High froth recovery rates

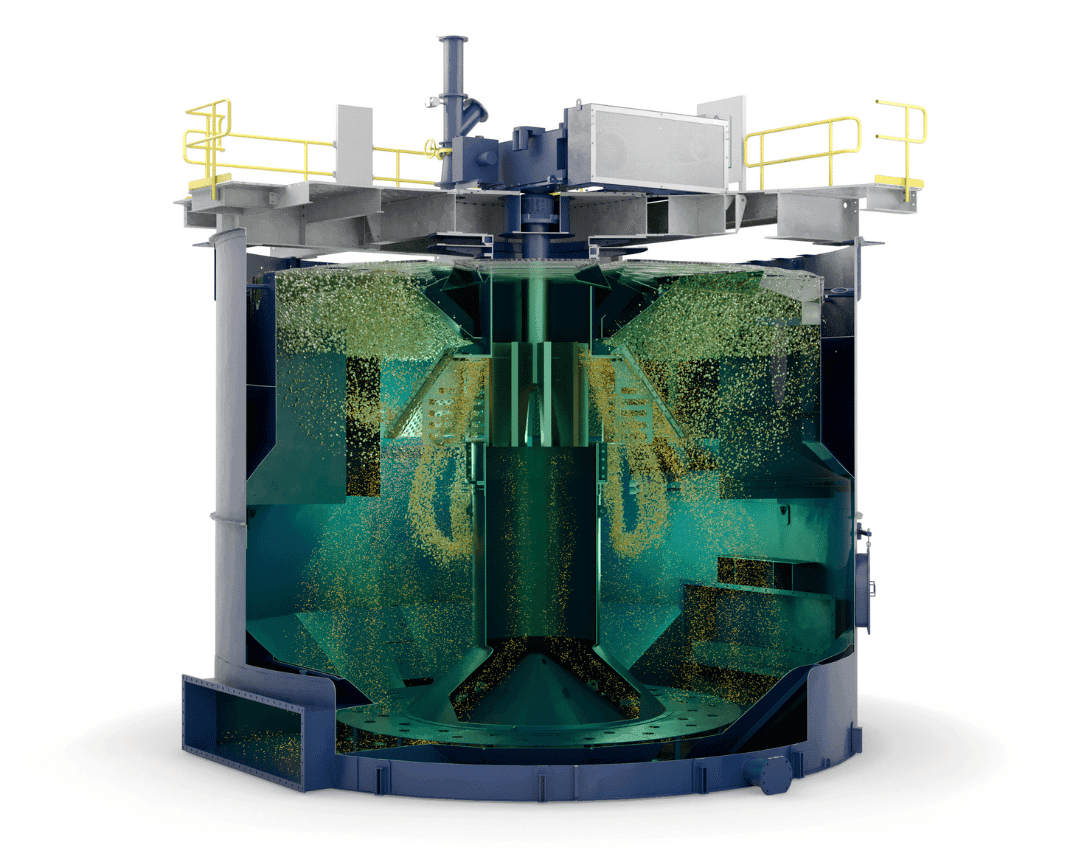

The rotor in WEMCO II flotation cells is located at the top of the cell, resulting in a short travel distance to the launder for attached particles. This ensures highest possible recovery rates, particularly in bulk rougher flotation.