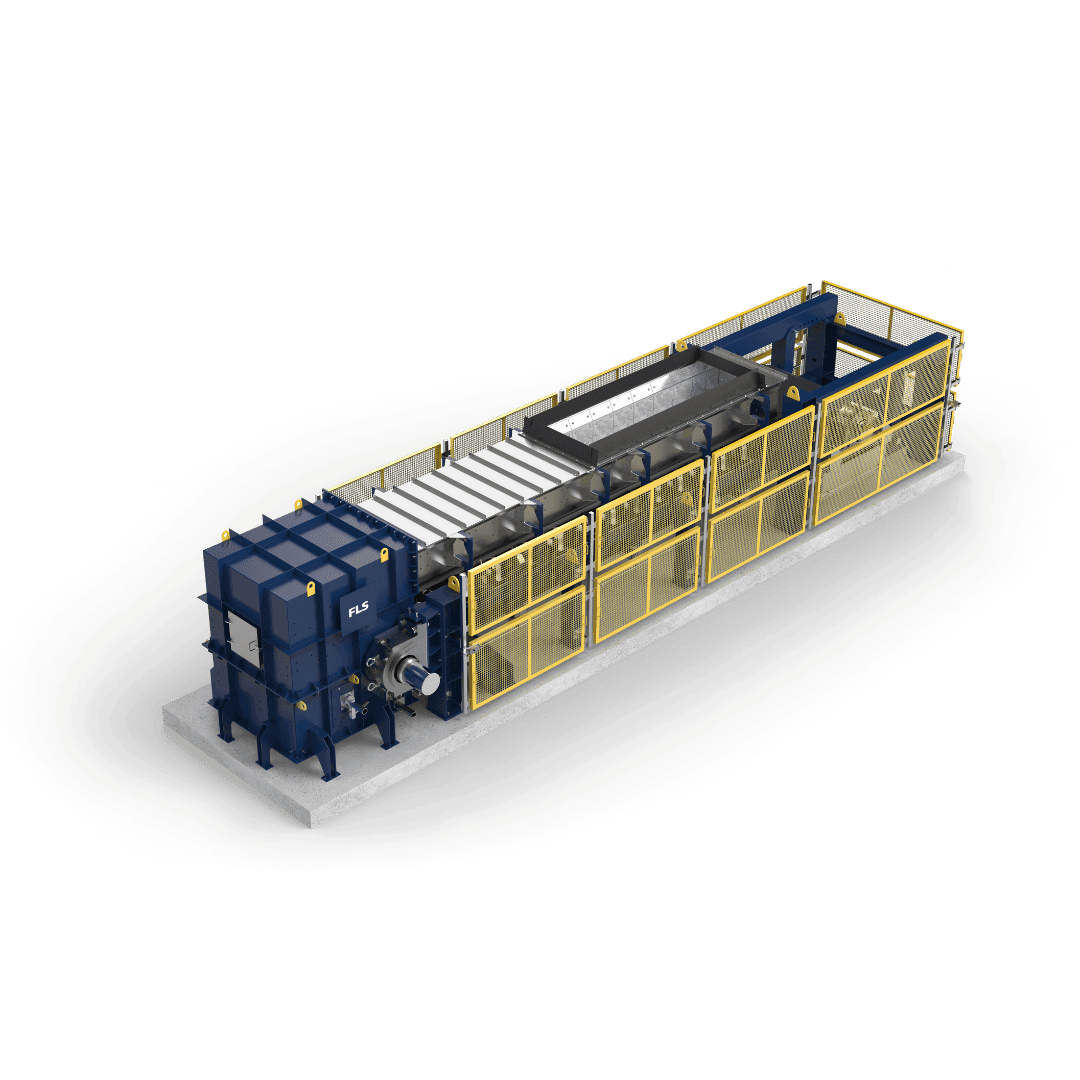

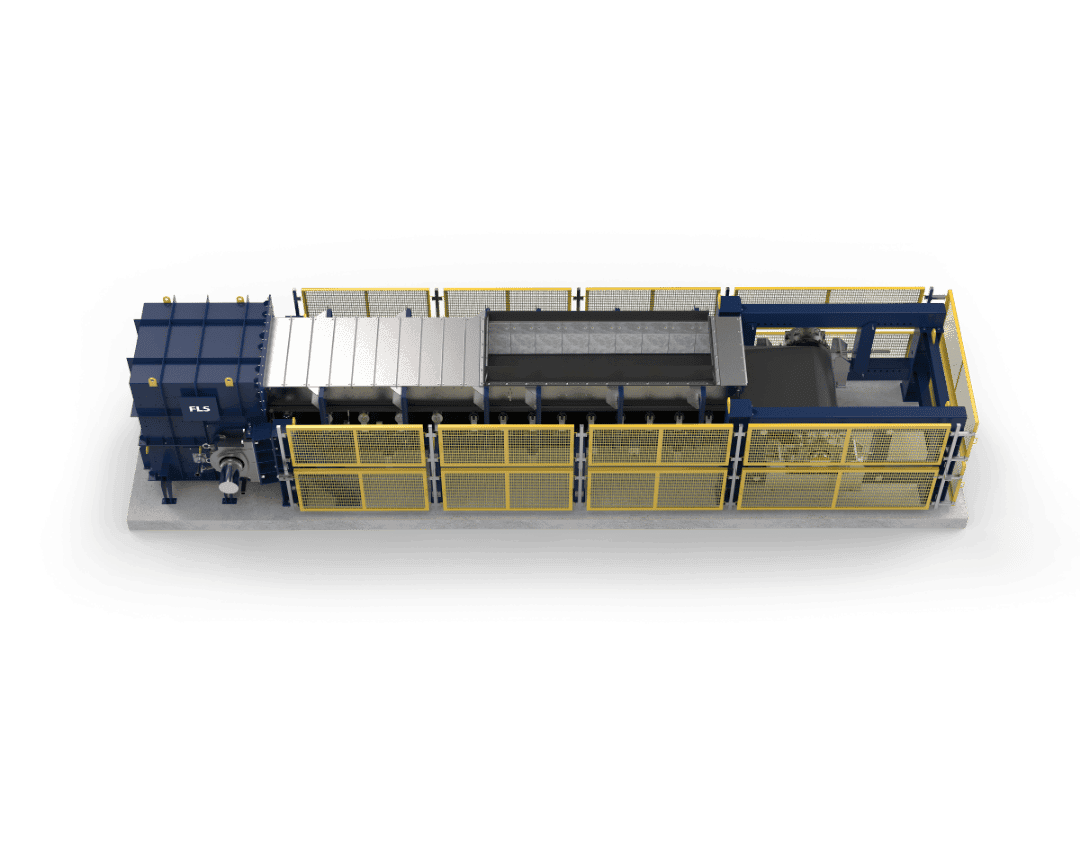

Reliable performance

With dimensions customised to meet specific plant layout requirements and material characteristics, FLS belt feeders are designed for continuous use in even the most challenging mineral processing environments. FLS belt feeders offer reliable, efficient, and economical operation throughout their entire operating life, delivering controlled material transfer in medium- and high-capacity applications.