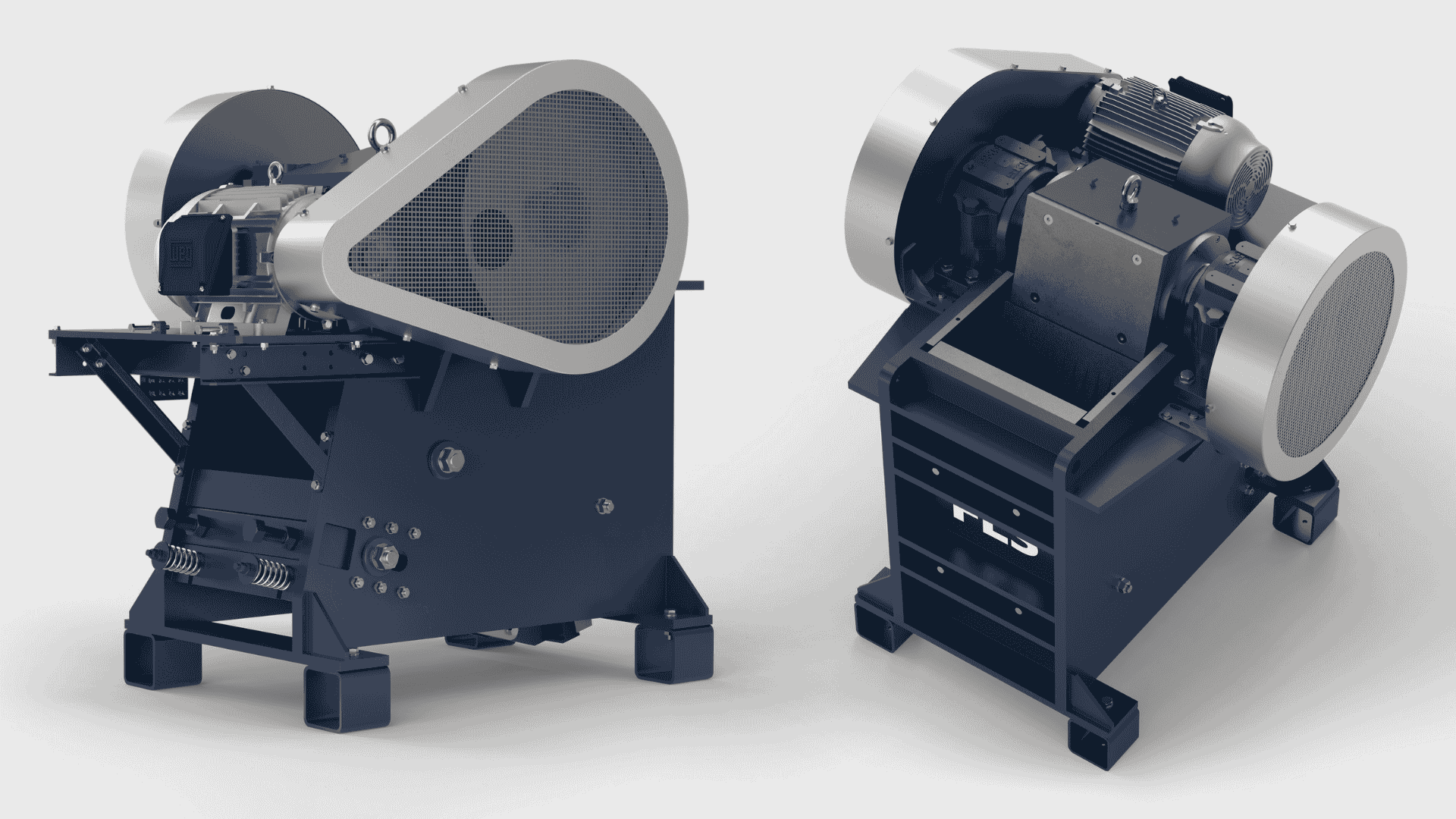

Designed to crush and pre-crush hard and brittle materials, our HSC550 Jaw Crusher is suited for use with a wide variety of materials including alloys, slag, minerals, ores and quartz rock with a feed size up to 50 mm. A proven trouble-free performer, it reliably delivers consistent crushing results across all materials – crushing to a final fineness of < 4 mm and with a selectable gap width of 0 – 20 mm.

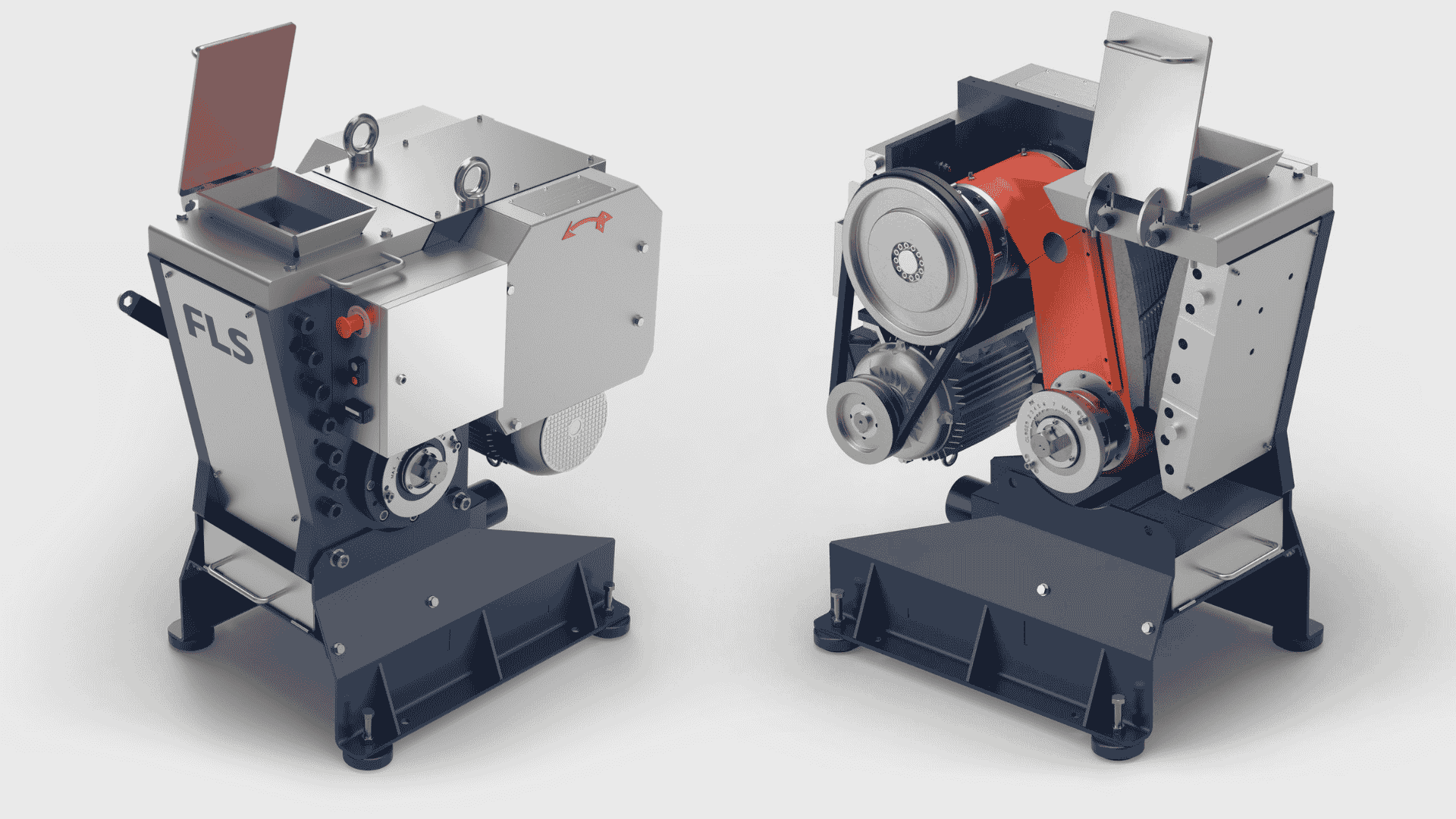

Smart engineering allows the HSC550’s jaw to be easily locked and unlocked using a wide non-slip handle. This facilitates easy inspection and cleaning of the crushing chamber. Additionally, a width display ensures easy adjustment of the gap width, including easy zero-point adjustment for wear compensation.

Safety features like no-rebound feed hopper and brake motor minimizes the risks of personal injury of the operator. The feed funnel cannot be reached into and can be simply hinged open for a fast cleaning of the grinding chamber.

A safety switch and brake motor ensure immediate shut-down if the unit is incorrectly opened or switched on. The fixed crushing arm can be removed easily for cleaning and jaw replacement.

Choose to fit your HSC550 Jaw Crusher with manganese steel, stainless steel, tungsten carbide or special steel grade jaws, on request. You also have the flexibility to collect crushed material in a drawer with a capacity of two litres, or, in the case of large samples, to work without a drawer.