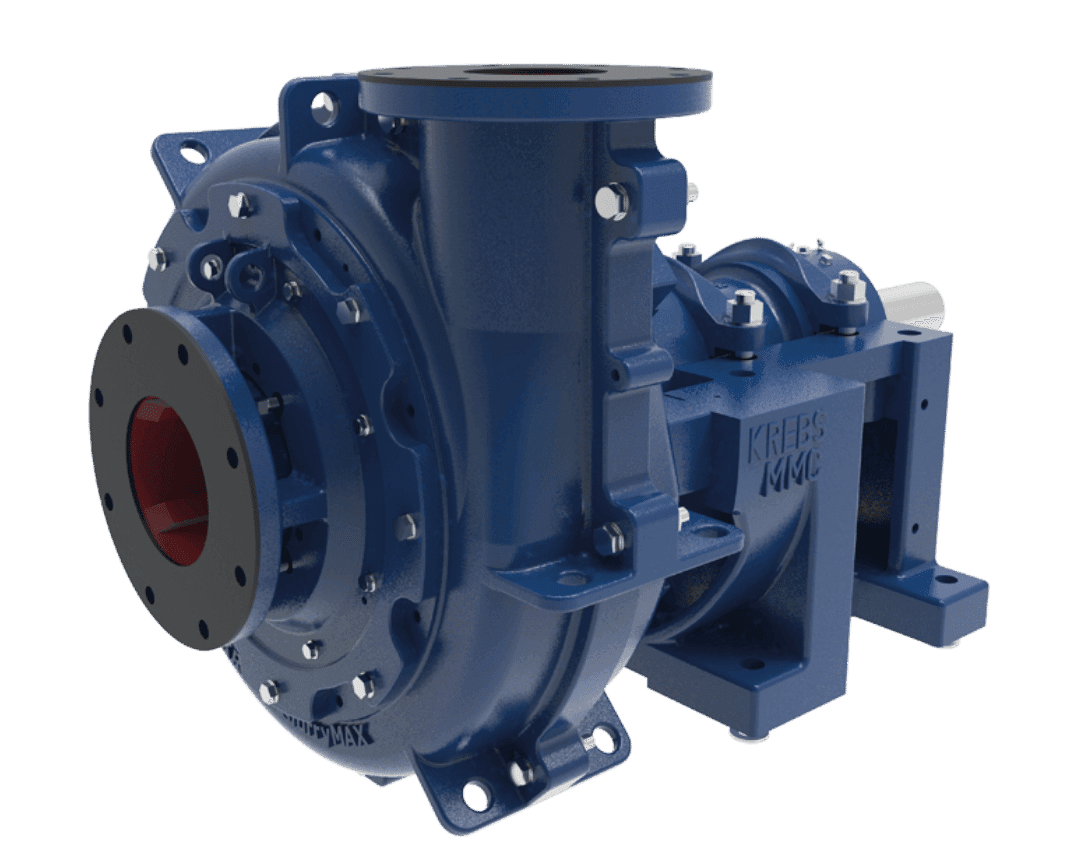

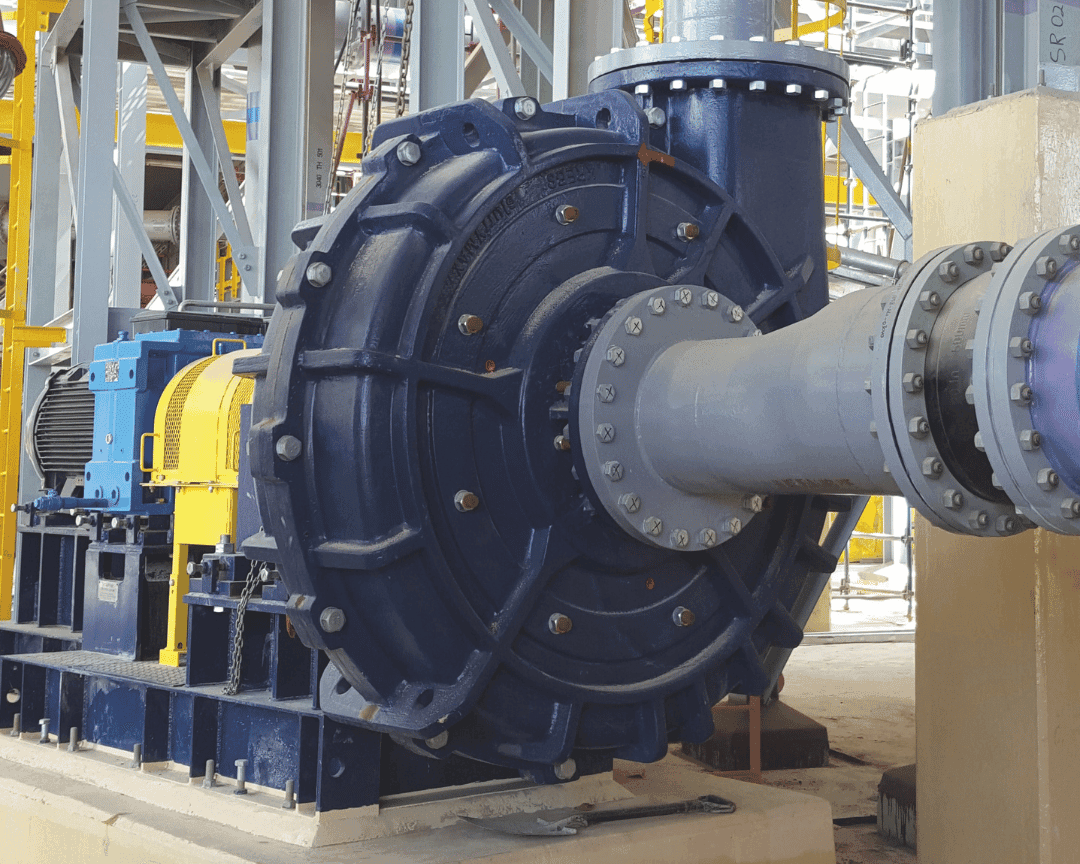

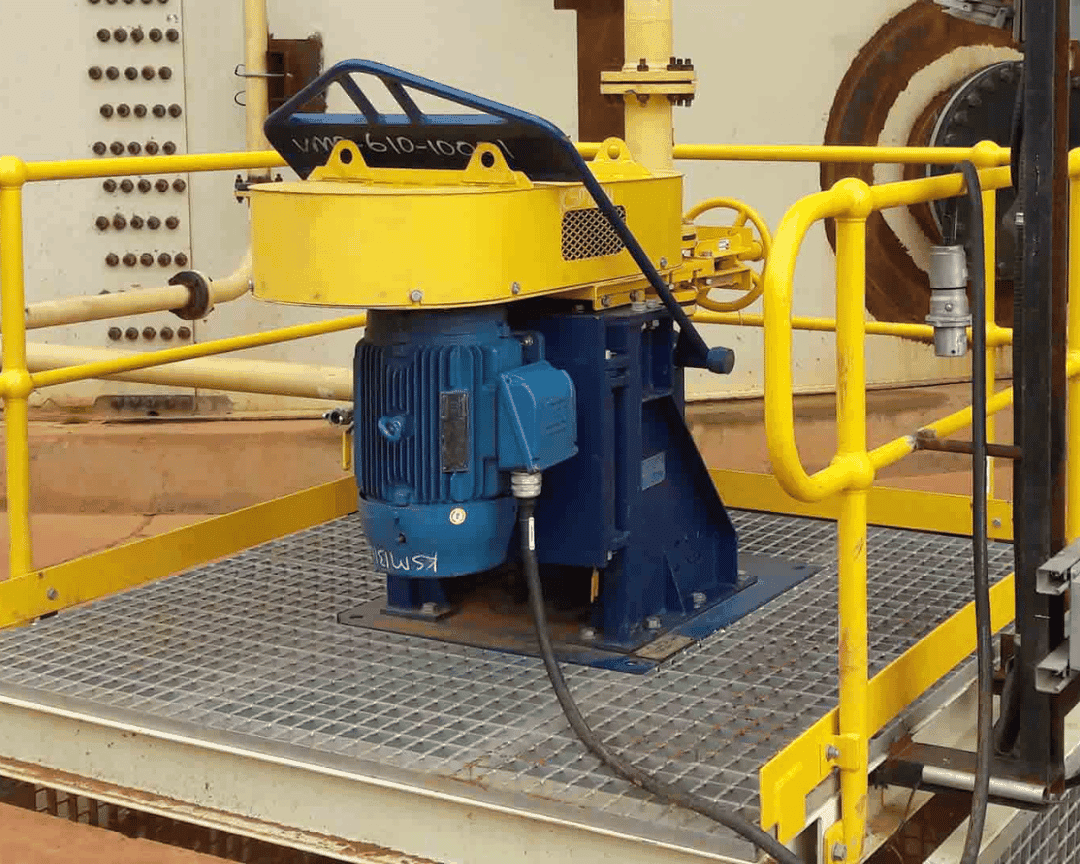

Reduce air locking

Air locking results in decreased pump efficiency, and wear. KREBS froth pumps reduce air locking, with hMAX and vMAX pumps featuring a recessed impeller that allows clear passage of entrained air, even at high froth factors. This is the important notes of the consequences of air locking a pump: It is critical to keep air out of a pump.