absorb loading forces, and robust apron flights, HAB feeders are built to withstand large impact loading forces over long periods of operation.