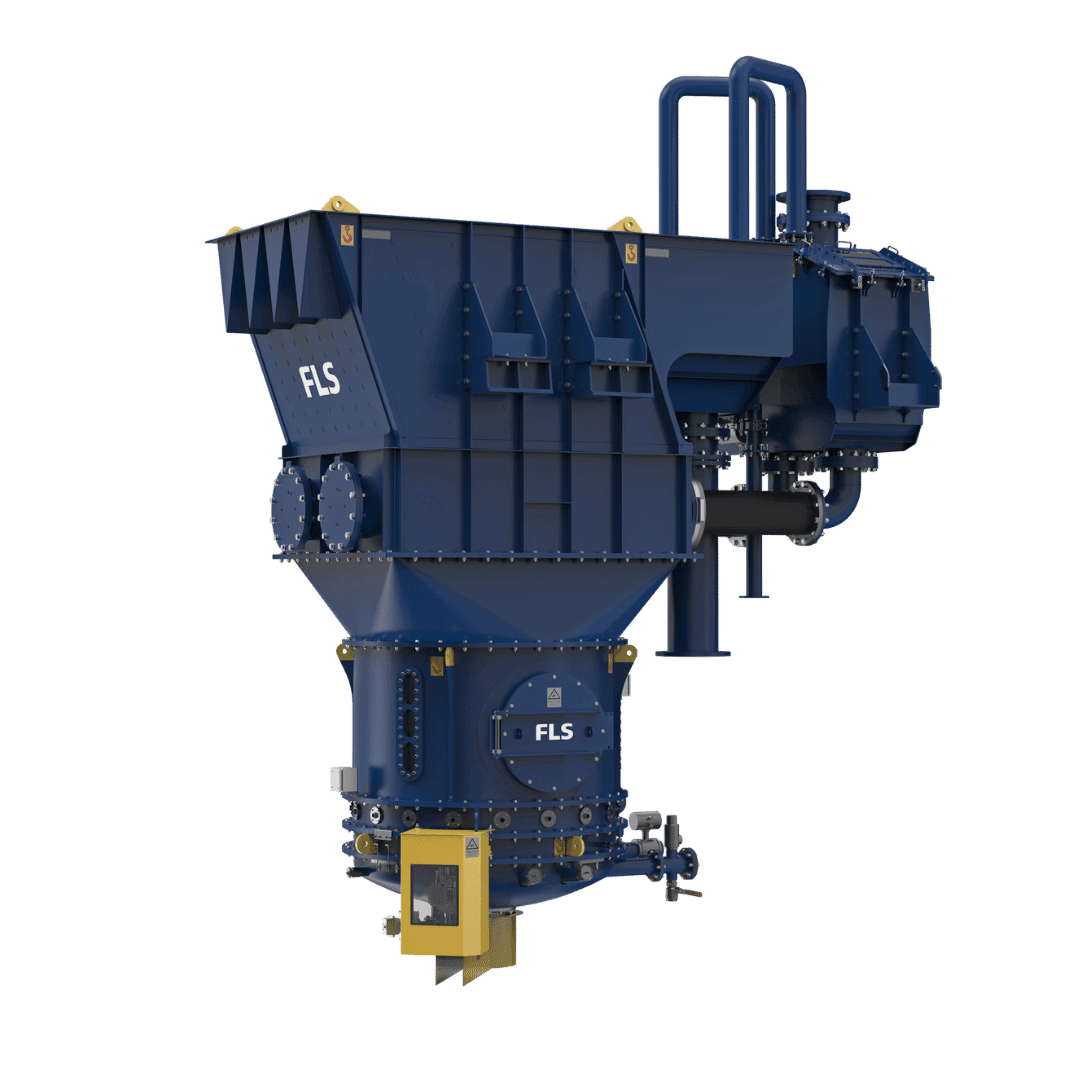

Increase plant throughput

Coarser particle recovery means the mill doesn’t have to work as hard to prepare the flotation feed. This allows mines to increase plant throughput without investment in the grinding circuit. Alternatively, the mine may maintain throughput and reduce grinding energy consumption.