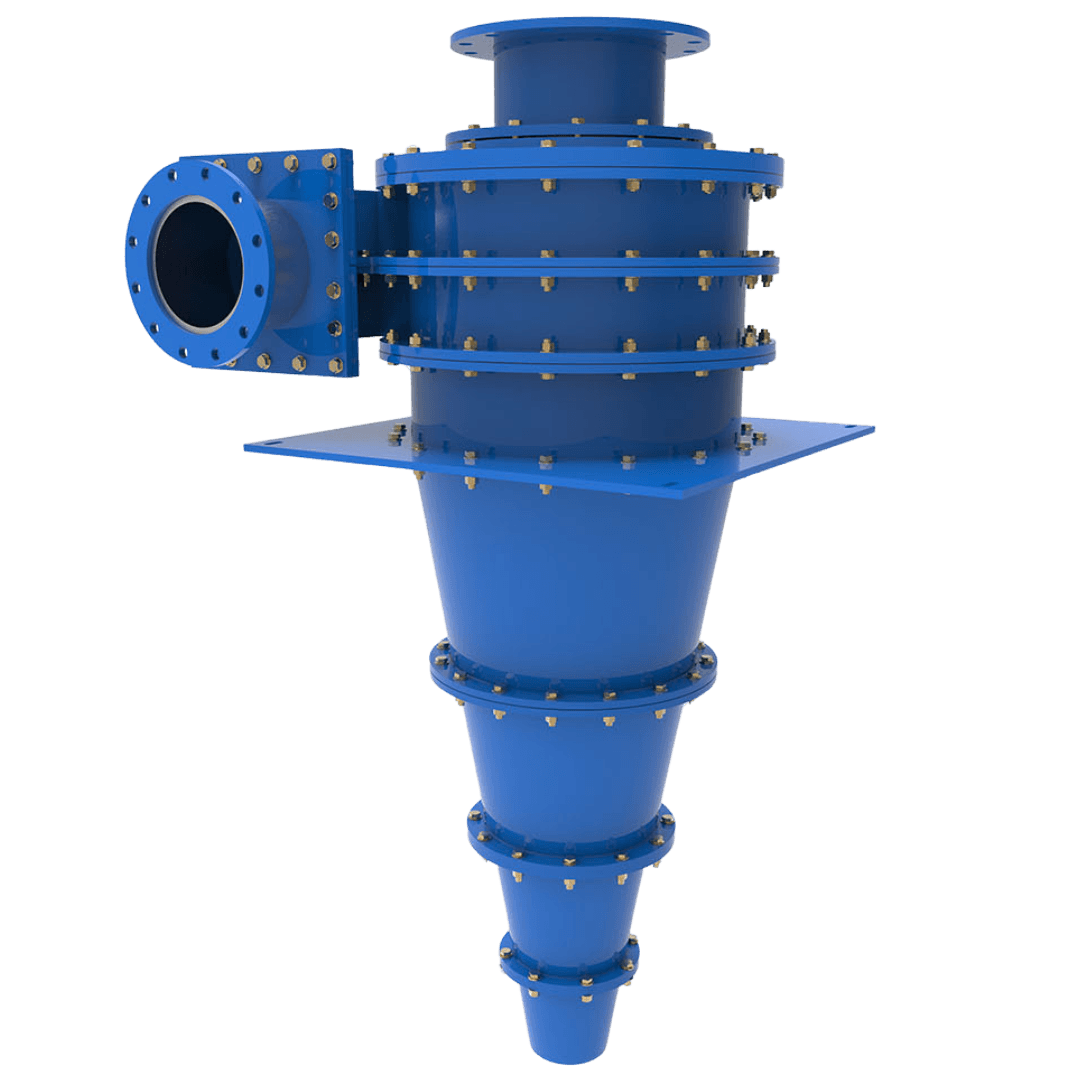

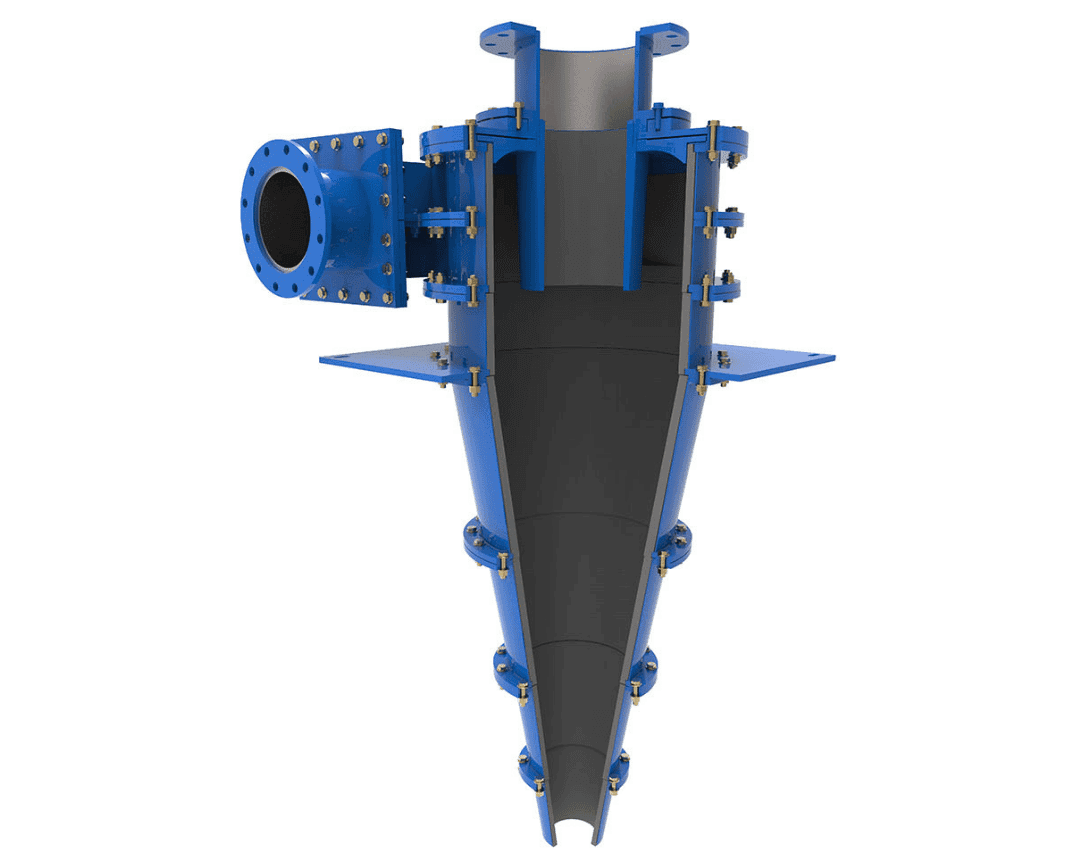

High-efficiency separation

FLS heavy-media cyclones boast exceptional efficiency thanks to various design features incorporated from the KREBS D26B cyclone, the industry’s standard high-capacity cyclone as well as for larger sizes. The use of centrifugal force enhances separation of fine particles, which cannot be efficiently recovered using static heavy-media vessels. Our heavy-media cyclones are relatively inexpensive and typically require little operator attention or maintenance.