The tailings dilemma

Mine tailings are the waste byproduct left after extracting the economic fraction from ore. Although the exact composition varies according to the ore and processing methodology, tailings generally contain a significant water fraction alongside unwanted gangue material and chemical reagents. Conventional practice is to pump the tailings by pipeline to a surface storage facility and to return water for reuse after the solids settle. However, much water remains in the tailings or is lost and must be replaced, requiring significant annual water draw by mining operations.

Although offering low CAPEX and OPEX, conventional tailings management poses the following problems:

- Highly inefficient water recovery

- Containment required (higher risk of TSF failure)

- High potential for run-off and seepage

- Challenging rehabilitation (high rehabilitation costs)

Several factors exacerbate this tailings water dilemma. Many mining regions are in water-scarce areas. Climate change is anticipated to increase the frequency of extreme water events, such as droughts, which reduce water supply and risk water conflict with local communities, and floods, which risk inundating tailings storage facilities, causing them to fail. At the same time, declining ore grades will increase the amount of ROM material processed, generating more tailings and consuming even more water.

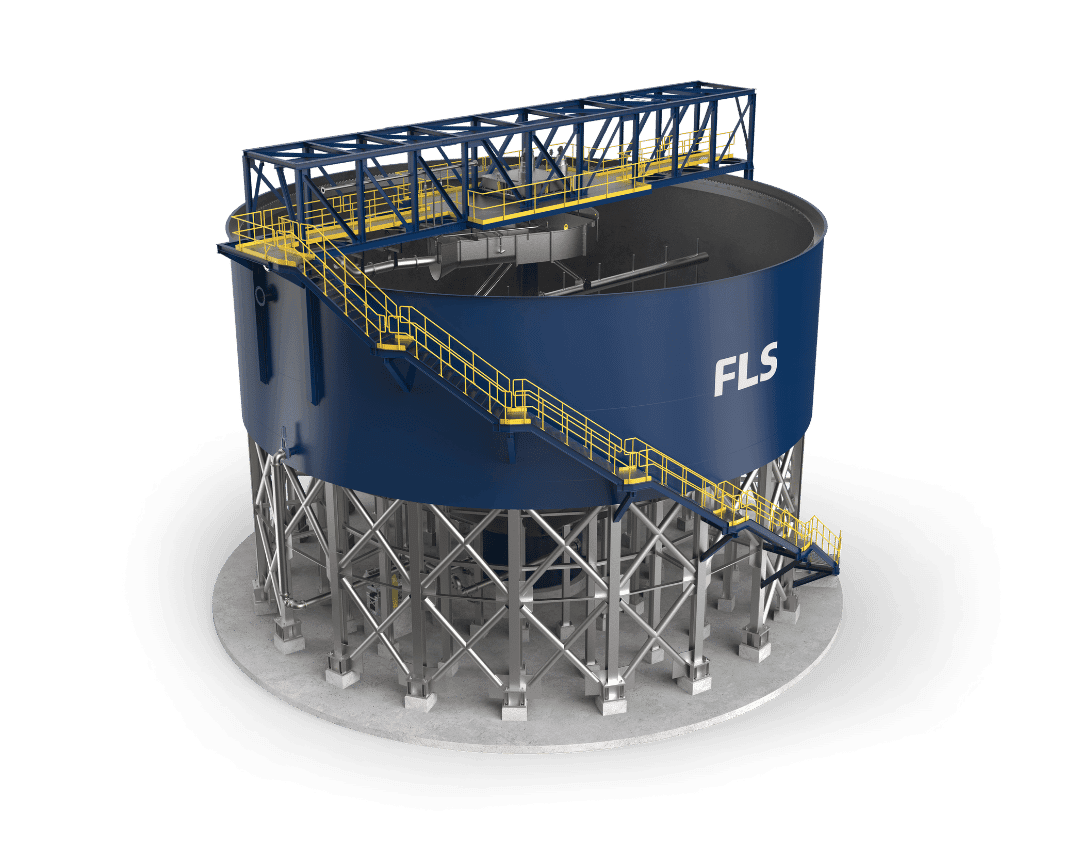

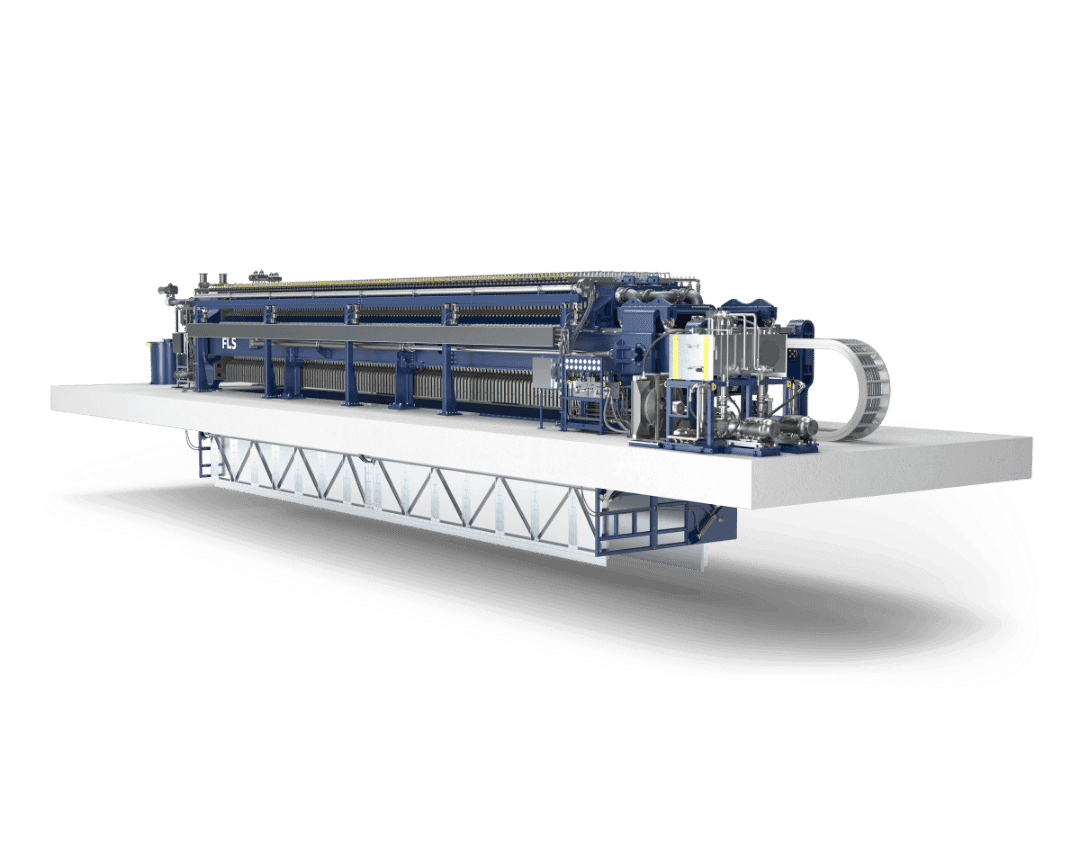

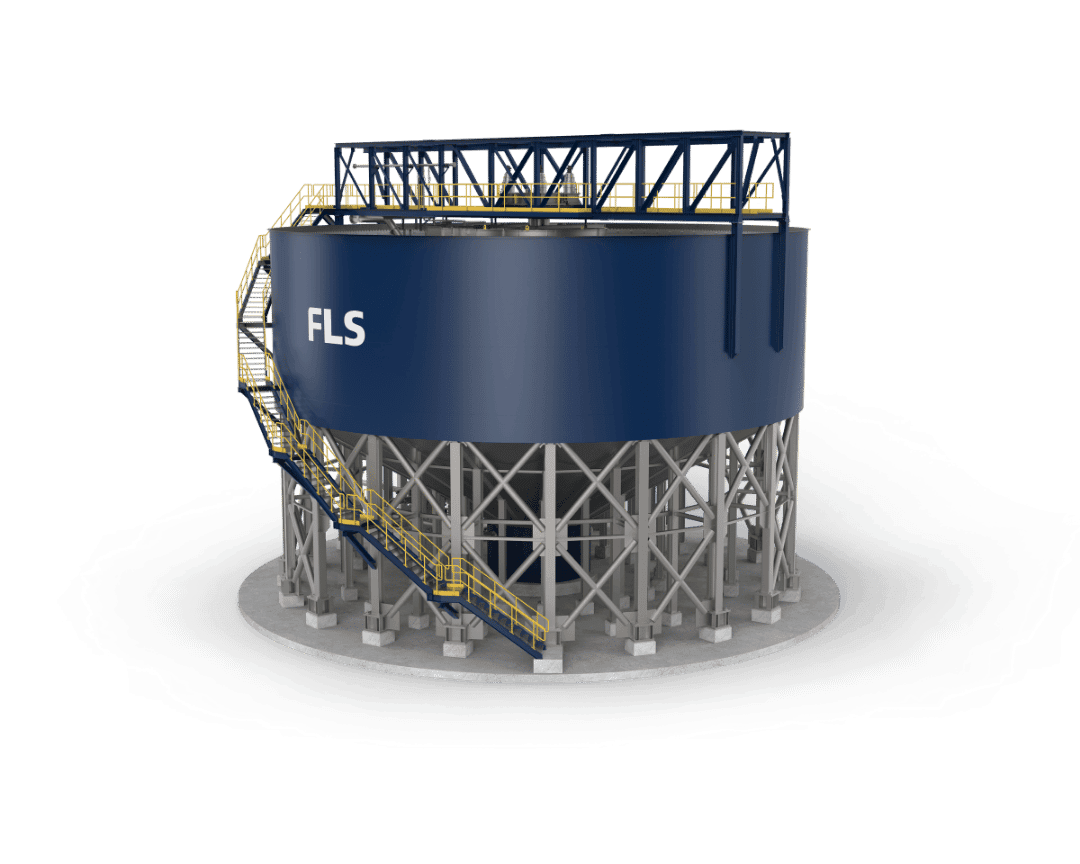

With estimated annual tailings production well exceeding 10 billion tonnes, a new paradigm is urgently needed to reduce tailings volume and maximise tailings water recovery. Technological innovation will be important in developing this new paradigm, with FLS offering several solutions to enhance tailings water recovery and treatment.

As with most sustainability innovations in mining, there is no one-size-fits-all solution for tailings water recovery and recycling. The most appropriate tailings management solutions will depend on several factors. For example, climatic conditions play a part in determining the economics and practicality of tailings dewatering. Water costs tend to be low in wet climates, making tailings dewatering economically unattractive. In contrast, tailings dewatering will be more economically viable in dryer climates due to the higher water cost, which offsets dewatering and water treatment costs.

Mineralogy and topography also impact any tailings management plan. The type and quantity of clays in a deposit can significantly impact tailings dewatering: high clay content results in low dewatering rates and the need for higher-capacity, more expensive equipment. Flat ground requires expensive dams to enclose any wet tailings storage facility, while valleys only need a dam at the end to contain tailings (but capacity is limited). There is also the simple need for space. Remove the water, and you extend the operating life of any storage facility.