Increase recovery. Increase efficiency. Increase availability. Increase throughput. Increase safety.

Crusher upgrade

Increased crushing capacity and feed size, enabling greater productivity through the process.

Learn more

Screening rebuilds

Reduced downtime as part of a predictive maintenance strategy and increased overall plant utilisation.

Learn more

Grinding upgrades

Increased throughput up to 20%, up to 15% energy savings and up to 30% longer roller life.

Learn more

Flotation upgrades

Reduced energy use by up to 40% and increased material recovery.

Learn more

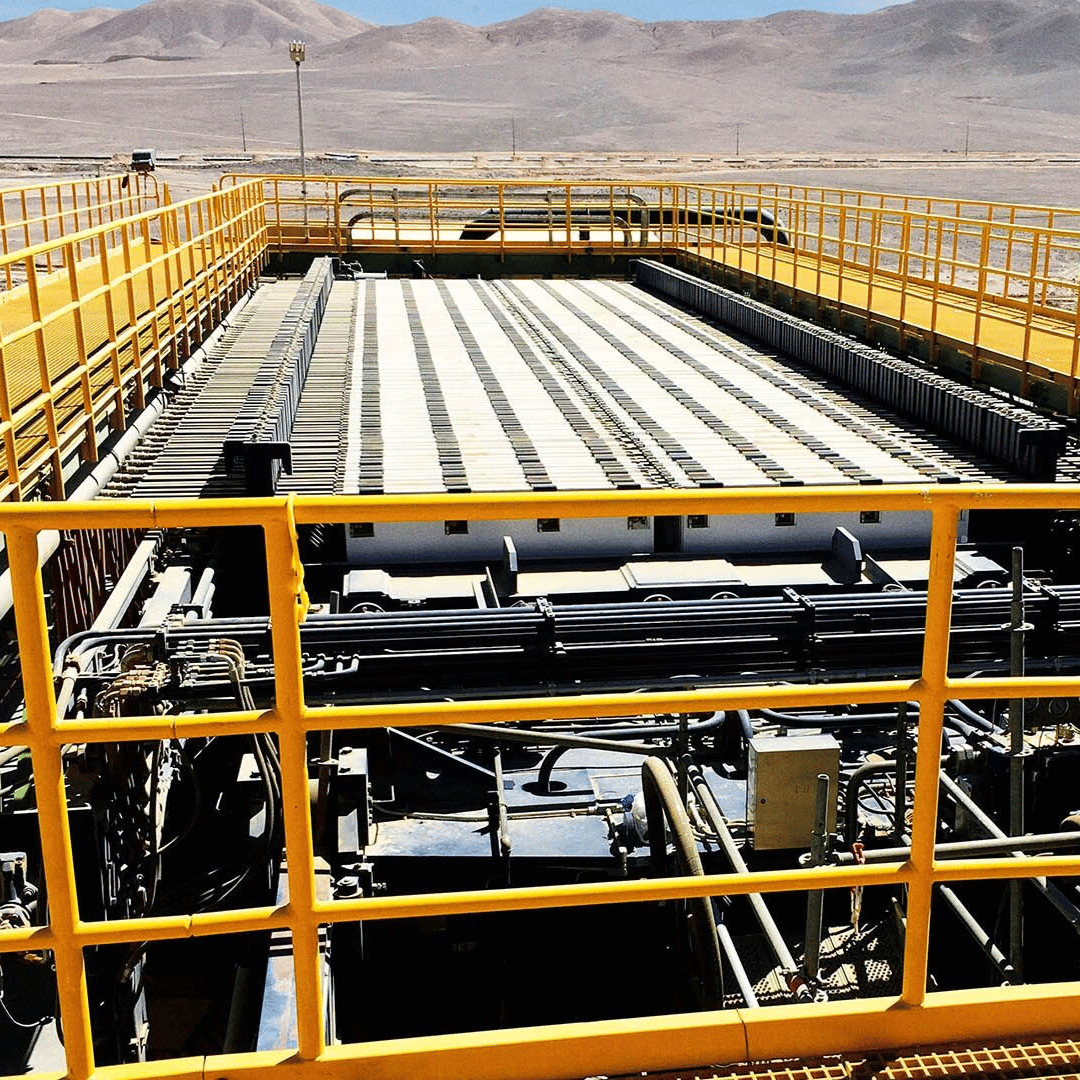

Thickener and clarifier upgrades

Improved water recovery by up to 46%, reduced flocculant consumption and increased availability.

Learn more

Filtration upgrades

Increased filter area by up to 15%, plus greater throughput and enhanced filtration efficiency.

Learn more

Rebuilds

Improve equipment availability by replacing older less reliable components with new.

We provide upgrades, rebuilds, and exchange service to the entire mining flowsheet

Tailored solutions to achieve your production goals

Gyratory crushers, jaw crushers, cone crushers and eccentric roll crushers (ERC®) crushers are all served by our upgrades & rebuilds service team. We take a highly bespoke approach to each project to determine the best solution to meet your production goals.

Enhance performance

Upgrades and rebuilds are available for SAG mill, ball mill, rod mill, tower mill and high pressure grinding rolls (HPGR). Upgrade to HPGR Pro to experience up to 20% increase in throughput with significantly lower energy consumption. HPGR rolls are also served by our exchange programme.

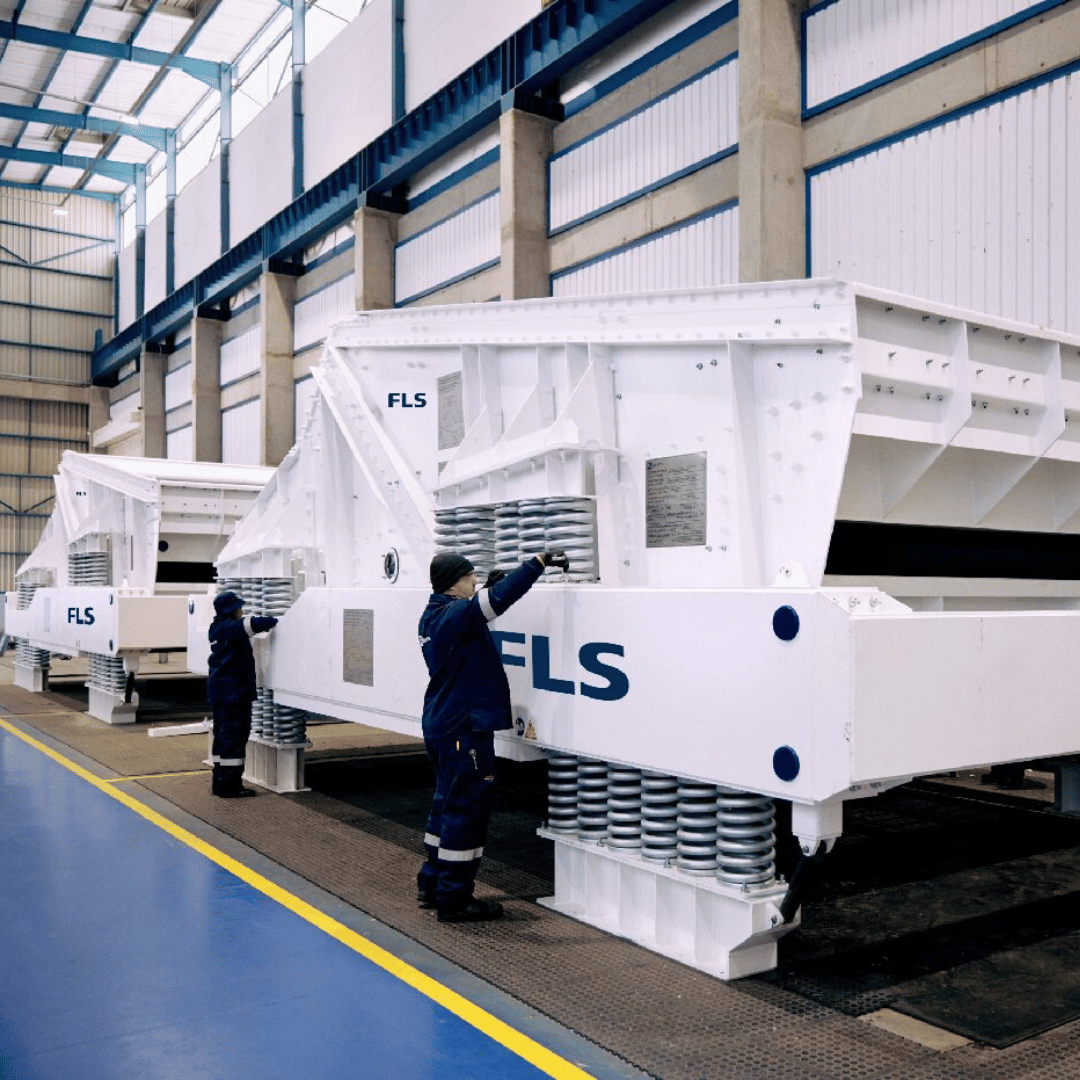

Maximise equipment uptime

Screen rebuilds save time and money, ensuring maximum availability of this key equipment. Screen exciters are also served by our exchange programme, which provides an immediate replacement for worn parts and refurbishes the worn components to as-new condition for reuse.

Boost flotation cell performance

Both forced air and self-aspirated flotation cells can achieve significant performance improvements with upgrades from FLS. The WEMCO® II upgrade for WEMCO flotation cells benefits from improved wear life and better material recovery, while the nextSTEP™ Rotor/Stator enables improved recovery capability in forced air applications, in addition to saving power and extending wear parts life.

Enhance filtration efficiency

Increase throughput and cake mass per cycle with filtration upgrades like the MAXA™ Filter Plate, which enables greater productivity and improved wear life. Our drum filter rebuilds service also extends filter life and improves reliability, supporting increased productivity.

Maximise water recovery

Thickener upgrades have shown to improve water recovery by up to 46% in real world applications. Our solutions include dilution system upgrades, feed well upgrades, drive upgrades, rake design upgrades and instrumentation upgrades. Thickener rebuilds support overall process plant availability and avoid extensive downtime due to thickener component failure which could otherwise be avoided through proactive action.