Key equipment features

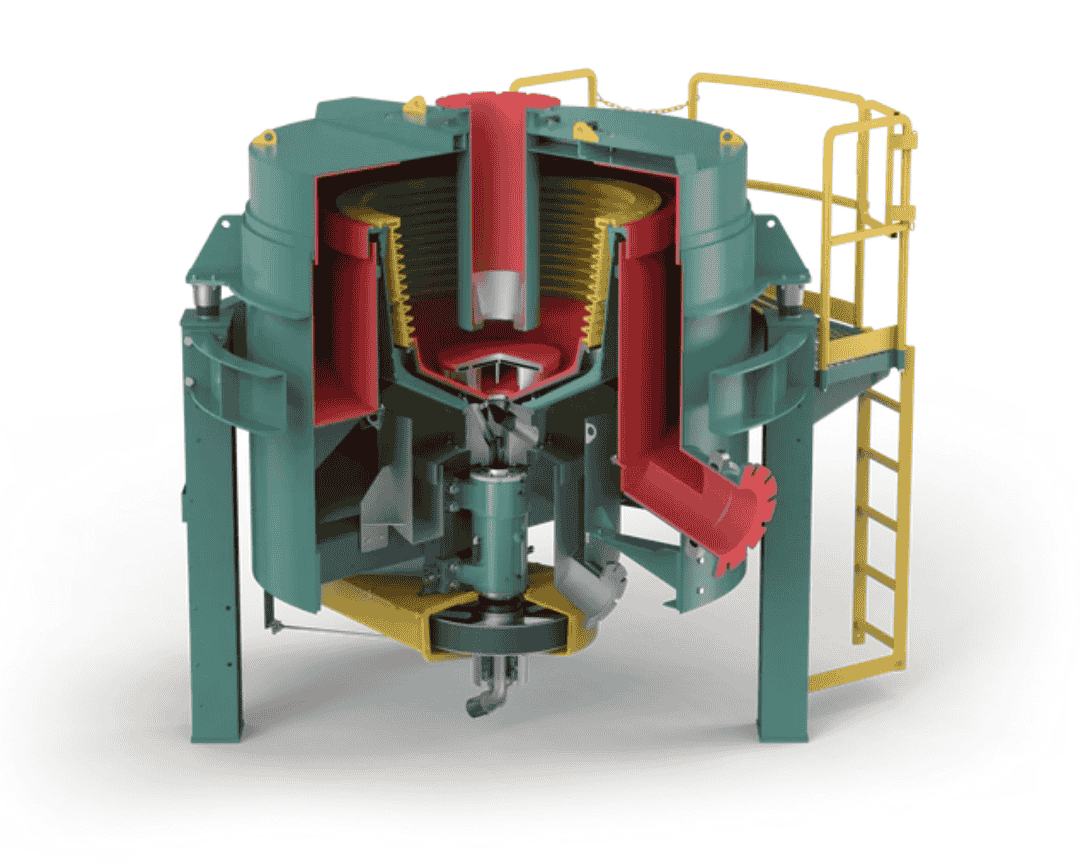

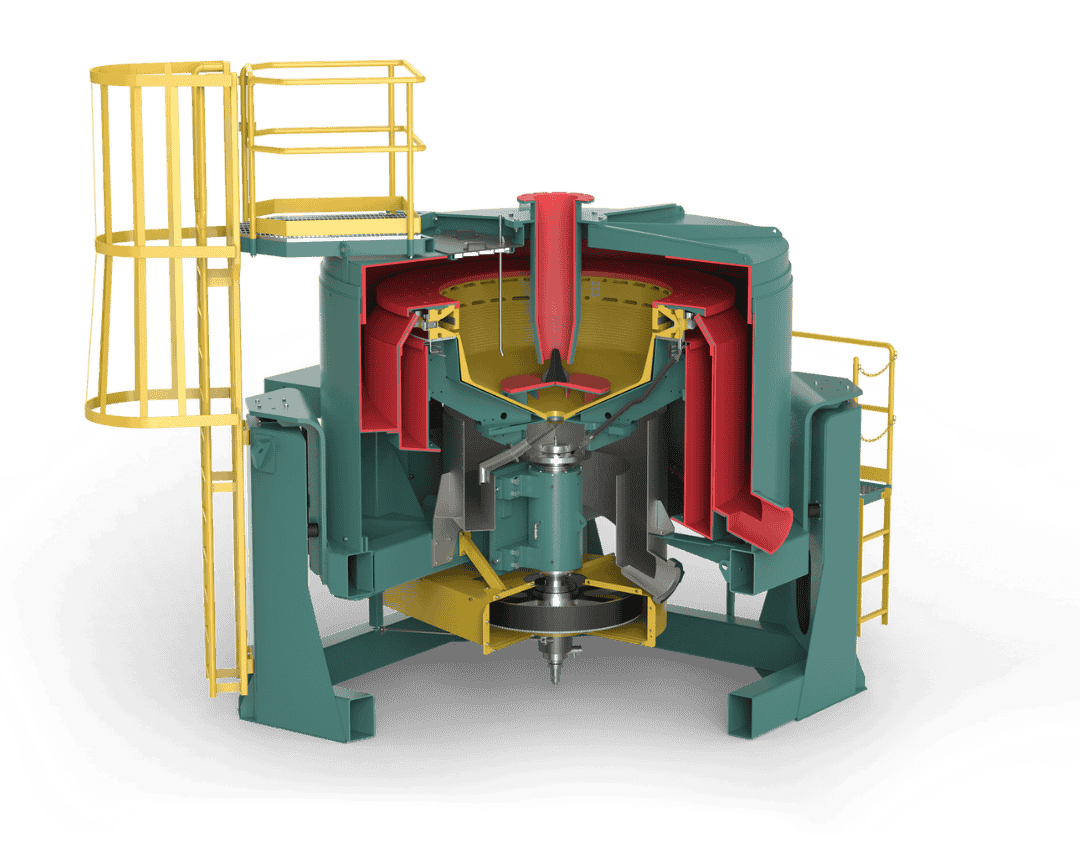

Tangential water distribution

The GX cone features tangential introduction of fluidized water into the concentrating rings, avoiding ratholing and dead spots. It also allows thorough flushing of the unit without the need for expensive and unnecessary variable frequency drives.

Designed to eliminate vibration

We designed the Knelson gravity concentrator with a low centre of gravity and to be hung rather than supported from below, eliminating overall vibration. In contrast, similar products on the market can face problems with vibration if the feed is not properly diluted.

Low number of parts

Knelson gravity concentrators are designed to reduce component parts, simplify construction, and reduce manufacturing time. These measures cut maintenance costs without impacting recovery rates or capacity.