Our carbon ADR plants

Our full-flowsheet carbon ADR plants are designed to recover gold or silver from a pregnant leach solution and turn it into a final, saleable product. Ranging in size from 6x14 to 8x20 mesh, they can handle solutions loaded with gold and/or silver from 2400 to 10,000 grams per tonne. Our complete systems also include structural steel, piping and valves within the battery limits.

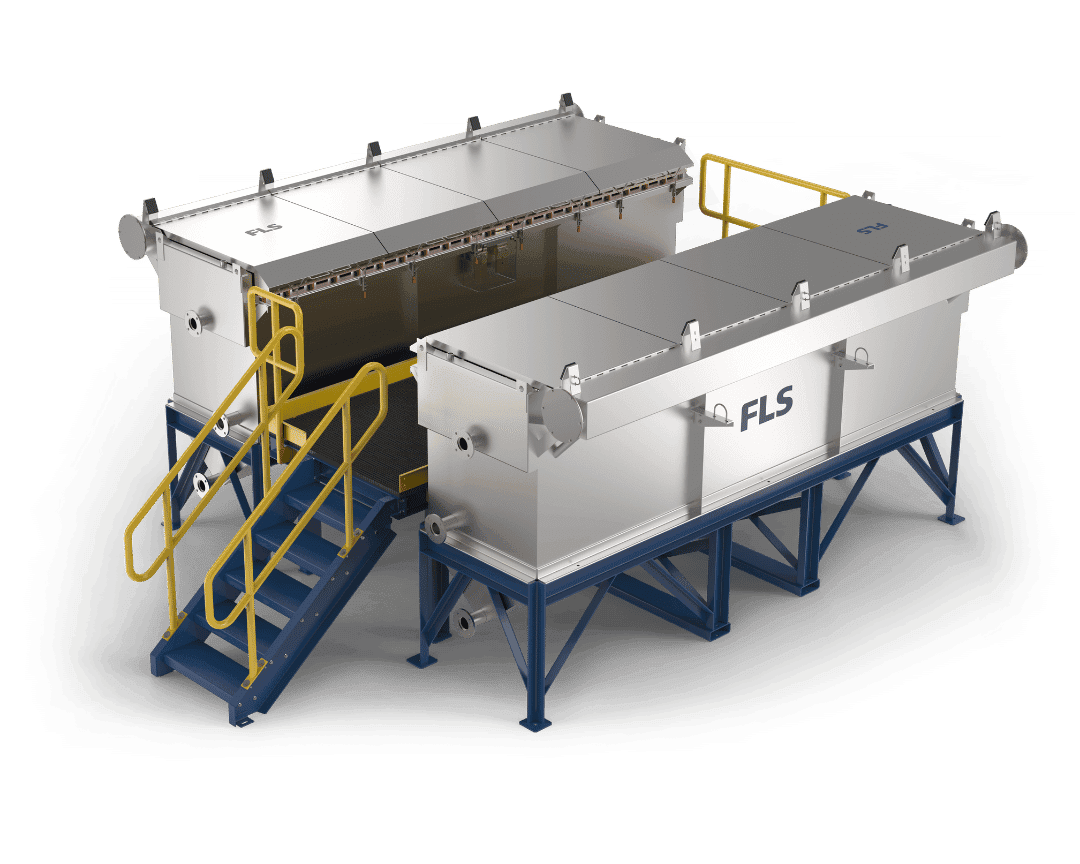

Adsorption

FLS offers a range of leach and adsorption circuits, including carbon in column (CIC), leach-carbon in pulp (CIP) and carbon in leach (CIL), each designed to deliver optimum gold and silver recovery, as simply and inexpensively as possible.

- Proper circuit design.

- Robust and easy to maintain.

- Cost-effective metals extraction.

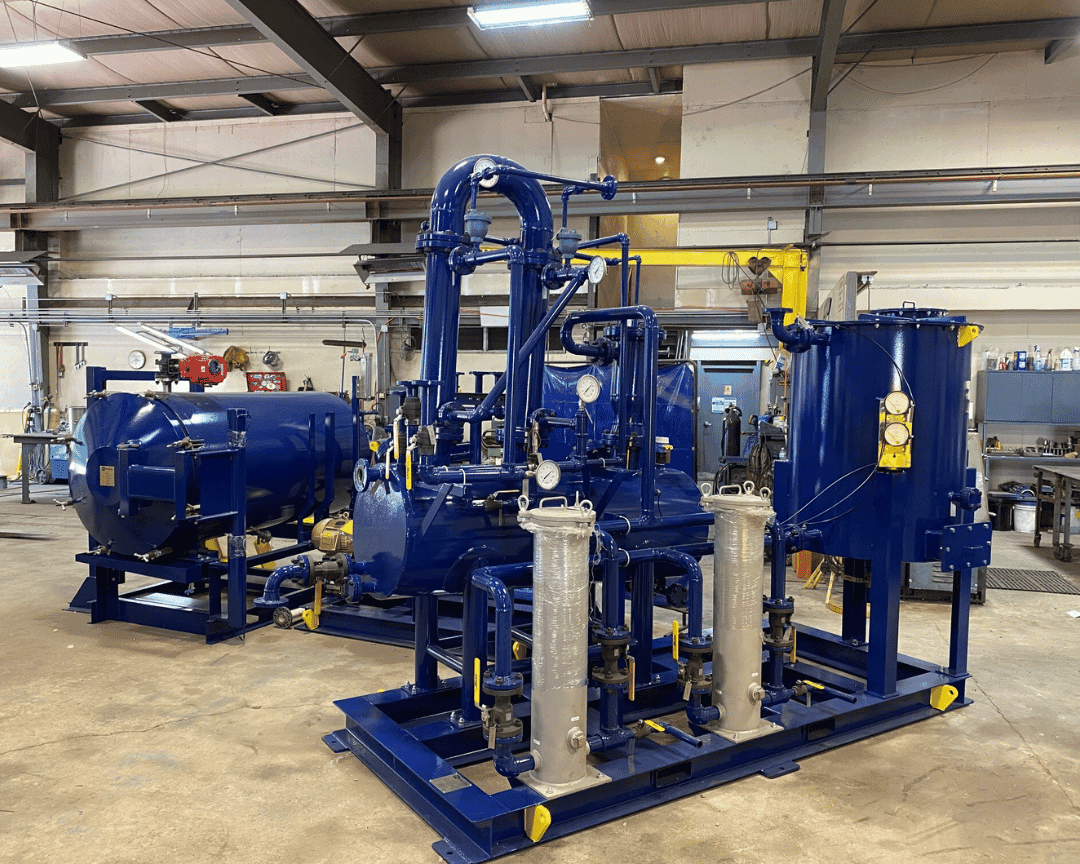

Elution

Our integrated elution/strip systems can process 1 to 72 tonnes of loaded carbon per day, with the highest energy efficiency and significant cost savings. Offering patented Zadra or AARL systems, we select the best solution for your plant.

- Integrated, complete systems.

- Effectively remove metals between 50-100 ppm.

- Optimised energy consumption.