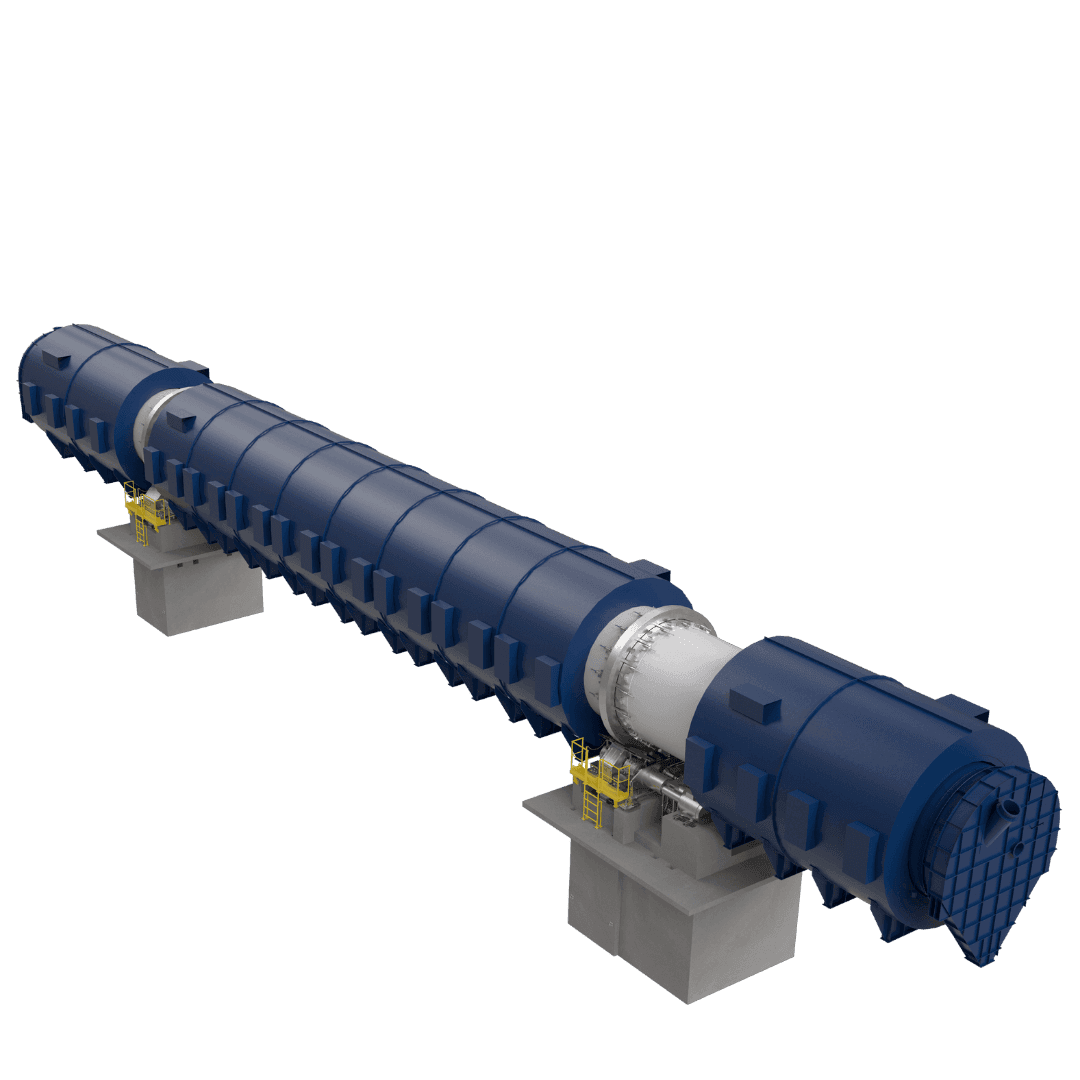

Our indirect rotary kilns can handle a wide range of raw materials – from alumina and bauxite to vanadium salts, and many in between, including the highly effective treatment of beta spodumene in lithium processing applications, and the calcination of minerals up to 800°C. We can deliver kilns from 1m to 6m diameter and up to 90m long. Lower-temperature units are available with natural gas heating in the event electric heating is not a viable option.

Minimal maintenance requirements

The heavy-duty, yet simple, construction of our indirectly fired rotary kilns ensures low annual and online maintenance requirements. This includes an automatic lubrication system, designed to facilitate the continuous movement of rotating parts while limiting component wear.