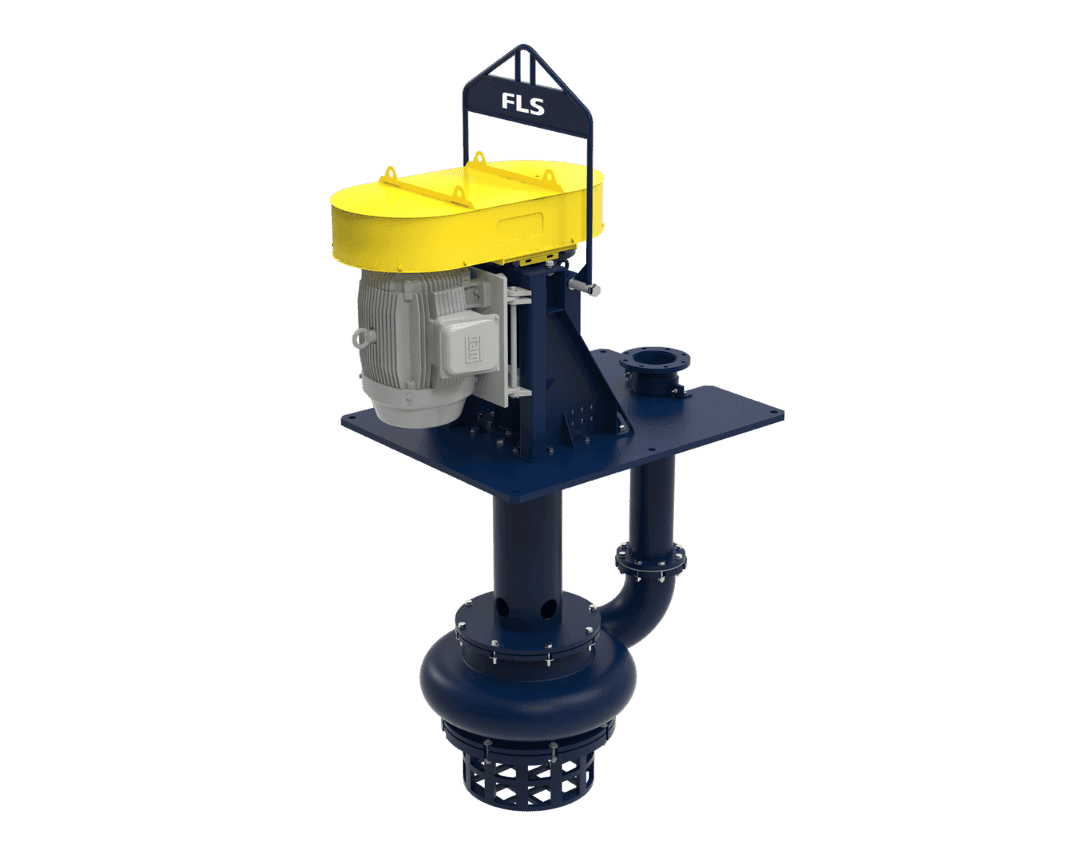

Easily handles slurries entrained with air or gas

The recessed impeller design allows for the clear passage of air-entrained slurries without influencing the duty flow and head. Through constant recirculation, the open vortex impeller design allows for froth advancement without air locking. In fact, the hMAX can handle slurries containing up to 30% entrained air.