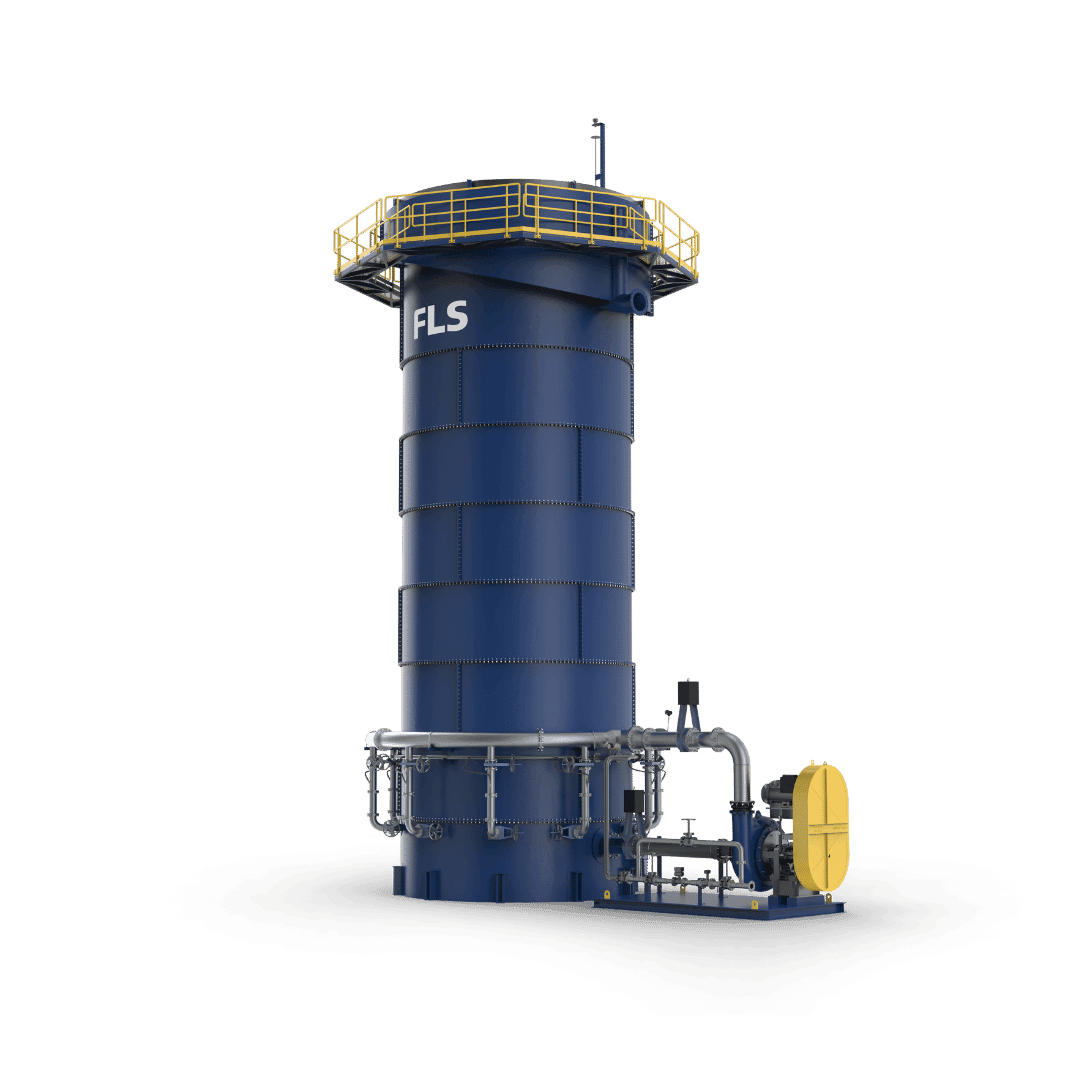

Enhanced fines recovery

The column cell’s large height-to-diameter ratio ensures a large collection zone with ample space for target mineral-bubble attachment. Collision and attachment rates are further enhanced by the venturi-style inline sparging systems, which delivers much higher intensity contacting that traditional jet-nozzle spargers.