Enhance laboratory safety

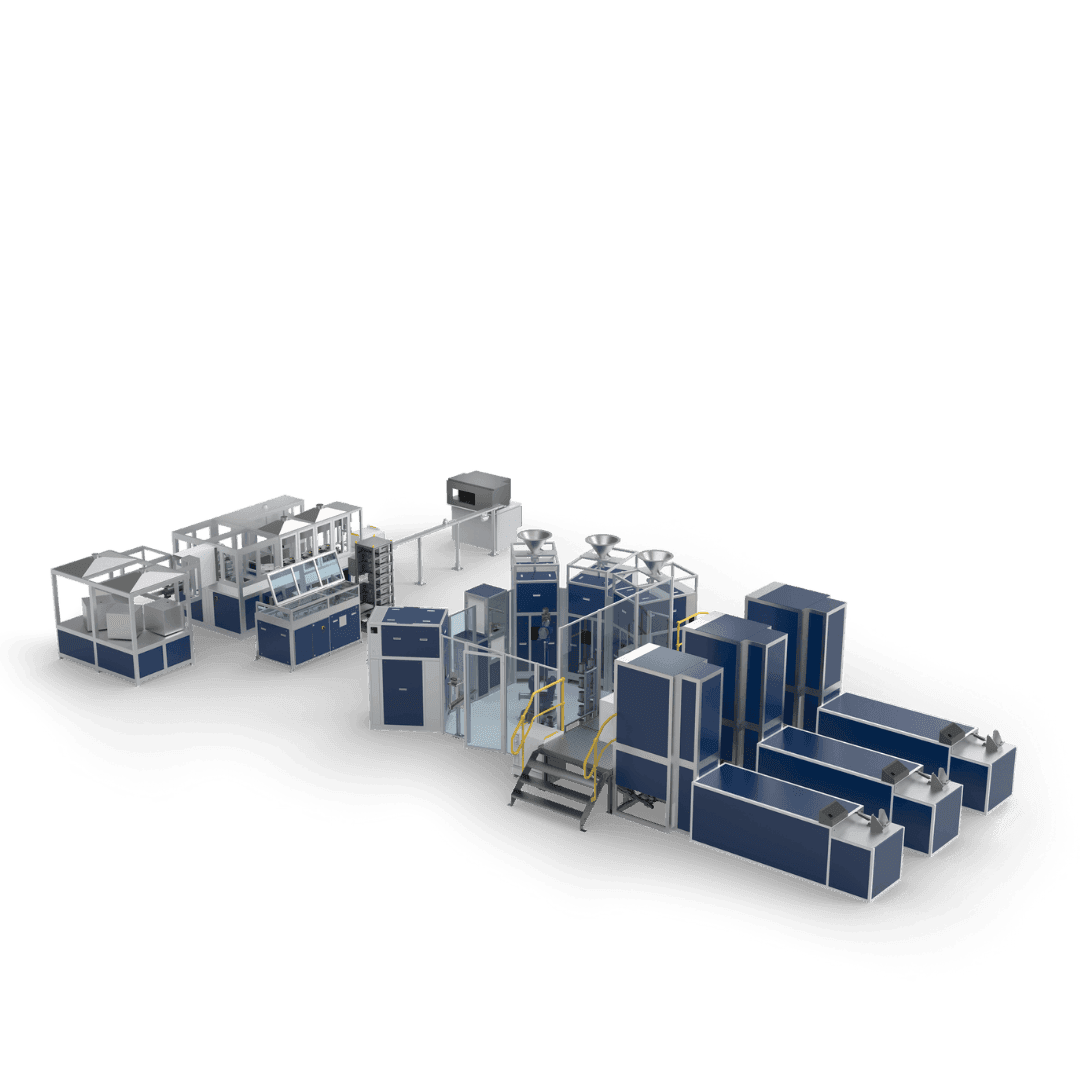

Mining labs are hazardous places, with dangers including loud noises, high temperatures, and acidic fumes – not to mention moving parts and risks associated with handling potentially heavy samples. Reducing human presence in the laboratory is a simple but effective way to reduce those health and safety risks. An automated laboratory does that by default.